- Summary

- Table Of Content

- Methodology

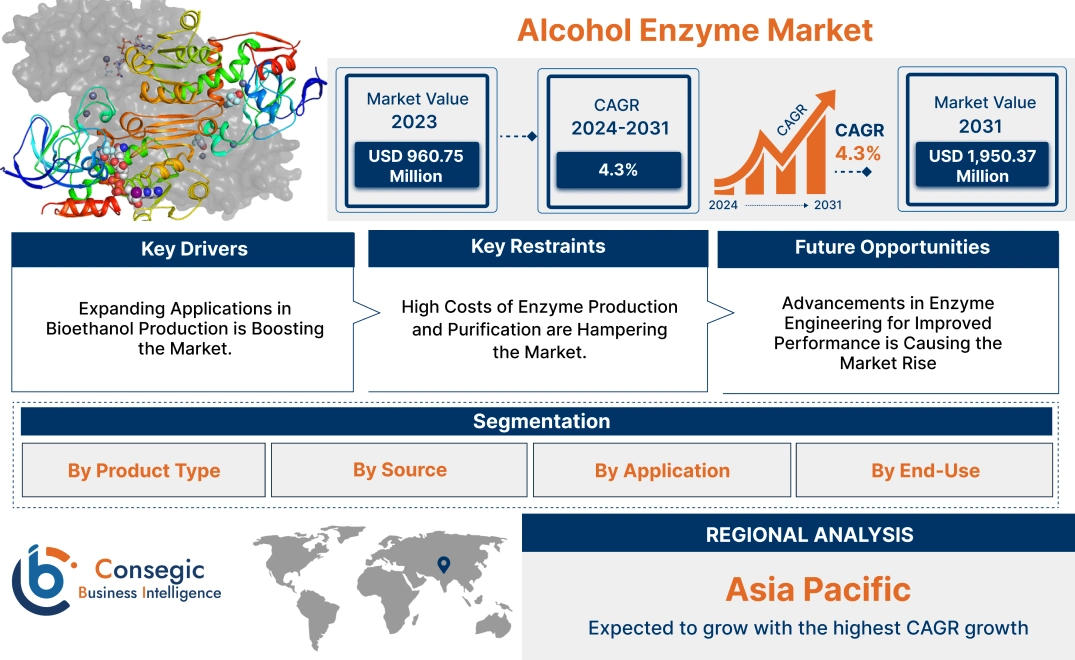

Alcohol Enzyme Market Size:

Alcohol Enzyme Market size is estimated to reach over USD 1,447.76 Million by 2031 from a value of USD 960.75 Million in 2023 and is projected to grow by USD 994.17 Million in 2024, growing at a CAGR of 5.26% from 2024 to 2031.

Alcohol Enzyme Market Scope & Overview:

The alcohol enzyme is used in the production and processing of alcohols across industries such as food and beverages, pharmaceuticals, and biofuels. These enzymes, including amylases, cellulases, and alcohol dehydrogenases, catalyze biochemical reactions to enhance efficiency and yield during fermentation, distillation, and refinement processes. Key characteristics of the market include high specificity, stability under varying conditions, and compatibility with large-scale industrial processes. The benefits include improved production efficiency, cost-effectiveness, and support for sustainable manufacturing practices. Applications span alcoholic beverage production, bioethanol synthesis, and pharmaceutical alcohol preparation. End-users include breweries, distilleries, biofuel manufacturers, and pharmaceutical companies, driven by increasing demand for high-quality alcohol products, advancements in enzyme technology, and the global push toward environmentally sustainable production methods.

