- Summary

- Table Of Content

- Methodology

Air Bearings Market Size:

Air Bearings Market Size is estimated to reach over USD 9.11 Billion by 2032 from a value of USD 5.85 Billion in 2024 and is projected to grow by USD 6.14 Billion in 2025, growing at a CAGR of 5.7% from 2025 to 2032.

Air Bearings Market Scope & Overview:

Air bearings are a type of bearing that uses a thin film of pressurized air to support a load between two surfaces, eliminating direct contact and the associated friction and wear. This creates a nearly frictionless environment, enabling extremely precise and smooth movement, often used in high-speed applications or where extreme accuracy is required.

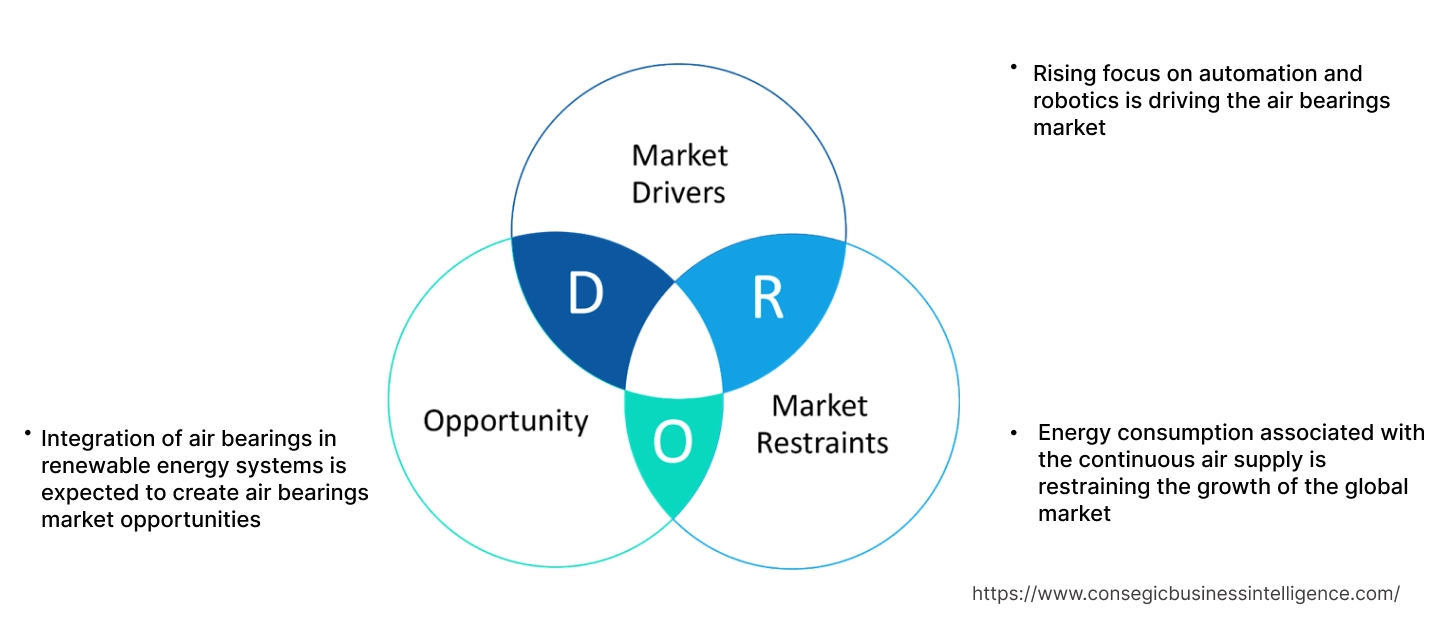

Key Drivers:

Rising focus on automation and robotics is driving the air bearings market

Robotic systems demand extremely precise movements for tasks such as assembly, welding, and painting. Air bearings, with their low friction and high accuracy, enable robots to achieve the necessary precision for these applications. Additionally, many robotic applications require high-speed movements to increase productivity. Air bearings facilitate smooth and fast movements without the risk of wear and tear associated with traditional bearings, suitable for high-speed operations. Also, government funding supports research into new materials, manufacturing processes, and control systems for robotics, leading to advancements in air bearing technology.

- For instance, in 2022, the Japanese government invested over USD 930.5 million in robotics R&D. Furthermore, the Moonshot Research and Development Program, spanning 2020 to 2025, has allocated an additional USD 440 million to robotics-related projects.

