- Summary

- Table Of Content

- Methodology

Aircraft Jack Market Size:

Aircraft Jack Market size is estimated to reach over USD 1,468.63 Million by 2032 from a value of USD 1,131.66 Million in 2024 and is projected to grow by USD 1,157.01 Million in 2025, growing at a CAGR of 3.6% from 2025 to 2032.

Aircraft Jack Market Scope & Overview:

Aircraft jacks refer to specialized lifting devices that are designed to raise and support various types of aircraft during maintenance, repair, and inspection activities. These jacks are designed to provide a stable and secure platform for aircraft while it is being serviced, ensuring that technicians can perform their work safely and effectively. Moreover, airplane jacks provide a range of benefits such as enhanced worker safety, increased accessibility to multiple parts of aircraft, robust design, improved operational efficiency, and others.

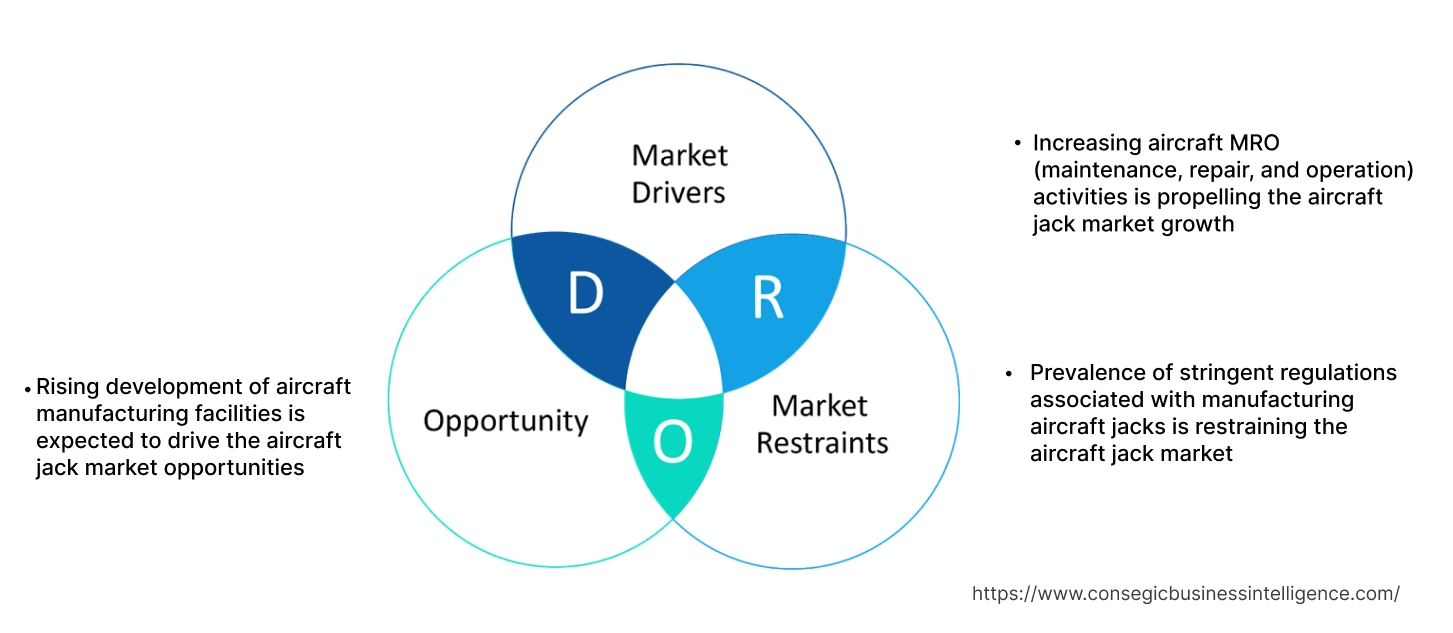

Key Drivers:

Increasing aircraft MRO (maintenance, repair, and operation) activities is propelling the aircraft jack market growth

Aircraft jacks play a crucial role in maintenance, repair, and operation (MRO) activities for aircraft. These jacks ensure safe and effective serviceability while providing access to various components of the aircraft. The jacks are primarily used to lift the aircraft off the ground, allowing maintenance personnel to safely access and inspect the undercarriage, landing gear, and wheel assemblies. Moreover, these jacks are typically used during aircraft inspection activities, component replacement, tire changes, and during operational checks where the aircraft's systems need to be tested after maintenance is performed.