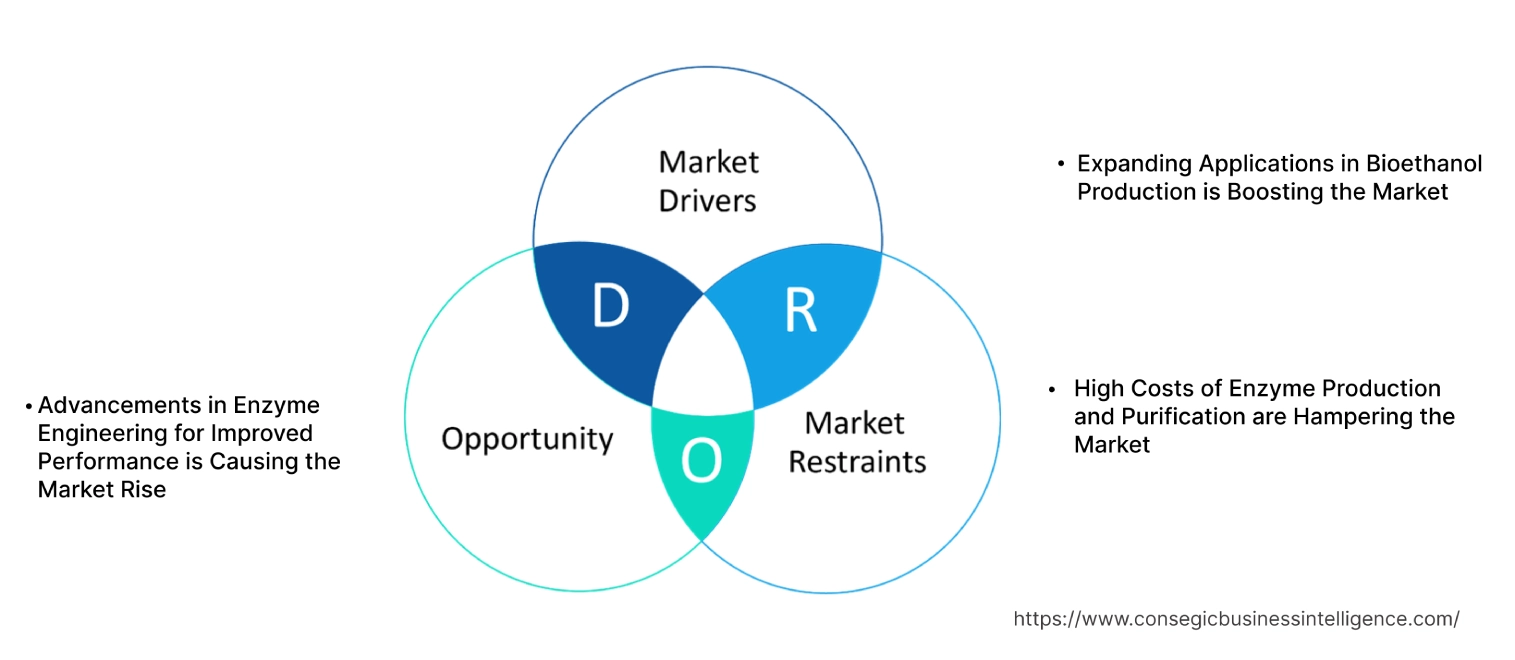

Key Drivers:

Expanding Applications in Bioethanol Production is Boosting the Market.

Alcohol enzymes, particularly alcohol dehydrogenase, are pivotal in the bioethanol production process, catalyzing the conversion of biomass into ethanol. This application aligns with global efforts to adopt renewable energy sources and reduce carbon emissions, as bioethanol serves as a sustainable alternative to fossil fuels. The use of enzymes enhances the efficiency of fermentation processes, enabling higher yields from agricultural residues and other biomass sources.

Trends in clean energy solutions and the circular economy highlight the growing emphasis on bioethanol as a key component of sustainable energy strategies. Innovations in second-generation biofuels, derived from non-food biomass, further underscore the critical role of enzymes in improving scalability and cost-efficiency. As industries seek to align with environmental regulations and reduce dependency on fossil fuels, alcohol enzymes are becoming integral to advancing bioethanol technologies.

Key Restraints :

High Costs of Enzyme Production and Purification are Hampering the Market.

The production and purification of alcohol enzymes involve complex fermentation processes and advanced downstream techniques, leading to high manufacturing costs. These expenses can be attributed to the need for precise conditions, such as specific substrates and controlled fermentation environments, to ensure enzyme activity and purity. Additionally, scaling production for industrial applications adds to the financial burden, particularly for smaller producers or emerging markets.

The cost challenges are further compounded by the specialized equipment and skilled personnel required to optimize production. This restraint limits the accessibility of enzymes in cost-sensitive applications and necessitates ongoing research to develop more efficient and affordable production methods. Addressing these cost barriers is essential for enabling broader industrial adoption and supporting sustainable production practices.

Future Opportunities :

Advancements in Enzyme Engineering for Improved Performance is Causing the Market Rise

Recent advancements in enzyme engineering have opened new possibilities for enhancing the performance of alcohol enzymes in industrial applications. Techniques such as protein engineering and immobilization allow the development of enzymes with improved stability, activity, and substrate specificity. These engineered enzymes are capable of maintaining efficiency under extreme industrial conditions, such as high temperatures and variable pH levels, overcoming traditional limitations.