Thus, as per the analysis, the rising focus on automation and robotics and significant investment in R&D is driving the air bearings market share.

Key Restraints:

Energy consumption associated with the continuous air supply is restraining the growth of the global market

The energy required to generate and maintain the compressed air supply increases the operational costs of systems utilizing air bearings. Additionally, the increased energy consumption associated with air bearings contributes to higher carbon emissions, raising environmental concerns. As sustainability becomes increasingly important, this factor limits the adoption of air bearings in certain sectors. Moreover, the energy consumption associated with air bearings can make them unsuitable for applications where energy efficiency is critical, such as portable devices or those operating in remote locations with limited power sources.

Thus, as per the market analysis, continuous energy consumption is impeding the global air bearings market growth.

Future Opportunities :

Integration of air bearings in renewable energy systems is expected to create air bearings market opportunities

Air bearings is projected to replace traditional mechanical bearings in wind turbine gearboxes, significantly reducing friction losses. This translates to increased energy output and improved overall efficiency of the wind turbine. Additionally, the frictionless operation of air bearings minimizes wear and tear, leading to increased reliability and reduced maintenance costs for wind turbines. Moreover, government and private companies are heavily investing in wind energy to meet carbon neutrality goals, further creating demand for innovative technologies including air bearings.

- For instance, in December 2024, the Indian government approved a Rs. 7,453 crore Viability Gap Funding (VGF) scheme to kickstart the nation's first offshore wind energy projects. The scheme allocates Rs. 6,853 crore for setting up 1 GW of offshore wind capacity (500 MW each off the coasts of Gujarat and Tamil Nadu) and Rs. 600 crore for upgrading ports to support these projects. This initiative aims to bridge the financial gap for private investors, making these projects economically viable and accelerating India's transition to cleaner energy sources.

Hence, based on the analysis, the increasing government investments in renewable energy projects is expected to present significant air bearings market opportunities.

Air Bearings Market Segmental Analysis :

By Type:

Based on the type, the market is bifurcated into aerostatic bearings and aerodynamic bearings.

Trends in the Type:

- The trend towards miniaturization in various industries is driving the development of smaller and more compact aerostatic bearings.

- Hybrid designs combining features of both aerostatic and aerodynamic bearings are emerging to leverage the advantages of both types.

The aerostatic bearings segment accounted for the largest revenue share in 2024 and are also projected to witness fastest growth

- The inherent characteristics including low friction, high stiffness, and excellent positioning accuracy, make aerostatic bearings ideal for various applications.

- Aerostatic bearings, with their ability to operate at high speeds and with minimal wear and tear, are well-suited for automation and robotics applications.

- Ongoing research and development in materials science, manufacturing techniques, and control systems are leading to continuous improvements in the performance and reliability of aerostatic bearings.

- Thus, as per the analysis, the aforementioned factors are driving the air bearings market size.

