- Summary

- Table Of Content

- Methodology

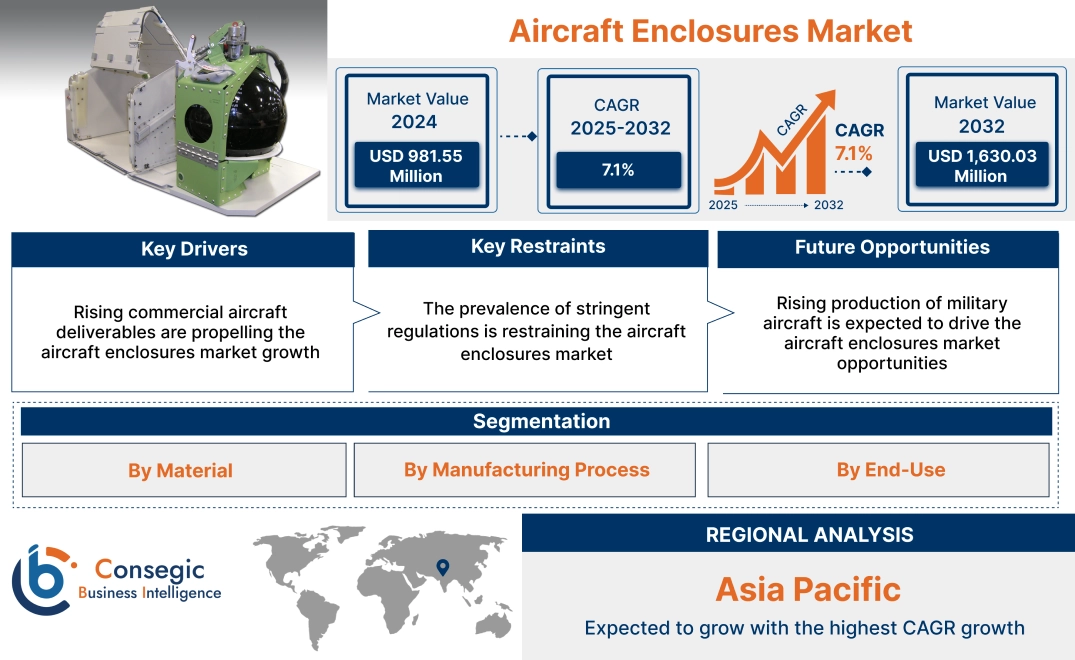

Aircraft Enclosures Market Size:

Aircraft Enclosures Market size is estimated to reach over USD 1,630.03 Million by 2032 from a value of USD 981.55 Million in 2024 and is projected to grow by USD 1,028.72 Million in 2025, growing at a CAGR of 7.1% from 2025 to 2032.

Aircraft Enclosures Market Scope & Overview:

Aircraft enclosures (AE) refer to specialized protective housings that are designed to safeguard the electronic systems and components within an aircraft. These enclosures are engineered to withstand harsh environments, including extreme temperatures, vibration, moisture, electromagnetic interference (EMI), and other environmental factors. Moreover, AE offers several benefits such as improved structural integrity, EMI and RFI shielding, enhanced protection against environmental factors, and others.