Immobilization technologies also enable enzymes to be reused across multiple production cycles, reducing costs and waste. Trends in biocatalysis and green chemistry further highlight the potential of engineered enzymes to optimize production processes in industries such as biofuels, food and beverages, and pharmaceuticals. By aligning with sustainability goals and operational efficiency, enzyme engineering advancements are paving the way for innovative applications across diverse sectors.

Alcohol Enzyme Market Segmental Analysis :

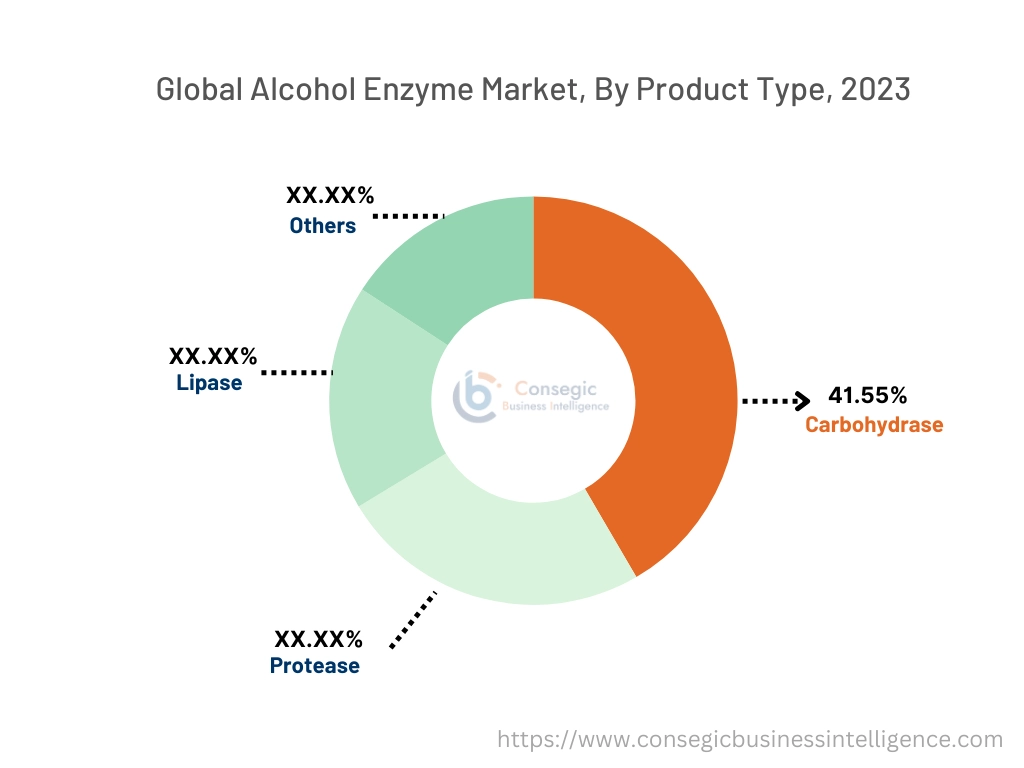

By Product Type:

Based on product type, the market is segmented into carbohydrase, protease, lipase, and others.

The carbohydrase segment accounted for the largest revenue of 41.55% in the alcohol enzyme market share in 2023.

- Carbohydrase enzymes are widely utilized in the production of alcoholic beverages, particularly in brewing and bioethanol production, due to their ability to break down carbohydrates into fermentable sugars.

- These enzymes play a critical role in improving yield, reducing production time, and enhancing the overall efficiency of fermentation processes.

- Their extensive use in beer, wine, and spirits manufacturing, as well as in bioethanol production, has driven their dominance in the market.

- Additionally, advancements in enzyme technology and the increasing alcohol enzyme market opportunities of carbohydrase enzymes in industrial applications further strengthen their position as the largest revenue-generating segment.

The lipase segment is anticipated to register the fastest CAGR during the forecast period.

- Lipase enzymes are gaining traction in distilling and other alcohol production processes due to their ability to enhance flavor profiles and improve product quality.

- They are increasingly being used in the production of specialty alcoholic beverages and biofuels.

- Additionally, the growing demand for customized alcoholic products and the integration of lipase in innovative fermentation processes are key factors driving their rapid surge.