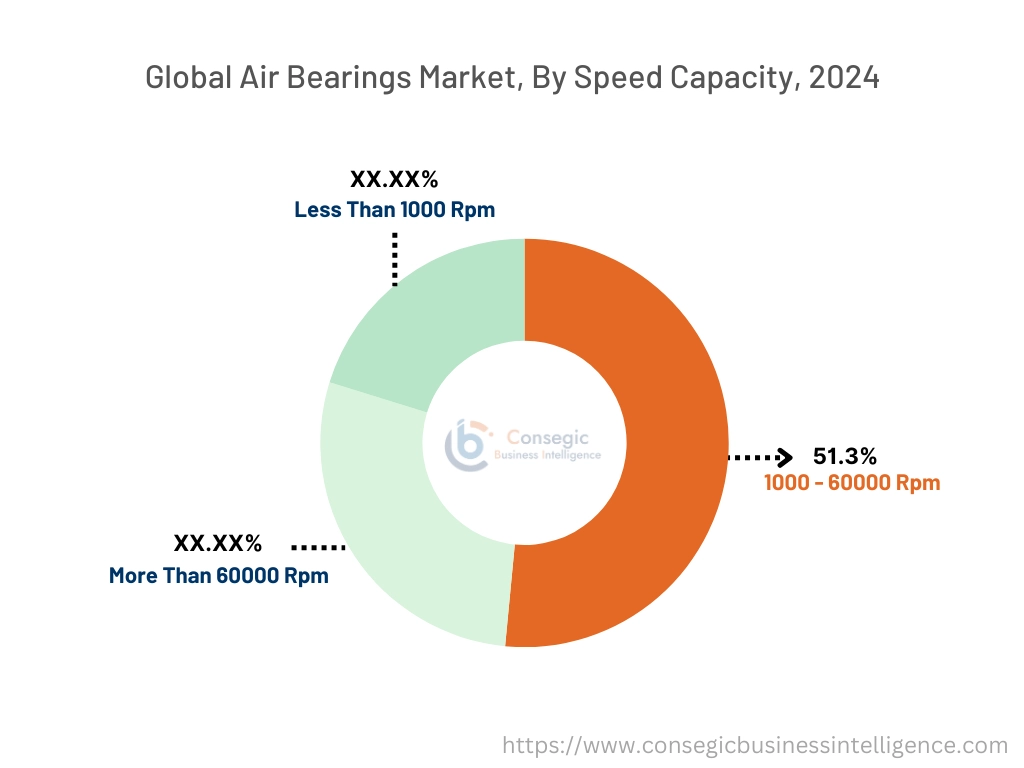

By Speed Capacity:

Based on the speed capacity, the market is segmented into Less than 1000 rpm, 1000 - 60000 rpm, and more than 60000 rpm.

Trends in the Speed Capacity:

- Less than 1000 rpm is seeing growing demand, particularly in high-precision applications such as micromachining, precision positioning, and semiconductor manufacturing.

- Increasing adoption of more than 60000 rpm air bearings in aerospace and other high-tech industries is driving the market trend.

The 1000 - 60000 rpm segment accounted for the largest revenue share of 51.3% in 2024

- This speed range is crucial for a diverse set of applications, including machine tools, robotics, and high-speed spindles, where high-speed machining is critical, driving the air bearings market expansion.

- Development of new materials with improved wear resistance, stiffness, and thermal stability is driving the 1000-60000 rpm air bearings market trend.

- Integration of advanced control systems to optimize bearing performance, improve stability, and enhance overall system efficiency, is boosting the air bearings market expansion.

- For instance, LAB Motion Systems launched RT100AX with 1200 rpm ultra-high speed and compactness are required in one unit. The lightweight and compact build serves as the ideal choice for high-dynamic and accurate positioning tasks in various applications and is ideally suited as final top rotation axis in a multi-axis system.

- Overall, the above-mentioned factors are increasing air bearings market size.

The more than 60000 rpm segment is expected to register the highest CAGR over the forecast period

- Refinement of manufacturing processes like precision machining and additive manufacturing (3D printing) to create more complex and accurate bearing geometries.

- Adoption of advanced manufacturing techniques like laser cutting and micro-machining, which require high-speed and precise motion control.

- These bearings contribute to reduced energy consumption and lower environmental impact due to their low friction characteristics.

- For instance, NAKANISHI INC. offers NRAF-5080 air bearing spindle, which is capable of operating at speeds up to 80,000 RPM. This high-speed capability makes the NRAF-5080 suitable for a wide range of applications, including high-speed machining, micromachining, medical device manufacturing and others.

- Therefore, the above-mentioned factors are driving the air bearings market size.

By Application:

Based on the application, the market is classified into precision metal tools, high-speed machines, coordinate measuring machines, and others.

Trends in the Application:

- The trend is towards higher precision and accuracy in metalworking operations, driven by the need for complex components in industries like aerospace, automotive, and medical devices.

- Air bearings are essential components in advanced CMMs, such as those used in aerospace and automotive industries for inspecting complex parts.

Precision metal tools accounted for the largest revenue share in the year 2024

- The trend towards more complex and sophisticated air bearing designs, such as those with integrated sensors and control systems, requires the use of specialized precision tools. These tools are needed to manufacture intricate geometries and incorporate complex features into the bearing components.

- The trend towards miniaturization in various industries is driving the need for smaller and more compact air bearings.

- Continuous advancements in materials science, manufacturing techniques, and metrology are driving the development of more sophisticated precision tools for the air bearing market.

- Therefore, the aforementioned factors are contributing significantly in accelerating the air bearings market share.

The high-speed machines segment is expected to register the highest CAGR over the forecast period

- The rise of automation in manufacturing processes demands high-speed operations that require precise and reliable components including air bearings.