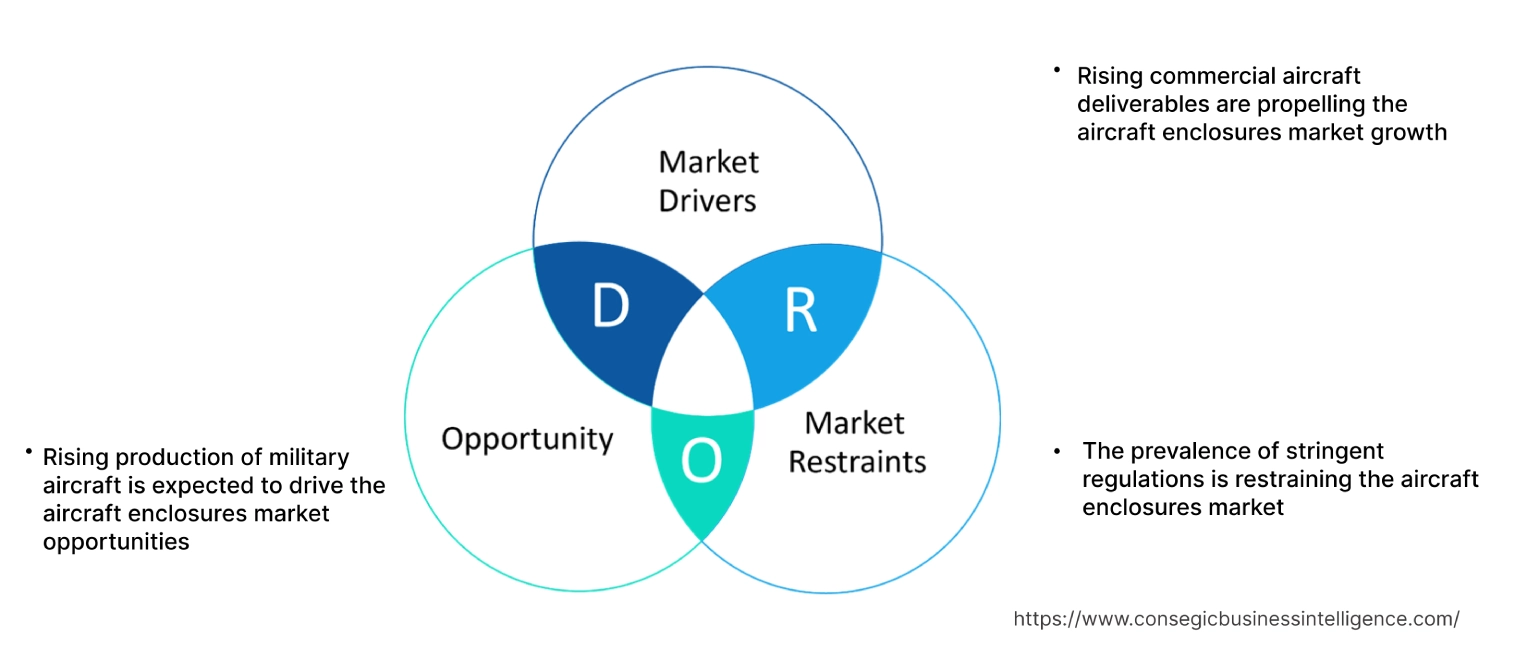

Key Drivers:

Rising commercial aircraft deliverables are propelling the aircraft enclosures market growth

Aircraft enclosures play a crucial role in the commercial aviation sector. In commercial aircraft, enclosures play a critical role in the protection and functionality of various aircraft systems. Moreover, these enclosures are primarily used in commercial aircraft for facilitating improved protection of several aircraft systems including flight control systems, navigation and communication systems, in-flight entertainment systems, power distribution units, and other related aircraft instruments.

- For instance, Airbus, a European aircraft manufacturer, delivered 735 commercial aircraft in 2022, depicting an increase of approximately 11% in comparison to 661 deliverables in 2022.

Therefore, the rising development of commercial aircraft is increasing the adoption of enclosures for facilitating improved protection of several aircraft systems including flight control systems, navigation and communication systems, in-flight entertainment systems, and others, in turn proliferating the aircraft enclosures market size.

Key Restraints:

The prevalence of stringent regulations is restraining the aircraft enclosures market

The manufacturers of aircraft enclosure have to comply with numerous stringent standards such as ISO (International Organization for Standardization) standards - ISO 9001, AS9100, NADCAP, and others, which is a primary factor constraining the market growth.