- For instance, according to the International Air Transport Association (IATA), the total spending on commercial aircraft MRO activities in North America and European region was valued at approximately USD 26 billion and USD 24 billion respectively in 2023.

Therefore, the rising aircraft MRO activities is increasing the adoption of airplane jacks to ensure safe and effective serviceability while providing access to various components of the aircraft, in turn proliferating the aircraft jack market size.

Key Restraints:

Prevalence of stringent regulations associated with manufacturing aircraft jacks is restraining the aircraft jack market

The manufacturers of aircraft jack have to comply with numerous stringent standards such as ISO (International Organization for Standardization) Standard - ISO 9001, EN 1915-1, AS9100, and others, which is a primary factor constraining the market growth.

For instance, ISO 9001 standard specifies particular requirements for a quality management system. Airplane jack manufacturers must comply with the ISO standard for demonstrating the ability to consistently provide products and services that meet regulatory and customer requirements. Additionally, EN 1915-1 is a European standard that is applicable to ground support equipment including airplane jacks, which are utilized in civil air transport as intended by the manufacturer. This standard specifies safety requirements associated with the aircraft ground support equipment in general.

Further, AS9100 is an aerospace standard that is designed for achieving high-quality in the aviation, space, and defense sector. AS9100 governs any design and manufacturing of aerospace products, maintenance, along with aerospace product distribution. Hence, the prevalence of the aforementioned regulations and standards associated with manufacturing airplane jacks is hindering the aircraft jack market expansion.

Future Opportunities :

Rising development of aircraft manufacturing facilities is expected to drive the aircraft jack market opportunities

In aircraft manufacturing facilities, airplane jacks are often used at various stages of the production process to ensure that the assembly, inspection, and testing of aircraft components are conducted safely and efficiently. Airplane jacks are primarily employed in aircraft manufacturing facilities for applications involving assembly and sub-assembly operations, quality control & inspection, and testing among others.

- For instance, in October 2022, Tata Advanced Systems Limited, in partnership with Airbus Defence & Space S.A. launched its new C-295 transport aircraft manufacturing facility in Gujarat, India. The project is worth nearly USD 3 billion and includes the delivery of 56 C-295 transport aircrafts to the Indian Air force.

Hence, as per the analysis, the rising development of aircraft manufacturing facilities is projected to increase the demand for airplane jacks for ensuring that the assembly, inspection, and testing of aircraft components are conducted safely and efficiently, thereby, driving the aircraft jack market opportunities during the forecast period.

Aircraft Jack Market Segmental Analysis :

