Aircraft Paint Market Size:

Aircraft Paint Market size is growing with a CAGR of 3.3% during the forecast period (2025-2032), and the market is projected to be valued at USD 2,790.42 Million by 2032 from USD 2,173.25 Million in 2024.

Aircraft Paint Market Scope & Overview:

Aircraft paint is a specialized coating designed to protect and enhance the performance of aircraft. It is designed to withstand the harsh conditions of flight. It provides resistance to extreme temperatures, UV radiation, corrosion, and chemical exposure. Common types of paint used in aircraft include polyurethane, epoxy, acrylic, and enamel. It is applied to both the exterior and interior surfaces to reduce drag and improve aerodynamics. These paintsused for branding and identification purposes. Airlines typically have unique paint schemes and logos, while military aircraft have specific paint patterns. Moreover, these paints extend aircraft lifespan by maintaining structural integrity, and reducing maintenance costs, while improving aesthetics. It also ensures compliance with regulatory standards and environmental regulations. These paints are used for military aircraft and commercial aircraft such as cargo aircraft, narrow-body aircraft, propeller aircraft, and jet aircraft amongst others. Moreover, these paints are used by original equipment manufacturers (OEM), and maintenance, repair, and overhaul (MRO).

Aircraft Paint Market Dynamics – (DRO):

Key Drivers:

Technological Advancements is Accelerating Aircraft Paint Market Expansion

Aircraft paint has seen significant technological advancements to meet the evolving needs of the aviation sector. One of the key innovations is nanotechnology, which has introduced self-healing coatings that repair minor scratches and improve longevity. Nanoparticle paint is much lighter than traditional paint, potentially reducing the weight by up to 90%.

Moreover, manufacturers are focusing on manufacturing environmentally friendly coatings with reduced VOC as they provide multiple benefits.

- For instance, according to an article published by PAG, a manufacturer of aircraft parts, in 2024, low-VOC and VOC-free coatings are environmentally friendly alternatives to traditional paints that contain high levels of volatile organic compounds (VOCs). These coatings reduce air pollution and associated health risks by minimizing harmful emissions. They also offer superior performance, including enhanced durability and weather resistance. Growing consumer awareness of sustainability has led to an increased need for such types of paints, thus driving the market.

Additionally, the development of lightweight coating helps reduce the overall weight of the aircraft, improving fuel efficiency and reducing operating costs.

Overall, the convergence of nanotechnology, eco-friendly formulations, and lightweight coatings, is significantly boosting the aircraft paint market expansion.

Expanding maintenance, repair, and overhaul (MRO) facilities are Driving the Market.

MRO facilities are specialized centers that provide essential services to maintain, repair, and ensure the operational readiness of various assets, including commercial and military aircraft. These facilities handle tasks such as inspections, part replacements, system upgrades, and cosmetic restorations, including repainting. Over time, exposure to environmental factors such as UV radiation, moisture, and pollutants degrade paint, leading to corrosion or diminished brand appearance.

Repainting helps restore the protective coating, ensuring longevity and improved performance. Moreover, for aircraft, repainting also improves aerodynamics by reducing surface irregularities caused by wear and tear. Furthermore, updated paint schemes align assets with new corporate branding, improving market perception and reinforcing a consistent brand identity. Also, overall, repainting enhances durability, safety, and aesthetics, ensuring operational efficiency. The increasing age of global aircraft fleets, stringent regulatory requirements, and the introduction of new aircraft models have led to an increase in MRO facilities.

- For instance, in September 2024, Woodward, Inc. announced the successful completion of its new aerospace MRO facility in Illinois, USA. Thus, this has required an increased need for paints for repainting services, positively influencing aircraft paint market trends.

Overall, the growing need for MRO services, driven by aging aircraft fleets and stricter regulations, is accelerating the global aircraft paint market growth.

