- Summary

- Table Of Content

- Methodology

Aircraft EMI Shielding Market Size:

Aircraft EMI Shielding Market size is estimated to reach over USD 1,519.43 Million by 2031 from a value of USD 1,060.35 Million in 2023 and is projected to grow by USD 1,090.23 Million in 2024, growing at a CAGR of 4.60% from 2024 to 2031.

Aircraft EMI Shielding Market Scope & Overview:

The aircraft EMI (Electromagnetic Interference) protects aircraft electronic systems from electromagnetic interference, ensuring operational safety and reliability. EMI shielding is essential for maintaining the functionality of avionics, communication systems, and navigation equipment in the highly dynamic and sensitive aerospace environment. Key characteristics of aircraft EMI shielding include high conductivity, durability, lightweight construction, and resistance to harsh environmental conditions. The benefits include enhanced system performance, reduced signal disruptions, and compliance with stringent aerospace safety standards. Applications span shielding for avionics enclosures, cables, airframes, and connectors. End-users include aircraft manufacturers, defense organizations, and maintenance, repair, and overhaul (MRO) providers, driven by increasing adoption of advanced avionics systems, rising demand for lightweight shielding solutions, and stringent regulatory requirements for electromagnetic compatibility (EMC) in the aerospace sector.

Key Drivers:

Increasing Adoption of Advanced Avionics Systems Drives the Market

The aviation sector is witnessing a significant shift toward advanced avionics systems, which include navigation, communication, and flight control technologies. These systems are essential for modern aircraft operations, providing real-time data and ensuring precision in complex flight scenarios. However, their heightened sensitivity to electromagnetic interference (EMI) makes robust shielding solutions a critical requirement. Without effective EMI shielding, the performance of these systems can be compromised, potentially impacting safety and operational efficiency.

Trends in digitalization and the integration of cutting-edge electronics in next-generation aircraft further underscore the importance of EMI shielding. As avionics systems become more interconnected and sophisticated, the need for shielding solutions that ensure uninterrupted performance has become integral to aircraft design. Analysis highlights the role of advanced EMI shielding in maintaining system integrity and meeting the rigorous safety standards of the aerospace sector.

Key Restraints :

Stringent Certification and Regulatory Requirements Limits the Market

The aerospace industry is governed by stringent certification and regulatory requirements that mandate the safety and reliability of EMI shielding solutions. These standards are in place to ensure that all materials and components meet the necessary electromagnetic compatibility (EMC) benchmarks. Achieving compliance often requires extensive testing, validation, and documentation, which can increase costs and extend development timelines for manufacturers.

Additionally, variations in certification processes across regions further complicate the market landscape, creating barriers for companies operating on a global scale. While these regulations are essential for safety, they also present challenges for emerging technologies and smaller manufacturers aiming to enter the market. Overcoming these hurdles requires close collaboration with regulatory bodies and significant investment in research and testing capabilities.

Future Opportunities :

Development of Lightweight and High-Performance EMI Shielding Solutions Opens New Doors

The increasing aircraft EMI shielding market opportunities on lightweight and fuel-efficient aircraft design has created opportunities for innovative EMI shielding solutions. Traditional shielding materials such as metal foils and enclosures add weight, which can impact fuel efficiency and overall aircraft performance. Advancements in materials science, including the development of nanomaterials and conductive polymers, are enabling the creation of lightweight shielding solutions that offer comparable or superior performance.

These high-performance materials are particularly important in aircraft constructed with composite materials, which lack natural EMI shielding properties. By integrating lightweight and adaptable shielding solutions, manufacturers can align with aircraft EMI shielding market trends in modern aerospace engineering, balancing weight reduction with enhanced electromagnetic protection. Analysis suggests that these innovations will play a pivotal role in supporting the next generation of aviation technologies, particularly as electric and hybrid-electric aircraft emerge.

Aircraft EMI Shielding Market Segmental Analysis :

By Type:

Based on type, the market is segmented into Conductive Coatings and Paints, Conductive Tapes and Films, Metal Shielding, Conductive Gaskets, and Others.

