- Summary

- Table Of Content

- Methodology

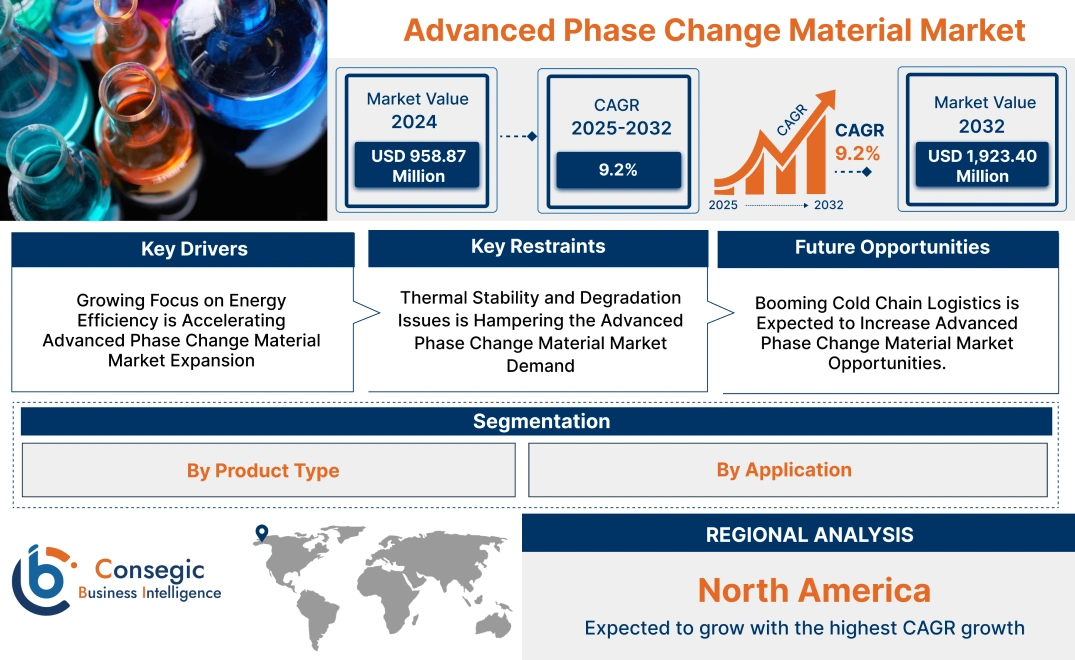

Advanced Phase Change Material Market Size:

Advanced Phase Change Material Market size is growing with a CAGR of 9.2% during the forecast period (2025-2032), and the market is projected to be valued at USD 1,923.40 Million by 2032 from USD 958.87 Million in 2024.

Advanced Phase Change Material Market Scope & Overview:

Advanced phase change materials (PCMs) are specialized substances engineered to undergo reversible phase transitions, most commonly from solid to liquid or vice versa. They possess the ability to store and release large quantities of heat energy during their phase transition. Moreover, PCMs maintain a relatively constant temperature during their phase change, providing precise temperature control in various applications. PCM-integrated building materials regulate indoor temperatures, reducing the need for excessive heating and cooling, leading to significant energy savings. Additionally, PCMs are used as thermal interface materials to dissipate heat generated by electronic components, preventing overheating and improving device performance and reliability. Furthermore, PCM-infused textiles provide thermal comfort by absorbing and releasing heat, keeping the wearer warm in cold conditions and cool in hot environments. Also, PCMs store excess renewable energy, such as solar or wind power, for later use, enhancing the reliability and efficiency of renewable energy systems.