- As consumer preferences shift toward premium alcoholic beverages with distinct flavors, the analysis depicts the rise in lipase enzymes is expected to grow significantly.

By Source:

Based on source, the market is segmented into microbial, plant, and animal.

The microbial segment accounted for the largest revenue share in 2023.

- Microbial enzymes are extensively used in the alcohol industry due to their high efficiency, cost-effectiveness, and ease of production.

- These enzymes, derived from fungi and bacteria, play a pivotal role in industrial-scale fermentation processes, particularly in brewing and bioethanol production.

- The ability of microbial enzymes to operate under diverse environmental conditions and their scalability in industrial applications have made them the preferred choice in the market.

- Increasing opportunities for investments in microbial enzyme research and production further contribute to the dominance of this segment.

The plant-based enzyme segment is anticipated to register the fastest CAGR during the forecast period.

- Plant-based enzymes, derived from sources such as barley and wheat, are gaining popularity due to their natural origin and sustainable production.

- These enzymes are particularly used in brewing and bioethanol production, where sustainability and environmental considerations are becoming critical.

- The rising trend toward clean-label products in the food and beverage industry has also fueled alcohol enzyme market trends for plant-based enzymes.

- With growing awareness of eco-friendly production practices and consumer preferences for natural ingredients, the plant-based enzyme segment is expected to witness rapid alcohol enzyme market growth.

By Application:

Based on application, the market is segmented into brewing, distilling, bioethanol production, medical diagnostics, and others.

The brewing segment accounted for the largest revenue in alcohol enzyme market share in 2023.

- Brewing relies heavily on alcohol enzymes, particularly carbohydrase and protease, to improve fermentation efficiency and enhance product quality.

- These enzymes facilitate the breakdown of complex carbohydrates and proteins, resulting in better flavor, clarity, and stability in beverages like beer and wine.

- The growing consumption of alcoholic beverages, particularly in emerging markets, and the increasing alcohol enzyme market demand for craft beers have further boosted the adoption of enzymes in brewing.

- Additionally, innovations in enzyme formulations tailored for brewing are contributing to the segment’s strong performance in the market analysis.

The bioethanol production segment is anticipated to register the fastest CAGR during the forecast period.

- Bioethanol production, driven by the global shift toward renewable energy sources, is experiencing significant advancement.

- Enzymes such as carbohydrase and lipase are critical in converting biomass into fermentable sugars for bioethanol production.

- The adoption of advanced enzyme technologies for improving conversion efficiency and reducing production costs is driving demand in this segment.

- Furthermore, government initiatives promoting biofuels as a sustainable alternative to fossil fuels are expected to propel the growth of the bioethanol production segment during the forecast period.

By End-Use:

Based on end-use, the market is segmented into food & beverage, biofuel, cosmetics, chemicals, pharmaceuticals, and others.

The food & beverage segment accounted for the largest revenue share in 2023.

- Alcohol enzymes are extensively used in the food and beverage industry for producing alcoholic beverages, improving fermentation processes, and enhancing flavor and quality.

- The rising trends for premium alcoholic beverages, such as craft beers and specialty wines, have driven the adoption of enzymes in this sector.

- Additionally, the increasing opportunities to focus on innovation in beverage production and the growing consumer preference for natural and high-quality products are fueling the trends of this segment.

- The food and beverage sector's analysis reliance on enzymes for improving productivity and meeting evolving consumer demands solidifies its dominance in the market.

The biofuel segment is anticipated to register the fastest CAGR during the forecast period.

- The biofuel sector, particularly bioethanol production, is witnessing rapid growth due to the global emphasis on renewable energy sources and reducing carbon emissions.

- Alcohol enzymes, especially carbohydrase and lipase, play a critical role in the efficient conversion of biomass into bioethanol.

- Government regulations and incentives promoting biofuel production, coupled with advancements in enzyme technology for improving conversion rates, are driving the adoption of enzymes in this sector.

- The increasing alcohol enzyme market demand for sustainable and eco-friendly fuel alternatives is expected to propel the biofuel segment significantly.