Key Restraints :

Stringent Regulations is Hampering the Aircraft Paint Market Demand

The market faces significant restraints due to stringent environmental and safety regulations. Globally, regulatory bodies such as the Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) enforce strict guidelines to minimize the use of hazardous materials, such as volatile organic compounds (VOCs), heavy metals, and other toxic substances in paint formulations. Compliance with these regulations necessitates the development of eco-friendly alternatives, which are expensive and require significant research and development investments.

Additionally, manufacturers must adhere to aviation-specific standards set by organizations such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), which mandate rigorous testing and certification for new paint technologies. These processes increase production costs and lengthen product development timelines, further hindering aircraft paint market trends. Furthermore, the frequent updates to regulatory frameworks create uncertainty, compelling manufacturers to continuously adapt their formulations, thereby impacting profitability and delaying product launches.

Overall, analysis shows that the stringent environmental and safety regulations, coupled with complex certification processes and frequent regulatory updates, pose significant challenges, hampering the aircraft paint market demand.

Future Opportunities:

Increase in Fleets is Expected to Increase Aircraft Paint Market Opportunities.

A fleet refers to a group of aircraft owned and operated by a company, government, or leasing company. Multiple factors are responsible for the fleet production increase. As air travel requirements grow, airlines need more aircraft to accommodate the rising number of passengers. Moreover, regional connectivity initiatives aim to stimulate economic growth and social development in underserved regions by improving air transportation.

Additionally, airlines expand their operations to new destinations, requiring additional aircraft to serve these routes. Expanding trade and tourism encourages investment in additional aircraft. Furthermore, the growth of e-commerce and global trade has increased the need for air cargo, leading to the increase of cargo fleets.

- For instance, in October 2024, Emirates SkyCargo, the cargo division of the world's largest international airline, intends to almost double its current fleet of 11 freighters by operating 21 777 Freighters in the coming years. Thus, this will require significant quantities of durable, and corrosion-resistant paint for painting new aircraft, maintenance, and branding updates, creating the potential for the upcoming years.

Overall, the increasing need for air travel, coupled with fleet expansion and modernization initiatives, is expected to increase aircraft paint market opportunities.

Aircraft Paint Market Segmental Analysis :

By Aircraft Type:

Based on aircraft type, the market is categorized into commercial aircraft and military aircraft.

Trends in Aircraft Type:

- Increased narrow-body commercial aircraft production drives the significant need for paint.

- Advancements in stealth technology are driving the need for specialized paints that reduce radar visibility.

The commercial aircraft segment accounted for the largest market share in 2024.

- A commercial aircraft is a plane designed for transporting passengers or cargo over short, medium, or long distances. These aircraft, operated by airlines or logistics companies, include models such as narrow-body jets, wide-body jets, and freighters.

- Paint is applied to the fuselage, wings, tail, and engine components of commercial aircraft. It covers both the exterior and interior areas. Specialized coatings are also used on high-temperature zones such as engine inlets.

- Paints used in aircraft provide essential protection against corrosion, weathering, UV radiation, and chemical exposure, extending the lifespan of the aircraft. It improves aerodynamics by creating a smoother surface, reducing drag, and enhancing fuel efficiency.

- Increasing global air travel needs, economic increase, and expanding middle-class populations have led to an increase in commercial aircraft production.

- For instance, Airbus successfully ramped up production of the A330 (a wide-body aircraft) to approximately three aircraft per month by the end of 2022. The company is to further increase production to four aircraft per month in 2024. This has driven the need for specialized paints to meet the specific needs of these aircraft.

- Overall, the increasing need for air travel, coupled with stricter regulatory standards, is driving the segment in the aircraft paint market growth.

The military aircraft segment is expected to grow at the fastest CAGR over the forecast period.

- Military aircraft are specialized planes designed for defense, reconnaissance, combat, or transport purposes. They include fighters, bombers, surveillance planes, and helicopters, each tailored for specific missions such as air superiority, ground attacks, troop movement, or intelligence gathering.

- Military aircraft are coated with specialized paints that enhance performance, durability, and operational effectiveness. Moreover, camouflage patterns allow the aircraft to blend into the environment, hindering detection from the ground or air.