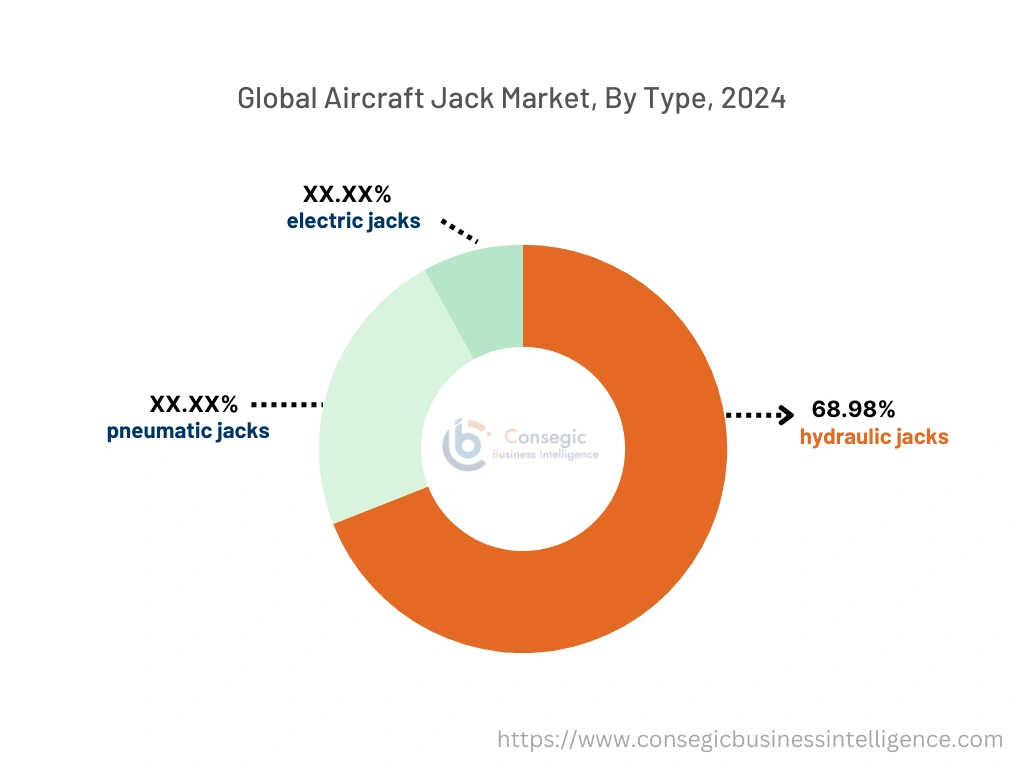

By Type:

Based on type, the market is segmented into hydraulic jacks, pneumatic jacks, and electric jacks.

Trends in the type:

- Increasing adoption of hydraulic jacks due to its several benefits including high lifting capacity, increased stability, and precise control.

- There is a rising trend towards utilization of pneumatic jacks, attributing to its lightweight and rapid lifting capability.

The hydraulic jacks segment accounted for a largest revenue share of 68.98% in the total aircraft jack market share in 2024.

- Hydraulic jacks refer to specialized lifting devices that utilize hydraulic fluid to generate force and lift heavy aircraft components during maintenance, repair, and manufacturing tasks.

- The commonly used hydraulic jacks include axle jacks and tripod jacks among others. These jacks are designed to safely elevate and support aircraft, ensuring that technicians can work on various parts of the aircraft without compromising safety or stability.

- Moreover, hydraulic jacks offer several benefits such as high lifting capacity, smooth operation, increased stability, precise control, and others.

- For instance, Tronair is an airplane jack manufacturer that offers axle and tripod hydraulic jacks in its product offerings. Tronair provides an extensive range of hydraulic jacks, including over 70 models that are compatible with more than 375 aircraft types.

- According to the aircraft jack market analysis, the rising advancements associated with hydraulic jacks are driving the market.

The pneumatic jacks segment is anticipated to register a significant CAGR growth during the forecast period.

- Pneumatic jacks are lifting devices that use compressed air to lift and support aircraft during maintenance, repair, and inspection activities.

- Pneumatic jacks operate based on the principles of pneumatic pressure, typically utilizing a simple mechanical mechanism to convert air pressure into lifting force.

- Moreover, pneumatic jacks provide a broad range of benefits including lightweight, ease of portability, increased versatility, and rapid lifting capability among others.

- For instance, JMS AG Jet offers a range of pneumatic operated aircraft jacks in its product portfolio. The pneumatic operated jacks feature high maneuverability, low maintenance requirements, and complete CE compliance.

- Thus, increasing advancements related to pneumatic jacks are anticipated to propel the market during the forecast period.

By Aircraft Type:

Based on material, the market is segmented into fixed wing and rotary wing.

Trends in the aircraft type:

- Rising adoption of fixed wing aircraft due to its longer flight range, higher speed capabilities, and, greater payload capacity.

- Factors including increasing investments in air defence platform and technological advancements in aircraft manufacturing are key determinants for driving the segmental growth of fixed wing and rotary wing aircraft.

The fixed wing segment accounted for the largest revenue in the overall market in 2024.