For instance, the ISO 9001 standard specifies particular requirements for a quality management system. Aircraft enclosure manufacturers must comply with the ISO standard to demonstrate the ability to consistently provide products and services that meet regulatory and customer requirements. Additionally, AS9100 is an aerospace standard that is designed for achieving high quality in the aviation, space, and defense sectors. AS9100 governs any design and manufacturing of aerospace products, maintenance, along with aerospace product distribution.

Therefore, the prevalence of the aforementioned regulations and standards associated with manufacturing aircraft enclosures is hindering the aircraft enclosures market expansion.

Future Opportunities :

Rising production of military aircraft is expected to drive the aircraft enclosures market opportunities

Aircraft enclosures are often used in military aircraft to ensure improved reliability, safety, and efficiency of military aircraft systems. Their robust design enables increased protection of vital electronic components in a demanding operational environment, which further increases the overall reliability and safety of military aircraft. The enclosures are used in military aircraft for protecting several electronic systems such as avionics systems, communication systems, environmental control systems, and others.

- For instance, Dassault Aviation, a French manufacturer of business jets and military aircraft, launched its new Rafale fighter aircraft in December 2022. The military aircraft was designed for deployment in the Directorate General of Armaments, a France-based military procurement agency.

Hence, as per the analysis, the rising production of military aircraft is projected to increase the demand for AE for protection of vital electronic components used in military aircraft, thereby, driving the aircraft enclosures market opportunities during the forecast period.

Aircraft Enclosures Market Segmental Analysis :

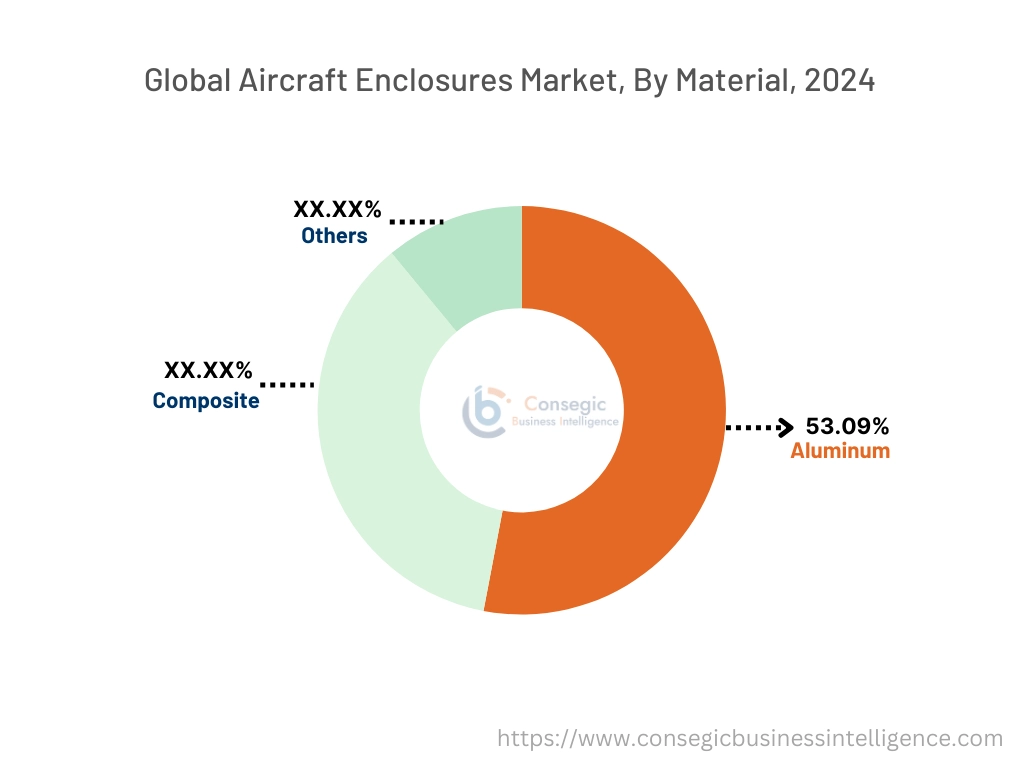

By Material:

Based on machine type, the market is segmented into aluminum, composite, and others.