- Additionally, specialized coatings are used to enhance stealth capabilities, reducing the aircraft's visibility to radar and infrared sensors. These coatings serve multiple purposes. Camouflage blends aircraft with surroundings for stealth. Reduces radar detectability, aiding stealth missions.

- Furthermore, these paints manage heat dissipation and reduce infrared signatures. Also, resists scratches, impacts, and wear during high-speed operations.

- As per the market analysis, rising geopolitical tensions, increasing defense budgets, and technological advancements are leading to increased manufacturing, thus driving the segment in the market for the forecasted years.

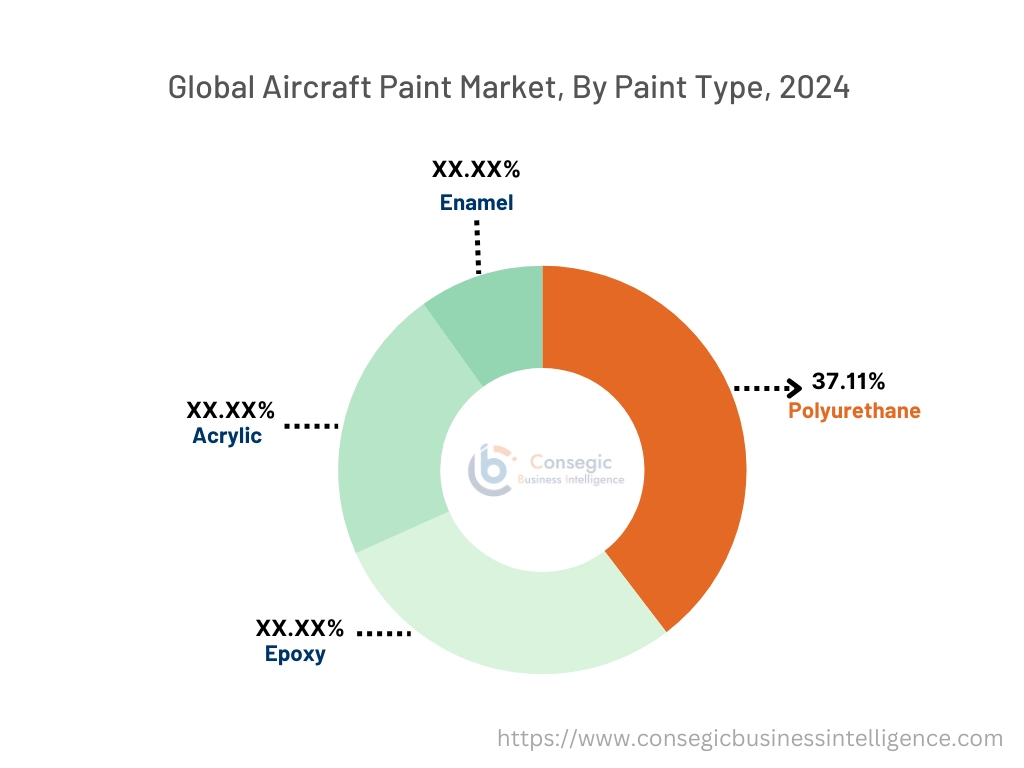

By Paint Type:

The paint type segment is categorized into polyurethane, epoxy, acrylic, and enamel.

Trends in the Paint Type

- Self-healing coatings are emerging with technology with the potential to repair minor scratches and damage.

- Growing focus on lightweight coatings to reduce aircraft weight while improving fuel efficiency.

The polyurethane segment accounted for the largest market share of 37.11% in 2024.

- Polyurethane paint is a high-performance coating widely used for aircraft exteriors due to its durability and aesthetic finish. It is a two-component system, combining a resin and a hardener, which creates a chemically resistant and flexible surface.

- This paint is a plastic-like liquid that hardens to form a tough, resilient finish that's resistant to chemicals, solvents, abrasion, rain, humidity, and the sun's UV rays. It withstands exposure to aviation fuel, hydraulic fluids, and cleaning agents without degrading.