- Fixed wing aircraft refers to a type of aircraft with wings that remain stationary while generating the aircraft's lift.

- Fixed wing aircraft is capable of flight using wings that produce lift generated by the aircraft's forward air speed and the shape of the wings.

- Moreover, fixed wing aircraft offers a range of benefits including longer flight range and endurance, higher speed capabilities, greater payload capacity, improved stability in turbulent weather conditions, along with relatively lower maintenance and operational cost among others.

- For instance, in November 2022, Aurora Flight Sciences launched its new fixed-wing eVTOL (electric vertical take-off and landing) aircraft that is specifically designed for airborne ISR (intelligence, surveillance, and reconnaissance) missions.

- Therefore, increasing advancements associated with fixed wing aircraft are driving the aircraft jack market growth.

The rotary wing segment is anticipated to register a significant CAGR growth during the forecast period.

- Rotary wing aircraft is a type of aircraft that is completely or partly sustained in the air by lifting rotors revolving around a vertical axis.

- Rotary wing aircraft typically include aircraft which consist of rotors that provide lift throughout the entire flight, such as helicopters, gyrodynes, and autogyros.

- Additionally, the primary benefits of rotary wing aircraft includes its ability to fly vertically, hover over a fixed position at a given height, and take off and land in a very small space.

- For instance, in December 2021, the French Armament General Directorate collaborated with Airbus for the procurement and development of military helicopters. The contract includes the development of 169 military helicopters specifically optimized for deployment in the French armed forces.

- Hence, the increasing development of rotary wing aircraft is anticipated to boost the aircraft jack market size during the forecast period.

By Sales Channel:

Based on sales channel, the market is segmented into direct sales and distributor sales.

Trends in the sales channel:

- Factors including the availability of excellent support and warranty, higher product quality, and reliable shipping and return policies are key prospects driving the direct sales channel segment.

- Factors such as higher accessibility to a variety of products, higher flexibility, and expanded reach are major determinants for driving the distributor sales channel segment.

Direct sales channel segment accounted for a significant revenue in the overall aircraft jack market share in 2024.

- In direct sales channel, airplane jacks are sold directly to customers through numerous physical outlets including company outlets among others.

- Moreover, the direct sales channel also consists of online mode, wherein the manufacturers sell jacks through its own company websites.

- Additionally, purchasing jacks from direct sales channel offers numerous benefits including faster response time, higher product quality, higher return on investments, competitive pricing, and others which are key determinants for increasing the purchase of airplane jacks from direct sales channel.

- For instance, FlyTek GSE is an airplane jack manufacturer that offers a broad range of airplane jacks including axle jacks and tripod jacks for direct purchase through the company website.

- Therefore, increasing availability of airplane jacks in direct sales channels are driving the aircraft jack market trends.

Distributor sales segment is anticipated to register a substantial CAGR growth during the forecast period.

- The distributor sales channel involves indirect distribution of airplane jacks, wherein the jacks are purchased from several regional distributors operating in multiple regions worldwide.

- Moreover, distributor sales channel provide several benefits including increased market reach, reduced capital expenditure, increased cost efficiency, and others. The above benefits of distributor sales channel are further increasing its utilization for purchase of airplane jacks.

- For instance, RHE Southern Limited, Worlifts Limited, and LAS Aerospace Ltd are few of the distributors of aircraft jacks.

- Hence, the increasing availability of airplane jacks in distributor sales channel is anticipated to boost the market during the forecast period.

By End-Use:

Based on the end-use, the market is segmented into commercial aircraft, military aircraft, and others.

Trends in the end-use:

- Factors including rising air travel trend, growing commercial flight activities, and increasing production of commercial aircrafts are key factors fueling the commercial segment.

- Rising technological advancements in air defense systems, increasing government investments in airborne defense platform, and growing need for advanced military aircraft for enhancement of aerial defense capabilities are primary trends driving the military & defense segment.

Commercial segment accounted for the largest revenue share in the total market share in 2024.

- This dominance is attributed to the rising adoption of airplane jacks for supporting various sub-component assembly, inspection, along with maintenance, repair, and operation (MRO) activities for commercial aircraft.