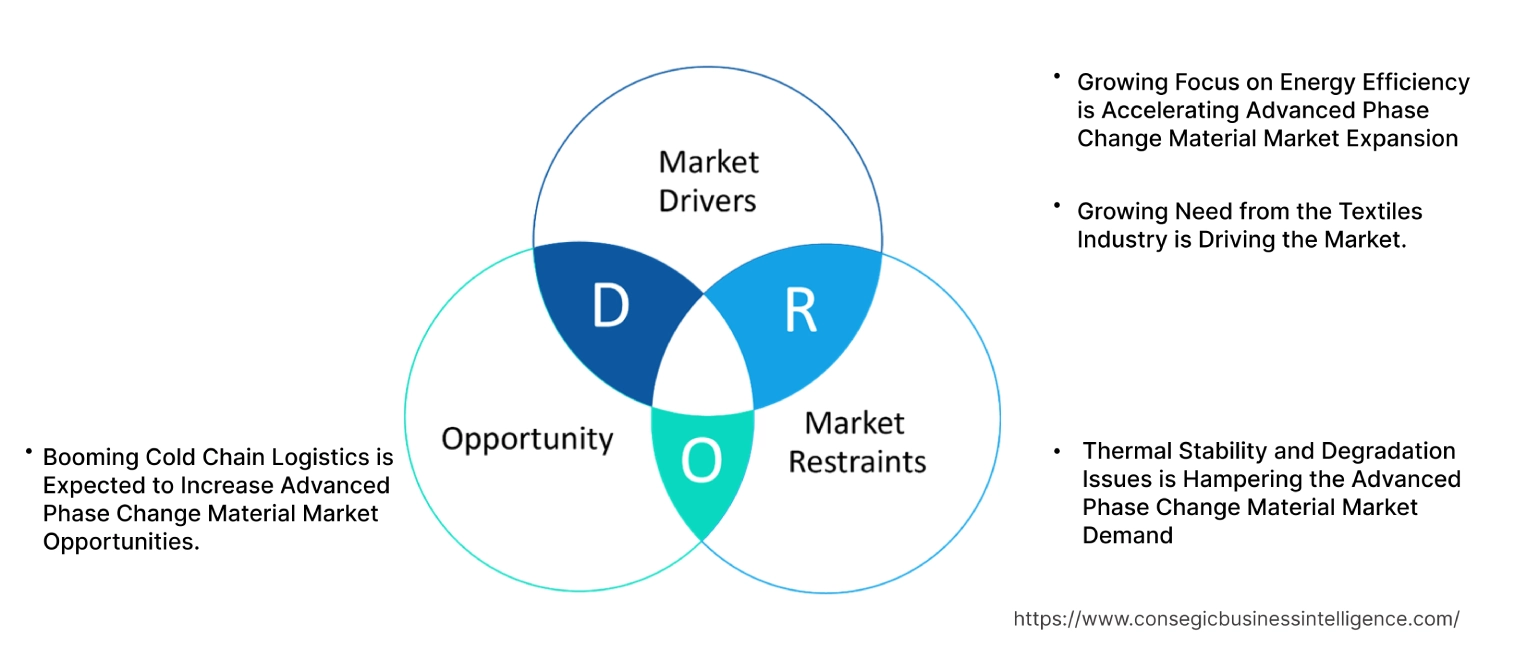

Key Drivers:

Growing Focus on Energy Efficiency is Accelerating Advanced Phase Change Material Market Expansion

PCMs are incorporated into cooling systems to dissipate this heat efficiently, preventing overheating and extending the lifespan of the devices. Moreover, PCMs used to store excess renewable energy help mitigate the intermittent nature of these energy sources and ensure a reliable supply of energy, even during periods of low generation.

Additionally, in buildings, PCM-integrated materials absorb excess heat during the day and release it slowly at night, reducing the need for air conditioning. This not only conserves energy but also lowers energy bills. Governments worldwide are prioritizing energy efficiency initiatives.

- In 2023, the UK government granted USD 1.9 billion to enhance energy efficiency and reduce carbon emissions in both residential and public buildings. This has boosted the need for PCMs as they are integrated into various building materials such as concrete, gypsum wallboard, insulation panels, and even glazing systems to enhance their thermal performance and help in energy efficiency, thus positively influencing advanced phase change material market trends.

Overall, the growing emphasis on energy efficiency, coupled with government initiatives, is significantly boosting the advanced phase change material market expansion.

Growing Need from the Textiles Industry is Driving the Market.

The most common PCM used in textiles is paraffin wax, particularly in the form of long-chain hydrocarbons such as octadecane, hexadecane, and eicosane, which are used in microencapsulated form to be incorporated into fabrics, allowing them to absorb and release heat to regulate body temperature effectively. It is mainly incorporated into athletic wear to manage sweat and maintain optimal body temperature during extreme conditions, such as in sports like ice climbing and motorcycling. Moreover, it is growingly adopted in aerospace due to its multiple benefits.