- Moreover, its ability to expand and contract with the aircraft's surface prevents cracking or peeling. Also, it offers a high-gloss finish that maintains its appearance over time, enhancing the aircraft’s aesthetics.

- Manufacturers are focusing on developing innovative formulations that offer enhanced performance and sustainability.

- For instance, in July 2021, PPG introduced a new line of polyurethane topcoats, the PPG BOUNDLESS CA6500 series, specifically designed for general aviation. This innovative product offers a rapid and efficient solution for repainting, stripping, or touch-up services on light aircraft, minimizing downtime for aircraft owners. These product innovations are expanding the reach and driving the segment.

- Overall, as per the market analysis, technological advancements are driving this segmental growth in the aircraft paint industry.

The epoxy segment is expected to grow at the fastest CAGR over the forecast period.

- Epoxy paint used in aircraft is a highly durable and protective coating widely used in aircraft exteriors in the aviation sector. The main benefits are their versatility and bonding with various materialssuch as metal, wood, and glass, making them suitable for a range of applications. It is used as a primer.

- Epoxy paint forms a strong bond with the aircraft's surface, providing superior adhesion.They offer exceptional resistance to corrosion, protecting the aircraft's metal structure from rust and deterioration. Moreover, they are highly resistant to abrasion, impact, and chipping, maintaining their integrity over extended periods.

- Additionally, epoxy paints are resistant to a wide range of chemicals, including fuels, oils, and cleaning agents.

- The increasing requirements for durable, corrosion-resistant, and lightweight paints create potential for the segment in the upcoming years.

By End-Use:

The end-user segment is categorized into original equipment manufacturer (OEM) and maintenance, repair, & overhaul (MRO).

Trends in End-Use:

- The aging fleet requires frequent repainting and refurbishment, boosting the MRO segment.

- Increasing production of new aircraft drives requirements for high-performance, durable paints.

The original equipment manufacturer (OEM) segment accounted for the largest market share in 2024.

- An original equipment manufacturer (OEM) in the aviation sector is a company that designs, manufactures, and assembles aircraft. Major OEMs such as Boeing, Airbus, and Embraer produce a wide range of commercial and military aircraft.

- They use paint as it act as a barrier, protecting the aircraft's metal structure from corrosion caused by exposure to environmental factors such as moisture and salt. Moreover, a smooth, well-painted surface reduces drag, improving the aircraft's fuel efficiency and overall performance.

- Airlines are constantly replacing older, less efficient aircraft with newer models to improve fuel efficiency, reduce emissions, and enhance passenger experience. This drives the requirements for new aircraft production.

- For instance, in 2023, Boeing saw a production increase, delivering a total of 528 commercial aircraft, representing a 10% increase compared to the previous year. This surge in production drives the need for innovative paint formulations that offer superior performance and durability, thus driving a segment in the market.

- Overall, the increasing requirements for new aircraft from major OEMs are driving segmental growth.

The maintenance, repair, and overhaul (MRO) segment is expected to grow at the fastest CAGR over the forecast period.

- Maintenance, repair, and overhaul (MRO) is a critical service provided to aircraft to ensure their airworthiness and safety. MRO facilities perform a range of services, including routine inspections, component replacements, structural repairs, and repainting.

- Repainting is a crucial part of the MRO process.Over time, paint used in aircraft deteriorates due to exposure to various environmental factors, such as UV radiation, moisture, and chemicals.

- They use a fresh coat of paint and protect the aircraft's metal structure from corrosion and weather, extending its lifespan. Repainting restores the aircraft's appearance, improving its visual appeal and brand image.

- Repainting also ensures that markings and identification signs are clear and visible, enhancing safety during flight operations.

- According to the market analysis, as aircraft age, they require more frequent maintenance and repairs to ensure their continued airworthiness, boosting the segmental trend in the year forecasted.Additionally, advancements in aircraft technology and the introduction of new aircraft models necessitate specialized MRO services.