- Moreover, commercial airlines perform routine maintenance checks, wherein these jacks are typically used to lift the aircraft for inspection and maintenance of several components such as landing gear, engine mounts, and others.

- For instance, Airbus delivered 14,950 commercial aircrafts as of September 2023, which includes 11,370 single-aisle aircrafts and 3,580 wide body aircrafts.

- According to the analysis, the increasing production of commercial aircraft is driving the market.

Military & defense segment is anticipated to register a substantial CAGR during the forecast period.

- Military & defense aircraft undergo rigorous inspection protocols to ensure they are combat-ready. Airplane jacks are primarily used during these inspections to access critical components quickly and safely.

- Moreover, hydraulic and pneumatic jacks are often employed for pre-flight inspections and checks to ensure that aircraft systems are operational, particularly in weapon systems and landing gear of the defense aircraft.

- For instance, in 2023, Shaanxi Aircraft Corporation introduced its new and enhanced special mission aircraft that is optimized for airborne early warning and control operation.

- Therefore, the increasing development of military aircraft is expected to drive the demand for airplane jacks during inspection and MRO activities, in turn propelling the market during the forecast period.

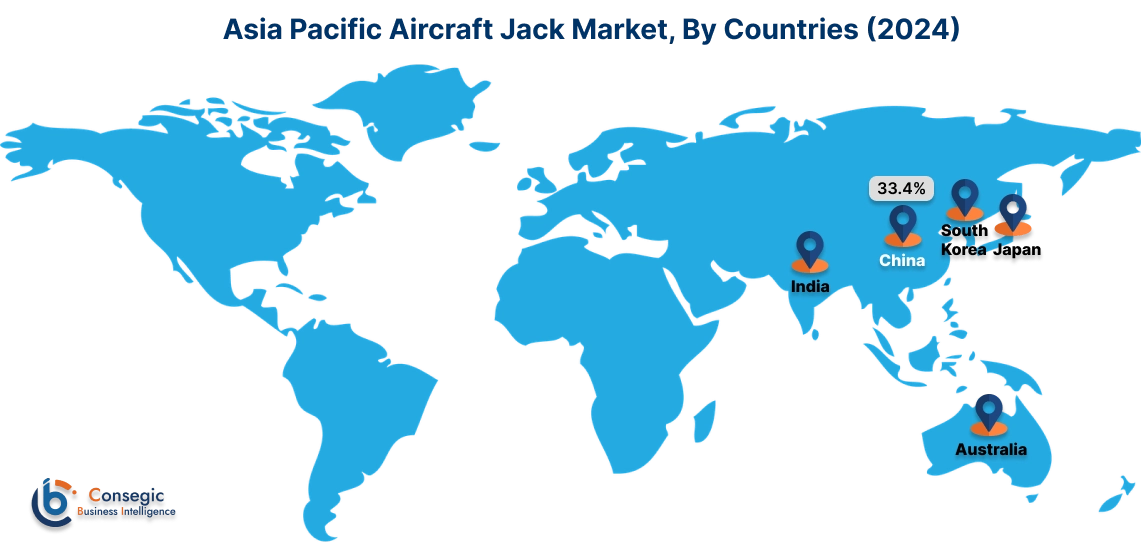

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 297.28 Million in 2024. Moreover, it is projected to grow by USD 304.75 Million in 2025 and reach over USD 398.15 Million by 2032. Out of this, China accounted for the maximum revenue share of 33.4%. As per the aircraft jack market analysis, the adoption of airplane jacks in the Asia-Pacific region is primarily driven by the increasing production from aerospace & defense industry and rising investments in aircraft manufacturing facilities among others. Additionally, the rising expenditure on aircraft MRO (maintenance, repair, and operation) activities further accelerating the aircraft jack market expansion.

- For instance, according to the International Air Transport Association, the total spending on commercial aircraft MRO activities in Asia-Pacific region was valued at approximately USD 19 billion in 2023, and it is projected to reach up to USD 27 billion by 2033. The above factors are further driving the adoption of airplane jacks to ensure safe and effective serviceability while providing access to various components of the aircraft, in turn propelling the market in the Asia-Pacific region.