- According to an article published in Textile Focus, in 2023, PCMs are primarily used in space suits and gloves to regulate temperature. In space suits, PCMs help astronauts stay warm, while in gloves, they protect against extreme temperature fluctuations during spacewalks. Initially developed for astronaut gloves, these microencapsulated PCMs were later adapted for use in glove liners to provide warmth in harsh environments. All these expanded applications have increased the adoption of these PCMs in the textile sector, positively impacting the market.

Overall, the growing adoption in the textiles sector, especially athletic wear and aerospace applications, to regulate temperature and enhance performance in extreme conditions, is accelerating the global advanced phase change material market growth.

Key Restraints:

Thermal Stability and Degradation Issues is Hampering the Advanced Phase Change Material Market Demand

While PCMs offer significant benefits in thermal management, several factors limit their effectiveness and longevity. One of the primary concerns is the degradation of PCM due to thermal cycling. Repeated exposure to temperature fluctuations causes PCM to undergo mechanical stress, leading to cracking, leakage, and reduced thermal conductivity. Moreover, environmental factors also play a crucial role in PCM degradation. Exposure to moisture, dust, or corrosive substances reduces the thermal conductivity and effectiveness of PCM. Furthermore, improper storage and handling lead to contamination and oxidation, further hindering advanced phase change material market trends.

Also, supercooling is the phenomenon that occurs when a PCM remains in a liquid state below its freezing point, leading to a loss of energy storage capacity. Apart from all these factors, there are technical challenges in encapsulating PCMs. Encapsulating materials must be compatible with PCM otherwise it causes leakage and chemical reactions. The encapsulation not maintaining its integrity over multiple phase change cycles causes degradation.

Overall, market analysis shows that the combination of thermal cycling, environmental factors, supercooling, and encapsulation challenges significantly limits the long-term effectiveness and reliability of PCM, hampering the advanced phase change material market demand.

Future Opportunities :

Booming Cold Chain Logistics is Expected to Increase Advanced Phase Change Material Market Opportunities.

Cold chain logistics involves the storage, transportation, and distribution of temperature-sensitive products, such as food, pharmaceuticals, and chemicals, ensuring they remain within a specific temperature range. Advanced PCMs absorb and release heat energy during their phase change, acting as thermal buffers. This helps maintain a consistent temperature range, protecting temperature-sensitive products from fluctuations caused by external factors.

Moreover, PCMs extend the duration of temperature control, reducing the reliance on mechanical cooling systems such as refrigerators and ice packs. This leads to lower energy consumption and operational costs. Additionally, by minimizing temperature excursions, PCMs help to preserve the quality and safety of temperature-sensitive products. This is particularly crucial for pharmaceuticals, vaccines, and perishable food items. Growing need for perishable food, temperature-sensitive pharmaceuticals (e.g., vaccines, etc.), and globalization of supply chains are driving the need for efficient and reliable cold chain logistics.

- According to JLL, a real estate company in India, in 2025, the cold chain segment of the country's logistics sector will experience a compound annual growth rate (CAGR) exceeding 20%. Thus, this will require significant quantities of advanced PCM to provide a stable temperature control mechanism, creating potential for the upcoming years.

Overall, the booming cold chain sector is expected to increase the advanced phase change material market opportunities.

Advanced Phase Change Material Market Segmental Analysis :

By Product Type:

Based on product type, the market is categorized into organic PCMs, inorganic PCMs, and eutectic PCMs.

Trends in Product Type:

- Increasing usage of paraffin wax as it is a popular choice within organic PCMs, offering good thermal properties and ease of handling.

- Growing trend of using eutectic PCMs to achieve specific melting points and improved thermal properties.

The organic PCMs segment accounted for the largest market share in 2024.

- Organic PCMs are a class of materials that undergo a phase change, typically from solid to liquid and vice versa, at specific temperatures. They are primarily composed of carbon-based compounds.

- Paraffins, derived from petroleum, are widely used organic PCMs due to their predictable phase change behavior. Additionally, non-paraffins, including fatty acids and esters, offer biodegradable and environmentally friendly options, catering to sustainability-focused applications.

- Organic PCMs offer several advantages, including long-term thermal cycling stability, non-toxicity, and no phase segregation during repeated use. Moreover, they are gentle on materials and do not cause corrosion.

- Increased research & development, coupled with companies publishing blogs have led to increased awareness of PCMs and their advantages.

- For instance, Thermtest, a leading provider of thermal conductivity measurement systems, published an article in December 2024, highlighting the potential of PCMs, their classification including organic PCMs, their composition, and diverse applications across sectors. This increased awareness is driving the adoption of organic PCMs, positively influencing the market growth.