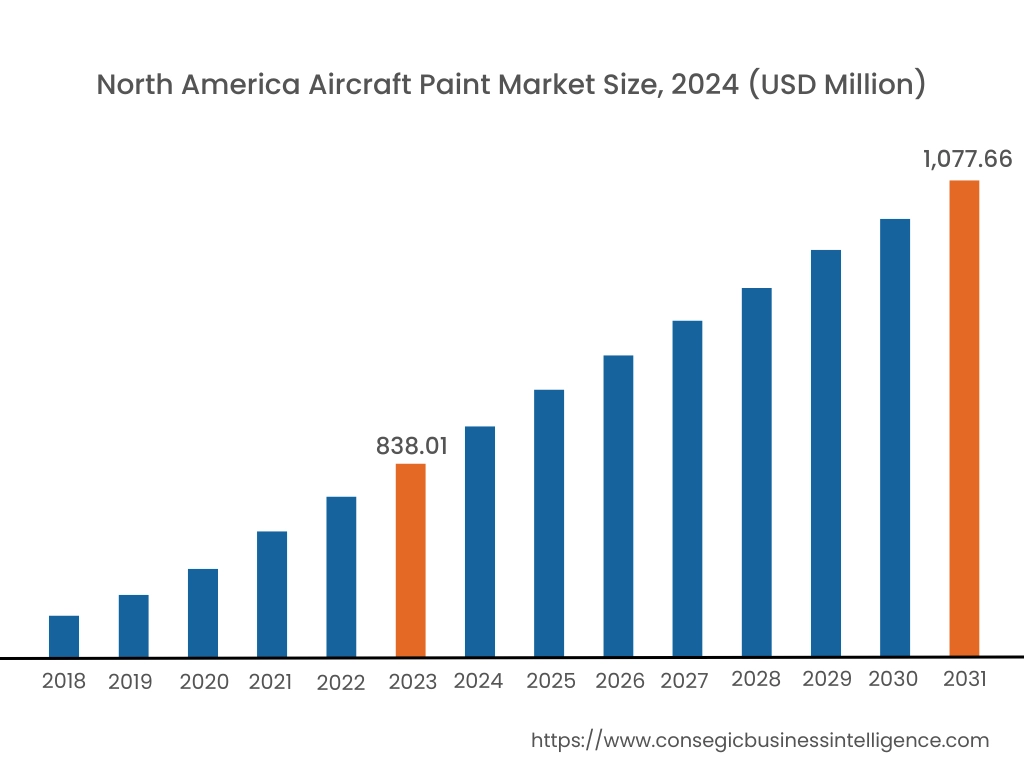

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest aircraft paint market share at 38.56% and was valued at USD 838.01 Million and is expected to reach USD 1,077.66 Million in 2032. In North America, the U.S. accounted for the highest aircraft paint market share of 73.21% during the base year of 2024. The region boasts a robust aerospace sector with major aircraft manufacturers such as Boeing and Bombardier, driving significantly the need for aircraft paint. These manufacturers are increasing production, further boosting the market.

- For instance, Bombardier experienced a significant boost in sales, increasing its jet sales by 60% in the first quarter of 2024 compared to the previous year. This has required an increased need for paintings for protection and aesthetic purposes.

Additionally, North American companies are at the forefront of technological advancements in paint formulations, application techniques, and sustainable coatings. Furthermore, a well-established supply chain of raw materials and manufacturing facilities further strengthens the region's dominance. Also, significant investments in research and development have led to the development of innovative paint solutions for the aviation sector. Overall, the robust aerospace sector in North America, driven by increased production from major manufacturers, coupled with technological advancements and a strong supply chain is driving the market in the region.