North America is estimated to reach over USD 505.80 Million by 2032 from a value of USD 391.55 Million in 2024 and is projected to grow by USD 400.17 Million in 2025.

In North America, the growth of aircraft jack industry is driven by the growing commercial aviation and defense sectors. Similarly, the rising development of aircraft production facilities are contributing to the aircraft jack market demand.

- For instance, in October 2023, BETA Technologies launched its first electric aircraft manufacturing plant in Vermont, United States. The manufacturing facility has a total production capacity of 300 aircraft per year. The rising development of aircraft manufacturing facilities is increasing the demand for airplane jacks for ensuring that the assembly, inspection, and testing of aircraft components are conducted safely and efficiently. The above factors are projected to drive the aircraft jack market trends in North America during the forecast period.

The regional analysis depicts that rising production of military and commercial aircrafts along with increasing need for aircraft inspection, maintenance, and repair services are driving the aircraft jack market demand in Europe. Furthermore, as per the market analysis, the market demand in Latin America, Middle East, and African regions is expected to grow at a considerable rate due to factors such as growing aerospace & defense industry and increasing investments in aircraft MRO activities among others.

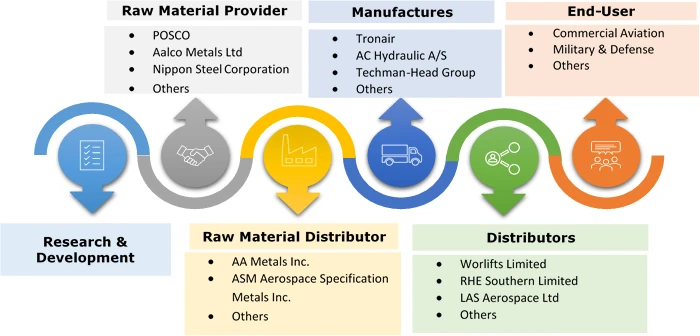

Top Key Players and Market Share Insights:

The global aircraft jack market is highly competitive with major players providing services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the aircraft jack market. Key players in the aircraft jack industry include-

- Tronair (U.S.)

- AC Hydraulic A/S (Denmark)

- Techman-Head Group (France)

- Solair Group LLC (U.S.)

- Langa Industrial SA (Spain)

- Hydro Systems GmbH & Co. KG (Germany)

- Makro Aero (Turkey)

- GSE Composystem (Spain)

- FlyTek GSE (U.S.)

- JMS AG Jet (Germany)

Recent Industry Developments :

Partnerships & Collaborations:

- In April 2023, Hydro Systems KG partnered with Allen Engineering Corp. for the production of the new RA axle-jacks. The RA axle jack features a unique design and high versatility, which makes it ideal for utilization in both narrow and wide-body aircraft.

Aircraft Jack Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2032 |

| Market Size in 2032 | USD 1,468.63 Million |

| CAGR (2025-2032) | 3.6% |

| By Type |

|

| By Aircraft Type |

|

| By Sales Channel |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the aircraft jack market? +

The aircraft jack market was valued at USD 1,131.66 Million in 2024 and is projected to grow to USD 1,468.63 Million by 2032.

Which is the fastest-growing region in the aircraft jack market? +

Asia-Pacific is the region experiencing the most rapid growth in the aircraft jack market.

What specific segmentation details are covered in the aircraft jacks report? +

The aircraft jacks report includes specific segmentation details for type, aircraft type, sales channel, end-use, and region.

Who are the major players in the aircraft jack market? +

The key participants in the aircraft jack market are Tronair (U.S.), AC Hydraulic A/S (Denmark), Techman-Head Group (France), Solair Group LLC (U.S.), Langa Industrial SA (Spain), Hydro Systems GmbH & Co. KG (Germany), Makro Aero (Turkey), GSE Composystem (Spain), FlyTek GSE (U.S.), and JMS AG Jet (Germany).