Conductive coatings and paints accounted for the largest aircraft EMI shielding market share in 2023.

- These solutions are widely used to protect electronic components and aircraft systems from electromagnetic interference (EMI) and radio frequency interference (RFI).

- Their versatility in application across diverse substrates such as plastics, composites, and metals makes them a preferred choice for lightweight aircraft components.

- Additionally, advancements in nanomaterial-based conductive paints, offering enhanced shielding effectiveness and thermal management, further drive their adoption in the aviation sector.

- Conductive coatings and paints dominate the market due to their high shielding effectiveness and widespread application in lightweight aircraft components.

Conductive gaskets are anticipated to register the fastest CAGR during the forecast period.

- These gaskets ensure reliable EMI shielding while providing environmental sealing in aircraft systems.

- Their use in enclosures, connectors, and panels in high-performance military and commercial aircraft is rising due to increasing aircraft EMI shielding market demand for durable and lightweight shielding solutions.

- The development of advanced elastomeric materials with superior conductivity further supports the trends of this segment.

- Conductive gaskets are poised for rapid growth due to their dual functionality in shielding and sealing applications across advanced aircraft systems.

By Function:

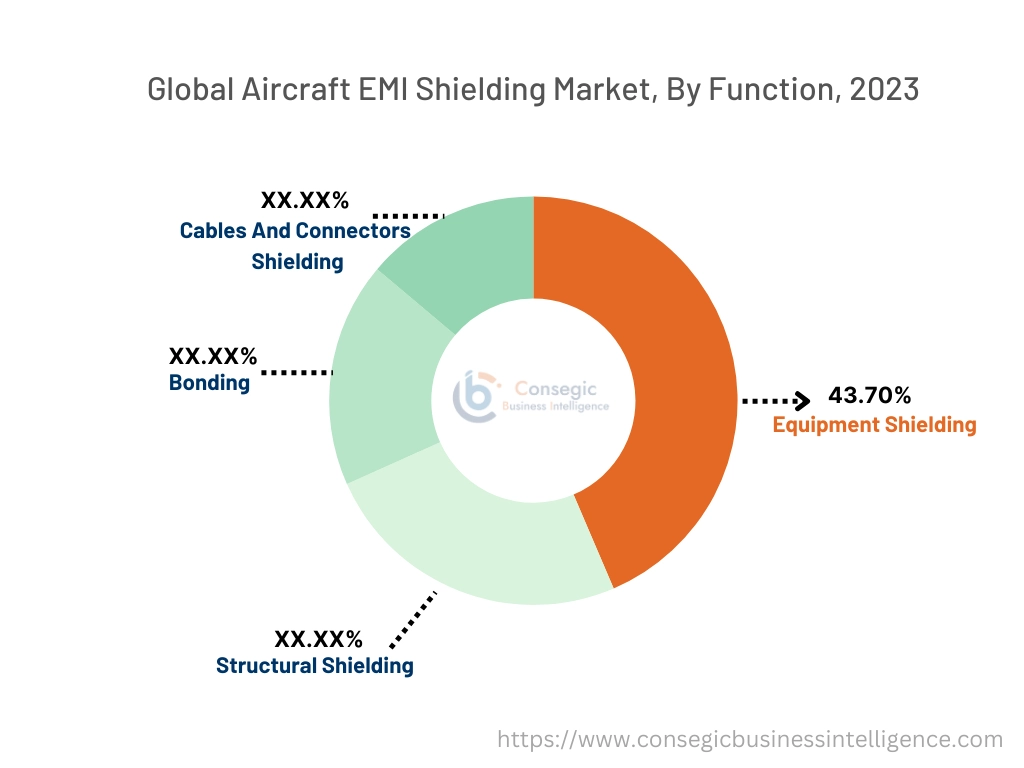

Based on function, the market is segmented into Equipment Shielding, Structural Shielding, Bonding, and Cables and Connectors Shielding.