- Air bearings provide superior performance at high speeds, reducing friction and wear, crucial for maintaining efficiency in high-speed machinery.

- Industries are increasingly focusing on precision and accuracy, particularly in applications such as semiconductor manufacturing, where high-speed machines are essential.

- Therefore, the above-mentioned factors are driving the air bearings market demand in high-speed applications.

By End-Use:

Based on the End-Use, the market is classified into aviation, medical, automotive, semiconductor, wastewater management, and others.

Trends in the End-Use:

- Air bearings are increasingly being used in aircraft engines to reduce friction and wear, leading to improved fuel efficiency and reduced emissions.

- Air bearings can improve the efficiency and performance of electric motors, leading to longer range and faster charging times for EVs.

The semiconductor segment accounted for the largest revenue share in 2024

- Air bearings enable extremely precise movement and positioning of wafers during handling and processing, critical for minimizing contamination and ensuring consistent chip quality.

- Air bearings are used in the stages that hold and move the wafer and the mask during the lithography process, which ensures accurate alignment and pattern transfer onto the wafer.

- Air bearings are essential for enabling advanced packaging technologies like 3D integration and chiplet-based systems, which require high precision and complex movements.

- For instance, according to the Semiconductor Industry Association, the semiconductor sector in the United States experienced significant growth between 2000 and 2020. Sales generated by U.S.-headquartered semiconductor firms more than doubled, increasing from USD 102.0 billion to USD 207.9 billion. This translates to a steady compound annual growth rate of 3.62 percent over the two decades, indicating a consistent expansion of the sector.

- Thus, as per the analysis, the expanding semiconductor sector is driving the air bearings market demand.

The aviation segment is expected to register the highest CAGR over the forecast period

- Air bearings provide the high accuracy and stability required for simulating flight conditions realistically.

- They enable precise movement and positioning of aircraft during maintenance and ground operations.

- Air bearings facilitate the efficient movement and handling of heavy aircraft components during manufacturing and assembly.

- For instance, The Airports Authority of India (AAI) has projected robust growth in the Indian aviation sector over the next five years. They anticipate a sustainable growth rate of 16% for international air travel and a remarkable 20% for domestic flights. This optimistic forecast signals a strong resurgence in air travel demand within India and a promising outlook for the country's aviation industry.

- Therefore, as per analysis, the aforementioned air bearings market trends are expected to continue driving expansion in the coming years.

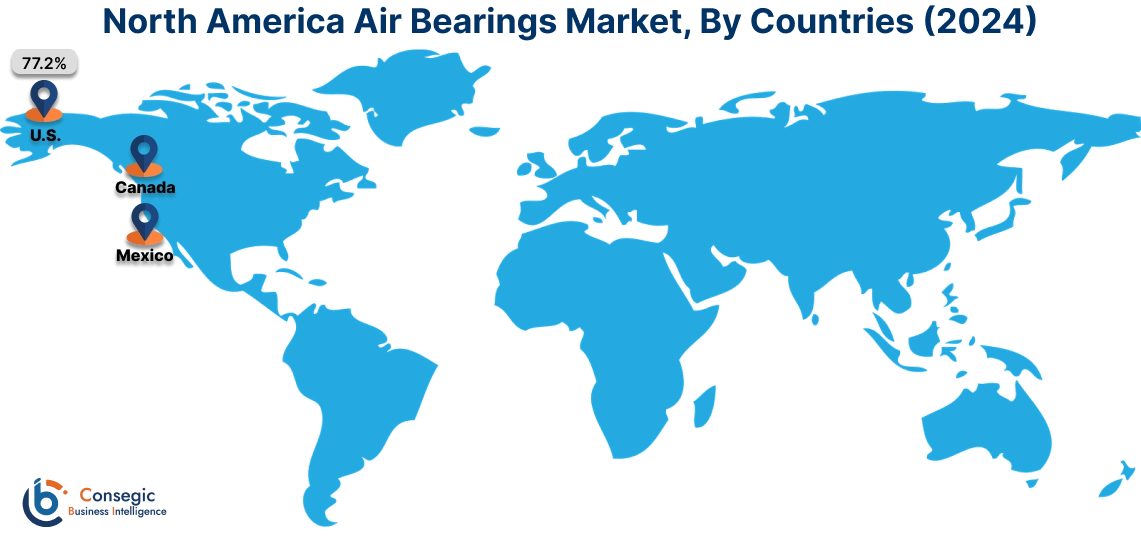

Regional Analysis:

The global air bearings market has been classified by region into North America, Europe, Asia-Pacific, MEA, and Latin America.