Trends in the material:

- Increasing adoption of aluminum enclosures due to its several benefits including lightweight, durability, corrosion resistance, and others.

- There is a rising trend towards the utilization of composite enclosures, attributed to its high strength-to-weight ratio and improved performance.

The aluminum segment accounted for the largest revenue share of 53.09% in the total aircraft enclosures market share in 2024.

- Aluminium is among the primary materials used in aircraft enclosures, owing to its lightweight, durability, and ability to withstand heavy use.

- Moreover, aluminum also offers several benefits such as high thermal conductivity, corrosion resistance, excellent thermal and acoustic insulation, weather resistance, and improved fuel efficiency, which are primary determinants for increasing its utilization in airplane enclosures.

- For instance, Churchill Corporation offers a CX series of aluminum enclosures for aircraft applications in its product offerings. The aluminum enclosures feature lightweight and high tolerance, making them suitable for application in aircraft electronics systems.

- According to the aircraft enclosures market analysis, the rising advancements associated with aluminum enclosures for application in aircraft are driving the aircraft enclosures market growth.

The composite segment is anticipated to register the fastest CAGR during the forecast period.

- Composite materials are composed of two or more constituent materials that possess different chemical or physical properties. These constituents remain separate and distinct within the finished structure, resulting in a material that possesses unique characteristics that are favorable for specific applications.

- Moreover, composite enclosures offer a range of benefits including lightweight, high strength-to-weight ratio, increased corrosion resistance, improved performance, and others.

- For instance, TE Connectivity offers composite enclosures for aircraft applications in its product portfolio. The composite enclosures feature a rugged and corrosion-resistant design and are up to 50% lighter in weight as compared to aluminum.

- Therefore, the increasing advancements related to composite enclosures are anticipated to boost the aircraft enclosures market size during the forecast period.

By Manufacturing Process:

Based on the manufacturing process, the market is segmented into CNC machining, injection molding, metal stamping, and others.

Trends in the manufacturing process:

- There is an increasing trend towards the adoption of a metal stamping process for manufacturing enclosures for sensitive avionics systems.

- Rising adoption of injection molding technique for manufacturing enclosures for aircraft electronic systems due to its lower cost and consistency.

The metal stamping segment accounted for the largest revenue in the overall aircraft enclosures market share in 2024, and it is anticipated to register a significant CAGR growth during the forecast period.

- Metal stamping refers to a manufacturing process that involves the creation of parts by deforming or cutting sheet metal by using a die and press. In this process, metal sheets are placed in a stamping press, which applies force to shape the metal into the desired form according to the die's specifications.

- Moreover, the metal stamping method offers numerous benefits including high production rates, improved precision, increased versatility for a wide range of metals, and others, which are primary aspects for driving its utilization in the manufacturing of enclosures for aircraft applications.

- For instance, Hudson Technologies offers custom metal stamping solutions in its portfolio. The company offers custom metal stamping solutions for fabricating a wide range of aerospace components including military aircraft housings and enclosures.

- Therefore, the rising developments associated with the utilization of metal stamping methods for manufacturing aerospace enclosures are driving the aircraft enclosures market trends.

By End-Use:

Based on the end-use, the market is segmented into commercial aircraft, military aircraft, and others.

Trends in the end-use:

- Factors including rising air travel trends, growing commercial flight activities, and increasing production of commercial aircraft are key factors fueling the growth of the commercial aircraft segment.

- Rising technological advancements in air defense systems, increasing government investments in airborne defense platforms, and the growing need for advanced military aircraft for the enhancement of aerial defense capabilities are primary trends driving the military aircraft segment.

The commercial aircraft segment accounted for the largest revenue share in the total market share in 2024.

- This dominance is attributed to the rising adoption of aerospace enclosures in commercial aircraft to increase the durability, reliability, and safety of advanced electronics systems used in commercial aircraft.