Equipment shielding held the largest revenue share of 43.70% in 2023.

- This function is critical in protecting sensitive electronic systems and avionics from external electromagnetic interference.

- The increasing reliance on sophisticated avionics and communication systems in modern aircraft amplifies the need for robust equipment shielding solutions.

- Moreover, regulatory compliance requirements for EMI protection in aviation further fuel this segment of aircraft EMI shielding market trends.

- Equipment Shielding leads the function segment due to its vital role in protecting avionics and ensuring uninterrupted aircraft operations.

Cables and connectors shielding is expected to grow at the fastest CAGR during the forecast period.

- Shielding for cables and connectors is crucial in maintaining signal integrity and preventing electromagnetic interference in complex aircraft systems.

- The increasing integration of advanced electronic systems in aircraft, such as radar, navigation, and in-flight entertainment systems, drives the development of superior shielding in cables and connectors.

- Innovations in lightweight and flexible shielding materials are further enhancing this segment's trends.

- Cables and Connectors Shielding is anticipated to grow rapidly, driven by the increasing complexity of electronic systems in modern aircraft.

By Mode of Application:

Based on the mode of application, the market is segmented into Dispensers, Traps, Sprays, and Others.

Sprays held the largest aircraft EMI shielding market share in 2023

- Due to their ease of application and efficiency in achieving uniform coverage over large surfaces.

- These are widely used in applying conductive coatings and paints on aircraft components to achieve EMI shielding.

- Sprays offer superior adhesion and versatility across various substrates, enhancing their adoption in both commercial and military aviation sectors.

- Sprays dominate the trends for a mode of application segment due to their versatility and ease of use in applying conductive coatings on aircraft components.

Dispensers are projected to grow at the fastest CAGR during the forecast period.

- These devices ensure the precise application of conductive adhesives and sealants, reducing material waste and enhancing efficiency in shielding and bonding applications.

- Their growing use in high-precision components of advanced aircraft systems, particularly in OEM manufacturing, is driving segment aircraft EMI shielding market growth.

- Dispensers are expected to grow rapidly, supported by their precision and efficiency in applying conductive materials in advanced aircraft systems.

By Aircraft Type:

Based on aircraft type, the market is segmented into Commercial Aircraft, Military Aircraft, Business Aircraft, and Others.

Commercial Aircraft accounted for the largest revenue share in 2023.

- The increasing global aircraft EMI shielding market for air travel has led to a surge in aircraft production, driving the adoption of EMI shielding solutions to ensure the reliability of avionics systems.

- Conductive coatings, gaskets, and tapes are extensively used to protect communication and navigation systems in commercial aircraft.

- Additionally, regulatory requirements for EMI shielding in passenger aircraft further boost this segment's trends.

- Commercial Aircraft dominate the market due to rising production rates and the critical need for reliable EMI shielding in avionics systems.

Military Aircraft are expected to register the fastest CAGR during the forecast period.

- The growing focus on advanced military aviation technologies, including stealth capabilities, sophisticated radar systems, and secure communication, drives the trends for high-performance EMI shielding solutions.

- The use of lightweight conductive materials in military aircraft to enhance performance while maintaining durability further accelerates the surge in this segment.

- Military Aircraft are projected to grow rapidly, driven by advancements in defense aviation technologies and increasing adoption of high-performance EMI shielding solutions.

By End-User Industry:

Based on end-use, the market is segmented into OEMs (Original Equipment Manufacturers) and Aftermarket.

OEMs held the largest market share of the total aircraft EMI shielding market share in 2023.

- These manufacturers are the primary adopters of EMI shielding solutions, integrating them into aircraft during production.

- The increasing production of next-generation aircraft with advanced electronic systems requires comprehensive shielding solutions to ensure operational efficiency and compliance with aviation safety standards.

- OEMs benefit from strong partnerships with material suppliers to integrate advanced shielding technologies into aircraft designs.