North America region was valued at USD 2.37 Billion in 2024. Moreover, it is projected to grow by USD 2.49 Billion in 2025 and reach over USD 3.69 Billion by 2032. Out of these, U.S. accounted for the largest revenue share of 77.2% in 2024.

North America is a global leader in advanced manufacturing, with a strong presence in industries like semiconductors, automotive, and medical devices, all significant users of air bearings. Additionally, a mature and well-developed supply chain for manufacturing and distributing air bearings supports the region's market leadership. Moreover, the region boasts a well-established and technologically advanced aerospace and defense sector, a major consumer of air bearings for aircraft engines and other critical components.

- For instance, according to Aerospace Industries Association (AIA), the U.S. aerospace and defense sector experienced significant growth in 2023, generating over USD 955 billion in sales, a 7.1% increase from the previous year.

Asia Pacific region was valued at USD 1.79 Billion in 2024. Moreover, it is projected to grow by USD 1.88 Billion in 2025 and reach over USD 2.84 Billion by 2032.

The Asia-Pacific region is a major hub for semiconductor manufacturing, and the increasing need for advanced semiconductor technologies is driving the need for high-precision air bearings. In addition, many governments in the region are actively promoting industrial development and technological innovation, which is further fueling the demand for air bearings.

As per the Air Bearings market analysis, European air bearing market is projected to exhibit steady growth, driven by factors such as the region's strong focus on industrial automation, robotics, and advanced manufacturing. Moreover, Latin America region presents a significant emerging market for air bearings owing to the increasing investments in infrastructure and manufacturing. Furthermore, MEA region is expected to witness moderate air bearings market growth due to the expanding oil and gas industry.

Top Key Players and Market Share Insights:

The market is highly competitive with major players providing Air Bearings solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the Air Bearings industry include-

- Air Bearings Ltd. (The U.K.)

- APG-Neuros (Canada)

- Bladon Jets (The U.K.)

- Capstone Turbine Corporation (The U.S.)

- Hovair Systems Inc. (The U.S.)

- IBS Precision Engineering (The Netherlands)

- Specialty Components Inc. (The U.S.)

- LAB Motion Systems (Belgium)

- Nelson Air Corp (The U.S.)

- New Way Air Bearing (The U.S.)

- OAV Air Bearings (The U.S.)

- PI Nelson Air Corp (The U.S.)

- SKF (Sweden)

- Seagull Solutions Inc. (The U.S.)

Recent Industry Developments :

Partnerships & Collaborations:

- In November2024, SKFv has introduced SKF Infinium, designed for circularity. These bearings utilize advanced Laser Metal Deposition (LMD) technology, enabling them to be repeatedly reclad and reused. This innovative approach not only enhances bearing performance and durability but also significantly advances circularity and additive manufacturing within the industry.

Air Bearings Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 9.11 Billion |

| CAGR (2025-2032) | 5.7% |

| By Type |

|

| By Speed Capacity |

|

| By Application |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Air Bearings market? +

Air Bearings Market Size is estimated to reach over USD 9.11 Billion by 2032 from a value of USD 5.85 Billion in 2024 and is projected to grow by USD 6.14 Billion in 2025, growing at a CAGR of 5.7% from 2025 to 2032.

What specific segmentation details are covered in the Air Bearings report? +

The Air Bearings report includes specific segmentation details for type, speed capacity, application, and end-use and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the Air Bearings market, the aviation is the fastest-growing segment during the forecast period.

Who are the major players in the Air Bearings market? +

The key participants in the Air Bearings Ltd. (The U.K.), APG-Neuros (Canada), Bladon Jets (The U.K.), Capstone Turbine Corporation (The U.S.), Hovair Systems Inc. (The U.S.), IBS Precision Engineering (The Netherlands), LAB Motion Systems (Belgium), Nelson Air Corp (The U.S.), New Way Air Bearing (The U.S.), OAV Air Bearings (The U.S.), PI Nelson Air Corp (The U.S.), Seagull Solutions Inc. (The U.S.), SKF (Sweden), Specialty Components Inc. (The U.S.), and others.