- Moreover, these enclosures are primarily used in commercial aircraft for facilitating improved protection of several aircraft systems including flight control systems, navigation and communication systems, in-flight entertainment systems, power distribution units, and other related aircraft instruments.

- For instance, Airbus delivered 14,950 commercial aircraft as of September 2023, which includes 11,370 single-aisle aircraft and 3,580 wide-body aircraft.

- According to the analysis, the rising production of commercial aircraft is driving the aircraft enclosures market.

The military aircraft segment is anticipated to register a significant CAGR during the forecast period.

- Aircraft enclosures are often used in military aircraft to ensure improved reliability, safety, and efficiency of military aircraft systems.

- Their robust design enables increased protection of vital electronic components in a demanding operational environment, which further increases the overall reliability and safety of military aircraft.

- For instance, in 2023, Shaanxi Aircraft Corporation introduced its new and enhanced special mission aircraft that is optimized for airborne early warning and control operation.

- Therefore, the increasing development of military aircraft is expected to drive the demand for aerospace enclosures for the protection of vital electronic components used in military aircraft, in turn propelling the market during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

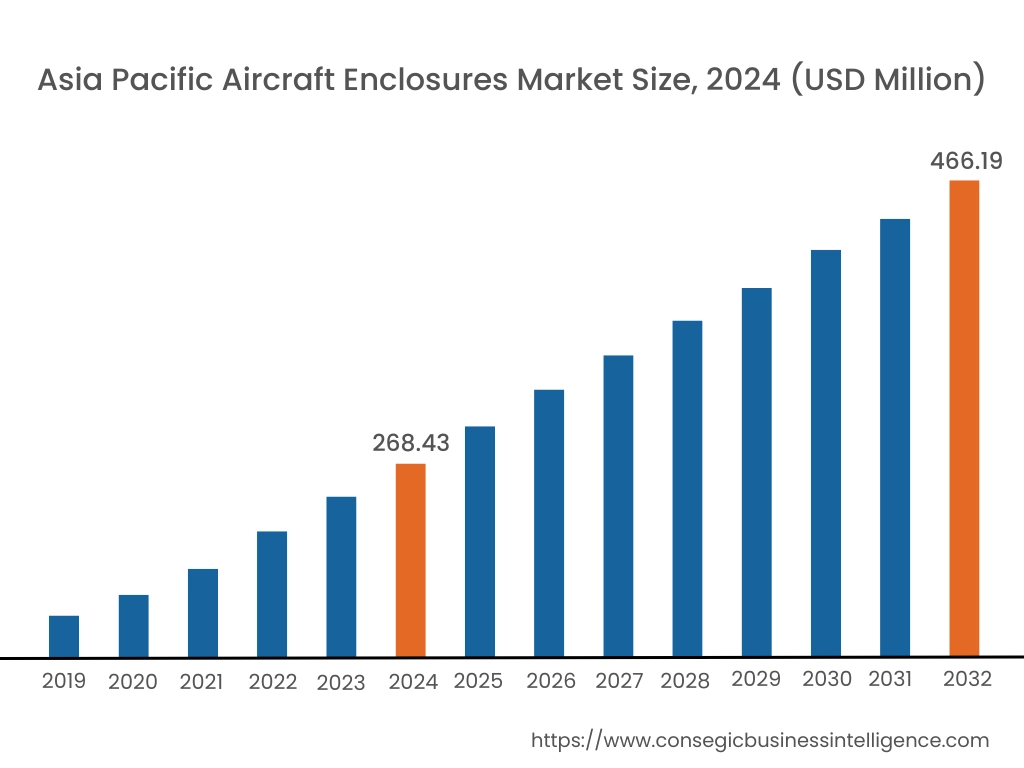

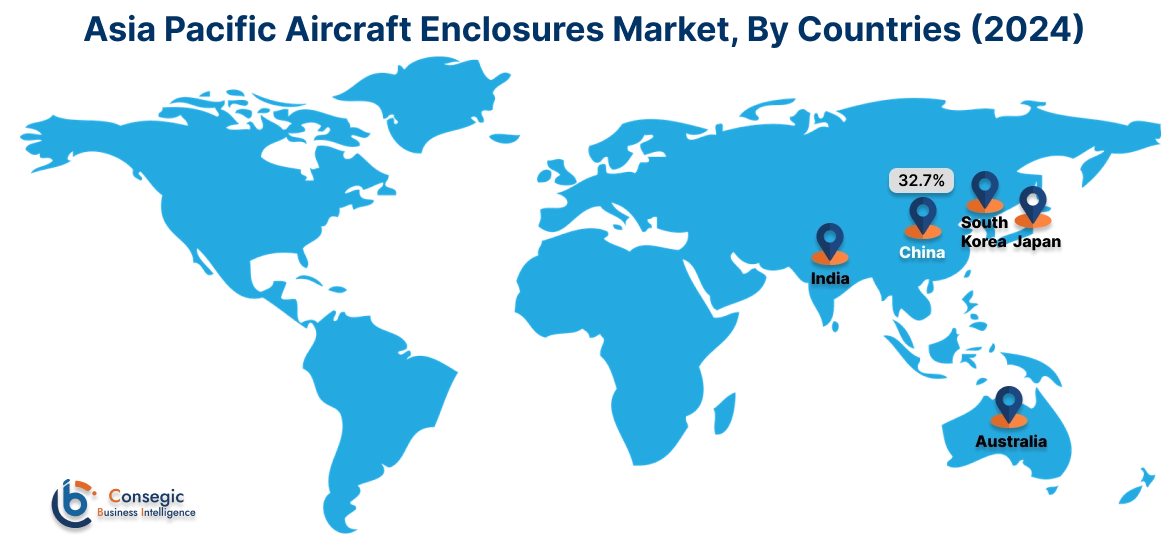

Asia Pacific region was valued at USD 268.43 Million in 2024. Moreover, it is projected to grow by USD 282.41 Million in 2025 and reach over USD 466.19 Million by 2032. Out of this, China accounted for the maximum revenue share of 32.7%. As per the aircraft enclosures market analysis, the adoption of aerospace enclosures in the Asia-Pacific region is primarily driven by the increasing production from the aerospace & defense industry and rising investments in military aircraft among others. Additionally, the rising aircraft production is further accelerating the aircraft enclosures market expansion.