- OEMs lead the market due to their role in integrating advanced EMI shielding solutions during aircraft production.

The Aftermarket segment is expected to grow at the fastest CAGR during the forecast period.

- The need for maintenance, repair, and replacement of shielding materials in aging aircraft drives demand in this segment.

- Additionally, the increasing retrofitting of advanced shielding solutions in older aircraft to meet modern operational standards further supports aftermarket growth.

- The Aftermarket is anticipated to grow rapidly, driven by rising maintenance needs and retrofitting of shielding solutions in aging aircraft fleets.

Regional Analysis:

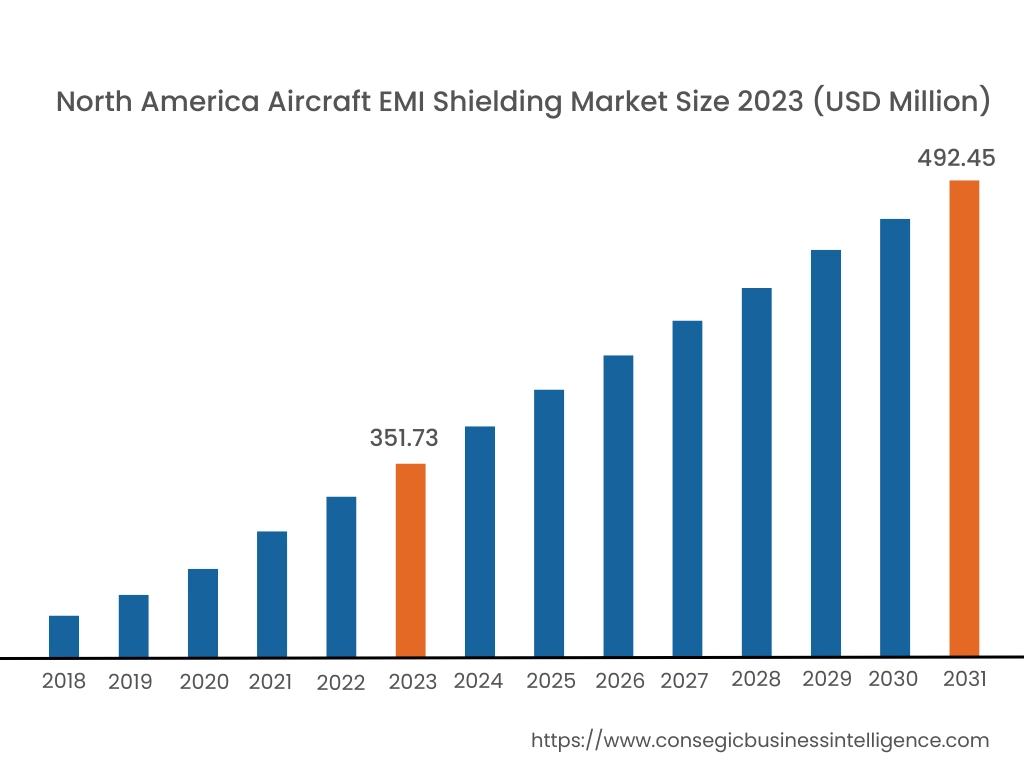

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 351.73 Million and is expected to reach USD 492.45 Million in 2031. In North America, the U.S. accounted for the highest share of 73.70% during the base year of 2023. North America holds a significant stake in the aircraft EMI shielding market analysis, driven by the presence of leading aircraft manufacturers and a strong defense aviation sector. The U.S. leads the region, with extensive adoption of EMI shielding materials in military and commercial aircraft to ensure the safety and reliability of electronic systems. The region benefits from high R&D investments in advanced shielding technologies to support next-generation aircraft and unmanned aerial vehicles (UAVs). Canada contributes through its growing aerospace sector, focusing on lightweight EMI shielding solutions for regional and commercial aircraft. However, rising costs of raw materials and stringent regulations may pose challenges.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.0% over the forecast period. Asia-Pacific is the fastest-growing region in the aircraft EMI shielding market analysis, fueled by increasing air travel demand, rising defense budgets, and expanding aerospace manufacturing in China, India, and Japan. China leads the region with growing production of military and commercial aircraft, boosting the aircraft EMI shielding market demand for EMI shielding materials in avionics and communication systems. India’s focus on indigenously developed aircraft and defense systems supports the adoption of shielding solutions for mission-critical electronic components. Japan emphasizes advanced EMI shielding technologies for precision and reliability in its aerospace sector. However, challenges such as limited domestic manufacturing of high-end materials and fluctuating raw material prices may hinder market growth.