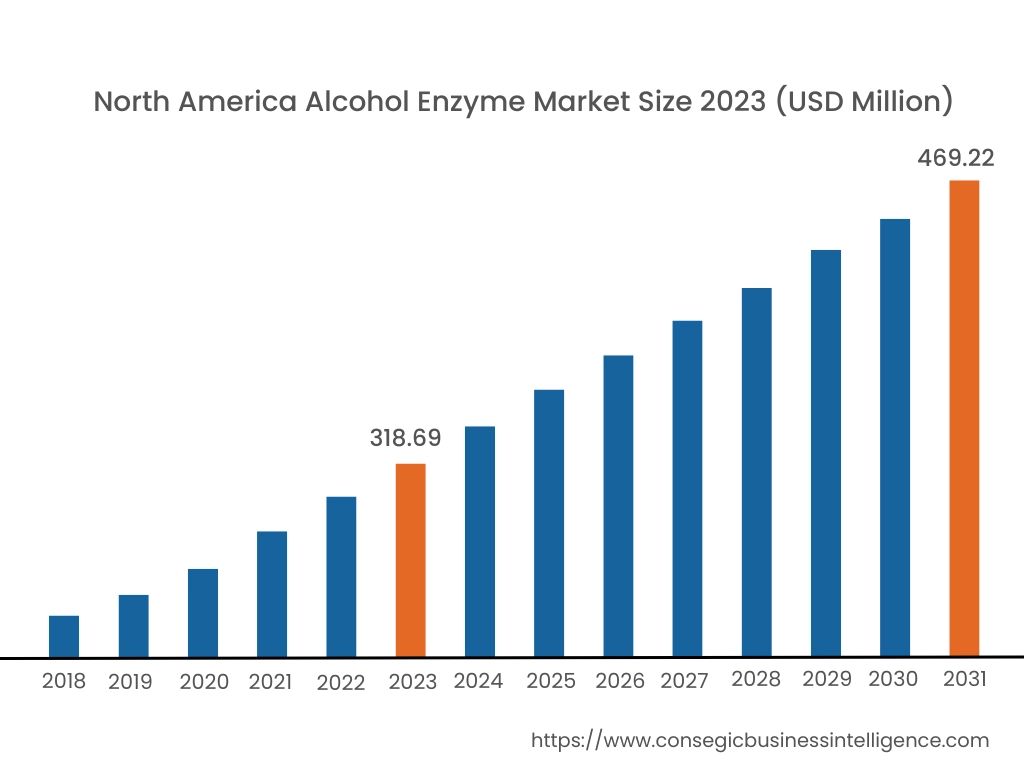

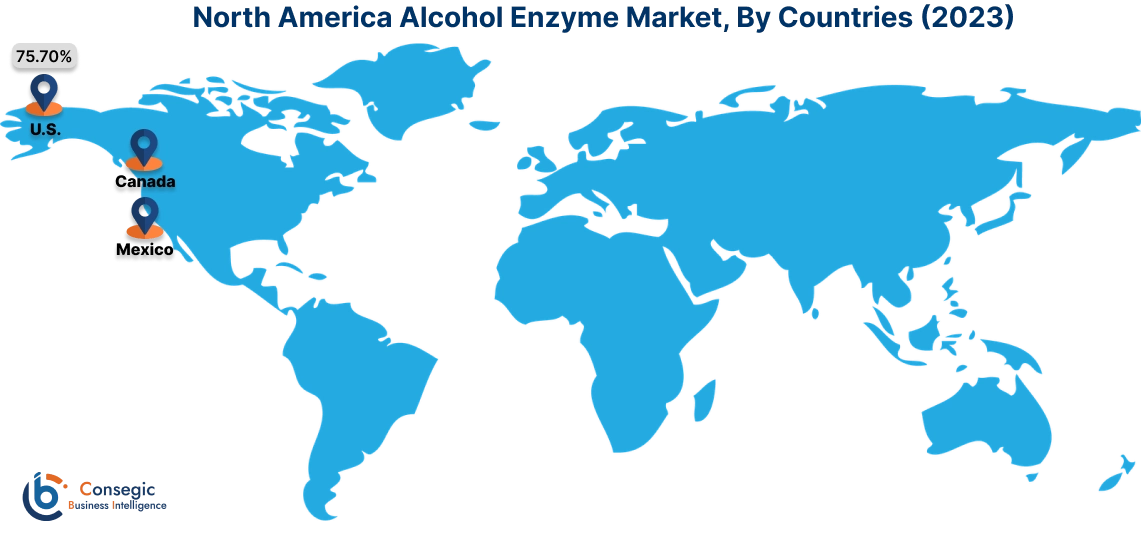

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 318.69 Million and is expected to reach USD 469.22 Million in 2031. In North America, the U.S. accounted for the highest share of 75.70% during the base year of 2023. North America holds a significant share in the alcohol enzyme market analysis, driven by its advanced biofuel sectors and robust beverage production sector. The U.S. leads the region with extensive use of alcohol enzymes such as amylases and zymases in ethanol production and the brewing of beer and spirits. The growing demand for bioethanol as a renewable energy source further supports alcohol enzyme market expansion. Canada contributes through the increasing adoption of enzymes in craft beer production and bioethanol manufacturing. However, high production costs and strict regulations on enzyme usage in industrial applications may pose challenges.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.7% over the forecast period. Asia-Pacific is the fastest-growing region in the alcohol enzyme market analysis, fueled by rapid industrialization, increasing alcohol consumption, and the expansion of biofuel production in China, India, and Japan. China leads the market with extensive use of enzymes in large-scale alcohol and ethanol production, driven by its growing energy needs and trends for alcoholic beverages. India’s expanding beverage sector and bioethanol initiatives support the adoption of alcohol enzymes for fermentation and distillation. Japan focuses on high-precision enzymatic processes for premium alcoholic beverages such as sake. However, challenges such as fluctuating raw material availability and limited awareness of advanced enzyme applications in some areas may hinder the alcohol enzyme market growth.

Europe is a prominent market for alcohol enzymes, supported by the region’s focus on sustainable energy and advanced brewing industries. Countries like Germany, France, and the UK are major contributors. Germany’s strong brewing tradition and bioethanol production drive the adoption of enzymes for fermentation and starch conversion. France emphasizes enzyme use in high-quality wine and spirit production, while the UK focuses on expanding craft breweries and distilleries that utilize advanced enzymatic processes. However, stringent EU regulations on enzyme approval and usage may create compliance challenges for manufacturers.