- For instance, in October 2022, Tata Advanced Systems Limited launched its new C-295 transport aircraft manufacturing facility in Gujarat, India in collaboration with Airbus. The manufacturing facility is responsible for the delivery of C-295 transport aircraft to the Indian Air Force. The above factors are driving the adoption of aerospace enclosures, in turn propelling the market in the Asia-Pacific region.

North America is estimated to reach over USD 538.40 Million by 2032 from a value of USD 329.15 Million in 2024 and is projected to grow by USD 344.54 Million in 2025. In North America, the growth of the aircraft enclosures industry is driven by the growing commercial aviation and defense sectors. Similarly, the rising development of commercial aircraft is contributing to the aircraft enclosures market demand.

- For instance, Boeing, a U.S.-based aerospace company, delivered approximately 136 commercial aircraft during the second quarter of 2023, depicting an increase of 4.6% in comparison to 130 commercial aircraft deliverables during the first quarter of 2023. The rising commercial aircraft deliverables are projected to drive the aircraft enclosures market trends in North America during the forecast period.

The regional analysis depicts that the rising production of military and commercial aircraft is driving the aircraft enclosures market demand in Europe. Furthermore, as per the market analysis, the market demand in Latin America, the Middle East, and African regions is expected to grow at a considerable rate due to factors such as the growing aerospace & defense industry and increasing investments in aircraft production among others.