Europe is a prominent market for aircraft EMI shielding, supported by its advanced aerospace industry and growing focus on reducing electromagnetic interference in avionics. Countries like Germany, France, and the UK are key contributors. Germany, a hub for aircraft component manufacturing, drives the use of EMI shielding in high-performance avionics and electronic systems. France’s emphasis on lightweight shielding solutions aligns with its strong civil aviation sector, led by Airbus. The UK focuses on innovative EMI shielding technologies for military aircraft and UAVs. However, compliance with stringent EU aviation standards and high production costs may impact growth in the region.

The Middle East & Africa regional analysis depicts steady growth in the aircraft EMI shielding market, driven by increasing investments in defense and aviation infrastructure. Countries like Saudi Arabia and the UAE are key contributors, adopting EMI shielding solutions in military and commercial aircraft to support modernization efforts. In Africa, South Africa is an emerging market, leveraging shielding technologies for regional and small commercial aircraft. However, limited local production capabilities and reliance on imports for advanced shielding materials may restrict broader market expansion in the region.

Latin America is an emerging market for aircraft EMI shielding, with Brazil and Mexico leading the region. Brazil’s growing aerospace industry, particularly in the production of regional and executive jets, supports the use of EMI shielding materials in avionics and electronic systems. Mexico’s expanding aerospace manufacturing sector, catering to international aircraft component suppliers, drives demand for shielding solutions to meet global standards. However, economic instability and limited technological infrastructure may pose challenges to the aircraft EMI shielding market expansion in the region.

Top Key Players and Market Share Insights:

The Aircraft EMI Shielding market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global aircraft EMI shielding market. Key players in the aircraft EMI shielding industry include -

- Parker Hannifin Corporation (U.S.)

- PPG Industries, Inc. (U.S.)

- Kitagawa Industries Co., Ltd. (Japan)

- Tech-Etch, Inc. (U.S.)

- L. Gore & Associates, Inc. (U.S.)

- 3M Company (U.S.)

- Laird Performance Materials (U.K.)

- Boyd Corporation (U.S.)

- Henkel AG & Co. KGaA (Germany)

- Hollingsworth & Vose Company (U.S.)

Aircraft EMI Shielding Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 1,519.43 Million |

| CAGR (2024-2031) | 4.60% |

| By Type |

|

| By Function |

|

| By Mode of Application |

|

| By Aircraft Type |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected market size of the Aircraft EMI Shielding Market by 2031? +

Aircraft EMI Shielding Market size is estimated to reach over USD 1,519.43 Million by 2031 from a value of USD 1,060.35 Million in 2023 and is projected to grow by USD 1,090.23 Million in 2024, growing at a CAGR of 4.60% from 2024 to 2031.

What are the primary drivers for the growth of the Aircraft EMI Shielding Market? +

The market growth is driven by the increasing adoption of advanced avionics systems, the rising need for lightweight and high-performance EMI shielding solutions, and stringent regulatory requirements for electromagnetic compatibility (EMC) in aerospace.

What are the main challenges in the Aircraft EMI Shielding Market? +

Stringent certification and regulatory requirements, along with high production costs, are key challenges faced by manufacturers in this market.

What are the key applications of EMI shielding in aircraft? +

Applications include shielding for avionics enclosures, cables, connectors, airframes, and structural components to protect sensitive electronic systems from electromagnetic interference.