- Overall, increasing awareness of organic PCMs, driven by research and targeted marketing, is driving the segment in the advanced phase change material market growth.

The eutectic PCMs segment is expected to grow at the fastest CAGR over the forecast period.

- Eutectic advanced phase change materials are mixtures of two or more components that melt and solidify at a single, fixed temperature. These materials exhibit a sharp phase change.

- Eutectic PCMs are a combination of organic-organic, organic-inorganic, or inorganic-inorganic components, tailored to achieve specific melting points and thermal properties.

- They have higher energy storage capacity compared to their individual components. Moreover, eutectic PCMs are engineered to meet diverse thermal requirements by varying their composition. Additionally,they exhibit low volume change during phase transitions, ensuring system stability.

- Furthermore, their ability to combine properties of both organic and inorganic components broadens their applicability in fields such as medical devices, electronics cooling, and cold chain logistics.

- As per the market analysis, increasing requirements for precise temperature control, energy efficiency, and sustainable solutions will drive the segment in the market for the forecasted years.

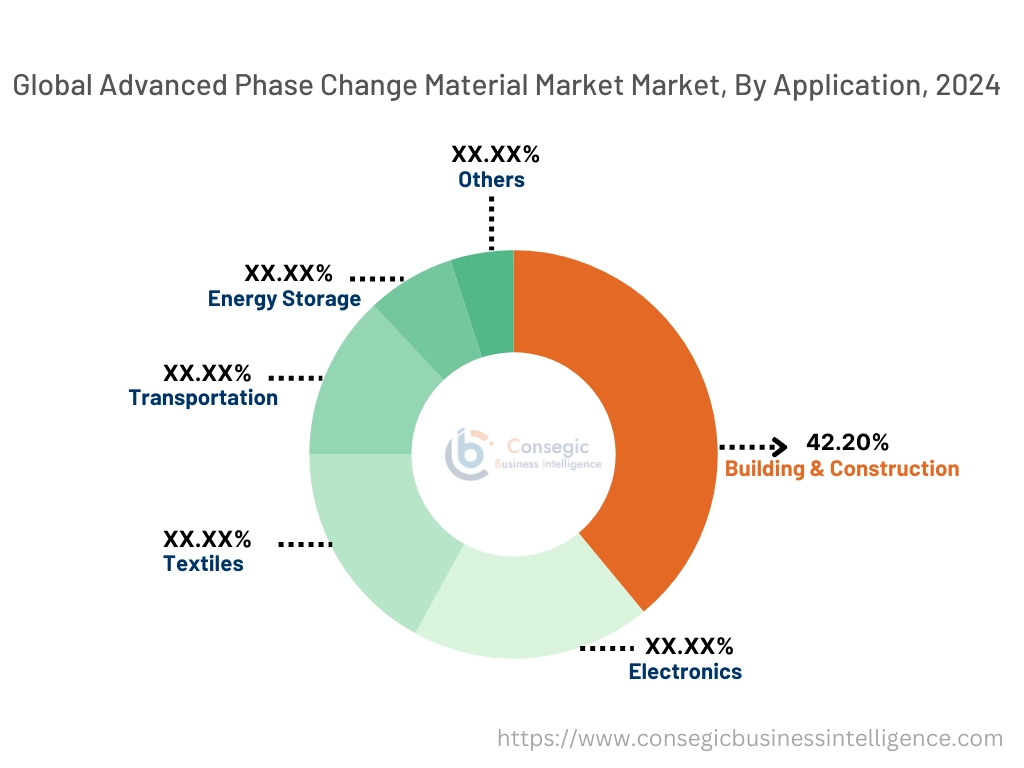

By Application:

The application segment is categorized into building & construction, electronics, textiles, transportation, energy storage, and others.

Trends in the Application:

- Growing need for PCMs in electric vehicles for battery thermal management and cabin climate control.

- Advancements in PCM-based thermal energy storage systems for renewable energy integration.

The building & construction segment accounted for the largest market share of 42.20% in 2024.

- PCMs are increasingly used in building and construction for energy-efficient thermal management. They are integrated into walls, ceilings, floors, and roofing materials to regulate indoor temperatures.

- PCMs absorb excess heat during the day and release it at night, maintaining comfortable indoor conditions. Applications include insulation panels, drywall, concrete, and window glazing, where PCMs enhance thermal energy storage and reduce heating and cooling demands.