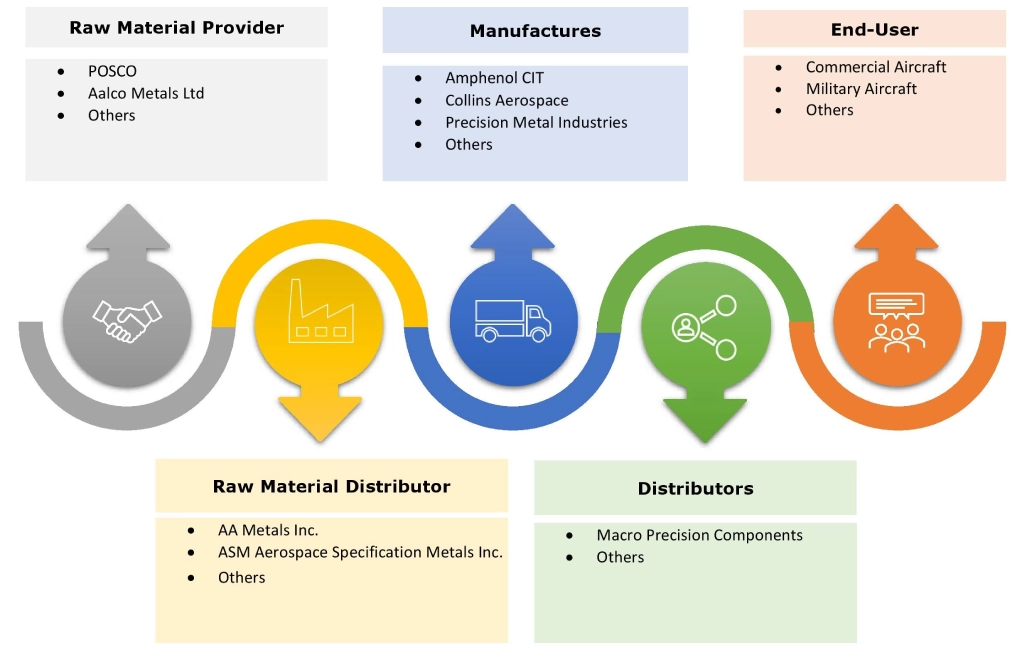

Top Key Players and Market Share Insights:

The global aircraft enclosures market is highly competitive with major players providing services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the aircraft enclosures market. Key players in the aircraft enclosures industry include-

- Amphenol CIT (U.S)

- Collins Aerospace (U.S.)

- H. NUNN ASSOCIATES (U.S.)

- MSP Manufacturing Inc. (U.S.)

- ProtoSpace Mfg (U.S.)

- Precision Metal Industries (U.S.)

- Churchill Corporation (U.S.)

- Ducommun Incorporated (U.S.)

- Héroux-Devtek (Canada)

- TE Connectivity (Ireland)

Aircraft Enclosures Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1,630.03 Million |

| CAGR (2025-2032) | 7.1% |

| By Material |

|

| By Manufacturing Process |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the aircraft enclosures market? +

The aircraft enclosures market was valued at USD 981.55 Million in 2024 and is projected to grow to USD 1,630.03 Million by 2032.

Which is the fastest-growing region in the aircraft enclosures market? +

Asia-Pacific is the region experiencing the most rapid growth in the aircraft enclosures market.

What specific segmentation details are covered in the aircraft enclosures report? +

The aircraft enclosures report includes specific segmentation details for system material, manufacturing process, end-use, and region.

Who are the major players in the aircraft enclosures market? +

The key participants in the aircraft enclosures market are Amphenol CIT (U.S), Collins Aerospace (U.S.), Precision Metal Industries (U.S.), Churchill Corporation (U.S.), Ducommun Incorporated (U.S.), Héroux-Devtek (Canada), TE Connectivity (Ireland), J.H. NUNN ASSOCIATES (U.S.), MSP Manufacturing Inc. (U.S.), and ProtoSpace Mfg (U.S.).