In Asia Pacific, the aircraft paint market is experiencing the fastest growth with a CAGR of 3.8% over the forecast period. APAC is witnessing a rapid economic increase, leading to increased air travel and a surge in requirements for new aircraft. This directly drives the need. Moreover, low-cost carrier (LCC) operations are gaining popularity in the region, contributing to the increasing number of aircraft in service. This trend boosts the need for paint for both new and existing aircraft. Additionally, governments in the region are investing in infrastructure development and aviation modernization, further fueling the adoption of the aviation sector and the associated need for paint used in aircraft. Furthermore, several countries in APAC are significantly increasing their military spending, leading to the procurement of new military aircraft and the need for specialized paints for military aircraft.

Europe's aircraft paint market analysis states that several trends are responsible for the progress of the market in the region. Europe boasts a well-established aerospace manufacturing sector with major players such as Airbus, driving the need for paint for both new and refurbished aircraft. Moreover, European manufacturers are increasingly prioritizing sustainable and eco-friendly paint solutions, aligning with the region's emphasis on environmental regulations and reducing the environmental impact of aviation. Additionally, adherence to stringent European Union regulations regarding paint emissions and environmental impact drives the demand for compliant and high-performance aircraft paints. Furthermore, Europe has a significant fleet of aging aircraft that require regular maintenance, repair, and overhaul (MRO) services. MRO activities, including repainting, contribute to the ongoing need for aircraft paint.

The Middle East and Africa (MEA) aircraft paint market analysis states that the region is also witnessing a notable surge. Several countries in the region, particularly the UAE, are rapidly developing into major international aviation hubs. This surge in air traffic is driving the need for new aircraft and the subsequent need for aircraft paint. Moreover, significant investments are being made to modernize airports and expand aviation infrastructure, further boosting the requirements for aircraft. The emergence of new airlines and the increase of existing fleets are contributing to the requirements of the market. Additionally, the region's affluent population and luxury travel trends are driving the demand for customized aircraft interiors, including specialized paint finishes.

Latin America's aircraft paint market size is also emerging. Many Latin American countries are popular tourist destinations, attracting millions of visitors each year. The tourism sector is driving demand for charter flights and private jets, which require specialized paint finishes. Moreover, many Latin American economies have shown signs of recovery in recent years, leading to increased business travel and cargo transportation. Governments and private investors are investing in the aviation sector, which is driving the need for new aircraft and aircraft maintenance, influencing the requirements for painting. Furthermore, growing middle-class populations and rising disposable incomes are fueling increased air travel demand. New airlines are entering the market, and existing airlines are expanding their fleets to meet the growing demand. This drives the market in the region.

Top Key Players & Market Share Insights:

The Aircraft Paint market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Aircraft Paint market. Key players in the Aircraft Paint industry include-

- AkzoNobel N.V. (Netherlands)

- PPG Industries, Inc. (U.S.)

- IHI Ionbond (Switzerland)

- BASF SE (Germany)

- Walter Wurdack Inc. (U.S.)

- Indestructible Paint (UK)

- Sherwin-Williams Company (U.S.)

- Axalta Coating System (U.S.)

- Mankiewicz Gebr. & Co. (Germany)

- Hentzen Coatings, Inc. (U.S.)

Aircraft Paint Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 (USD Million) | USD 2,790.42 Million |

| CAGR (2025-2032) | 3.3% |

| By Aircraft Type |

|

| By Paint Type |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Aircraft Paint market? +

In 2024, the Aircraft Paint market is USD 2,173.25 Million.

Which is the fastest-growing region in the Aircraft Paint market? +

Asia Pacific is the fastest-growing region in the Aircraft Paint market.

What specific segmentation details are covered in the Aircraft Paint market? +

Aircraft Type and Paint Type segmentation details are covered in the Aircraft Paint market.

Who are the major players in the Aircraft Paint market? +

AkzoNobel N.V. (Netherlands), PPG Industries, Inc. (U.S.), Sherwin-Williams Company (U.S.), Axalta Coating System (U.S.), Mankiewicz Gebr. & Co. (Germany), Hentzen Coatings, Inc. (U.S.), IHI Ionbond (Switzerland), BASF SE (Germany), Walter Wurdack Inc. (U.S.), and Indestructible Paint (UK).