The Middle East & Africa region analysis is witnessing steady growth in the alcohol enzyme market, driven by increasing trends for enzymes in the beverage and biofuel sectors. In the Middle East, countries like Saudi Arabia and the UAE are adopting enzymatic processes in non-alcoholic beverage production and bioethanol initiatives. In Africa, South Africa is a key market, leveraging alcohol enzymes in the brewing and winemaking industries to enhance production efficiency and product quality. However, limited local enzyme manufacturing capabilities and reliance on imports may constrain broader alcohol enzyme market expansion in the region.

Latin America is an emerging market, with Brazil and Mexico leading the region. Brazil’s strong bioethanol sectors, supported by its large sugarcane production, drive for alcohol enzymes market trends in ethanol fermentation. Mexico’s growing alcoholic beverage sectors, particularly in tequila and beer production, support the use of enzymes to improve fermentation efficiency. The region is also exploring enzyme applications in sustainable energy production and industrial alcohol processes. However, economic instability and inconsistent regulatory frameworks may pose challenges to market growth in certain countries.

Top Key Players and Market Share Insights:

The Alcohol Enzyme market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global alcohol enzyme market. Key players in the alcohol enzyme alcohol enzyme market include -

- Novozymes A/S (Denmark)

- Royal DSM (Netherlands)

- Creative Enzymes (U.S.)

- Laffort (France)

- Biotechnology Research and Information Network AG (Germany)

- DuPont de Nemours Inc. (U.S.)

- BASF SE (Germany)

- Advanced Enzyme Technologies Ltd. (India)

- Associated British Foods Plc (U.K.)

- Kerry Group Plc (Ireland)

Alcohol Enzyme Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 1,950.37 Million |

| CAGR (2024-2031) | 4.3% |

| By Product Type |

|

| By Source |

|

| By Application |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected market size of the Alcohol Enzyme Market by 2031? +

Alcohol Enzyme Market size is estimated to reach over USD 1,447.76 Million by 2031 from a value of USD 960.75 Million in 2023 and is projected to grow by USD 994.17 Million in 2024, growing at a CAGR of 5.26% from 2024 to 2031.

What are the primary drivers for the growth of the Alcohol Enzyme Market? +

The market growth is driven by the expanding applications of alcohol enzymes in bioethanol production, increasing demand for premium alcoholic beverages, advancements in enzyme technology, and the global push toward sustainable manufacturing practices.

What are the key applications of alcohol enzymes? +

Key applications include brewing, distilling, bioethanol production, medical diagnostics, and industrial alcohol processing.

Which product type holds the largest market share? +

The carbohydrase segment accounts for the largest market share due to its extensive use in brewing and bioethanol production for breaking down carbohydrates into fermentable sugars.