- The use of PCMs in construction offers significant advantages, including improved energy efficiency by reducing the reliance on air conditioning and heating systems. This results in lower energy costs and reduced greenhouse gas emissions.

- Economic increase and favorable government initiatives have led to increased urbanization and infrastructure development,

- For instance, according to the Office for National Statistics, in 2022, the total value of new work infrastructure construction in the United Kingdom saw an 11.2% rise when compared to 2021. This has led to an increased need for PCMs as their integration into building materials allows for passive temperature control without mechanical intervention.

- Overall, as per the market analysis, the increasing urbanization and infrastructure development are driving segmental growth in the advanced phase change material industry.

The electronics segment is expected to grow at the fastest CAGR over the forecast period.

- Advanced phase change materials are extensively used in the electronics sector for thermal management. They are integrated into devices such as smartphones, laptops, tablets, and data center servers to dissipate heat generated during operation.

- PCMs absorb excess heat during phase transitions (solid to liquid) and release it when temperatures drop, ensuring components remain within safe operating limits. Common applications include heat sinks, thermal interface materials, and protective casings for electronic components.

- They enhance device longevity by preventing overheating, which damages sensitive components. Moreover, by maintaining stable operating temperatures, PCMs also improve the performance and reliability of electronic devices.Additionally, their passive cooling mechanism reduces the need for bulky cooling systems, enabling more compact and lightweight designs.

- This makes PCMs particularly valuable for portable devices and high-density electronics, where efficient thermal management is critical.

- As per the market analysis, the ever-growing need for advanced electronic devices, coupled with the rapid advancements in technology, creates the potential for the segment in the upcoming years.

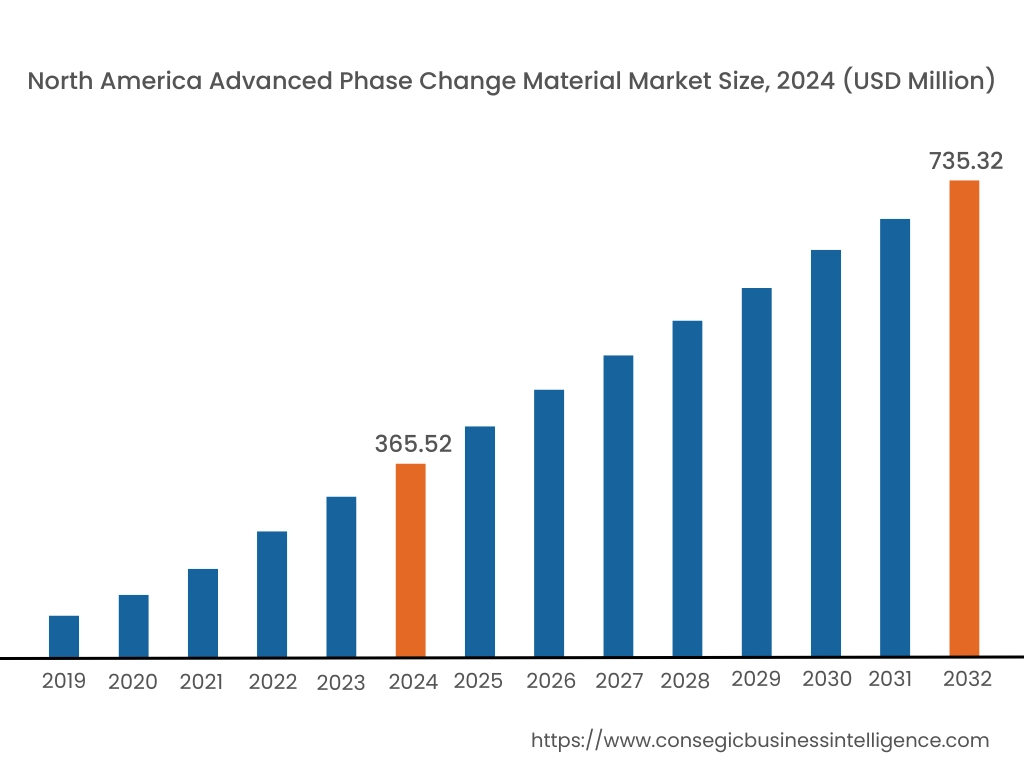

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

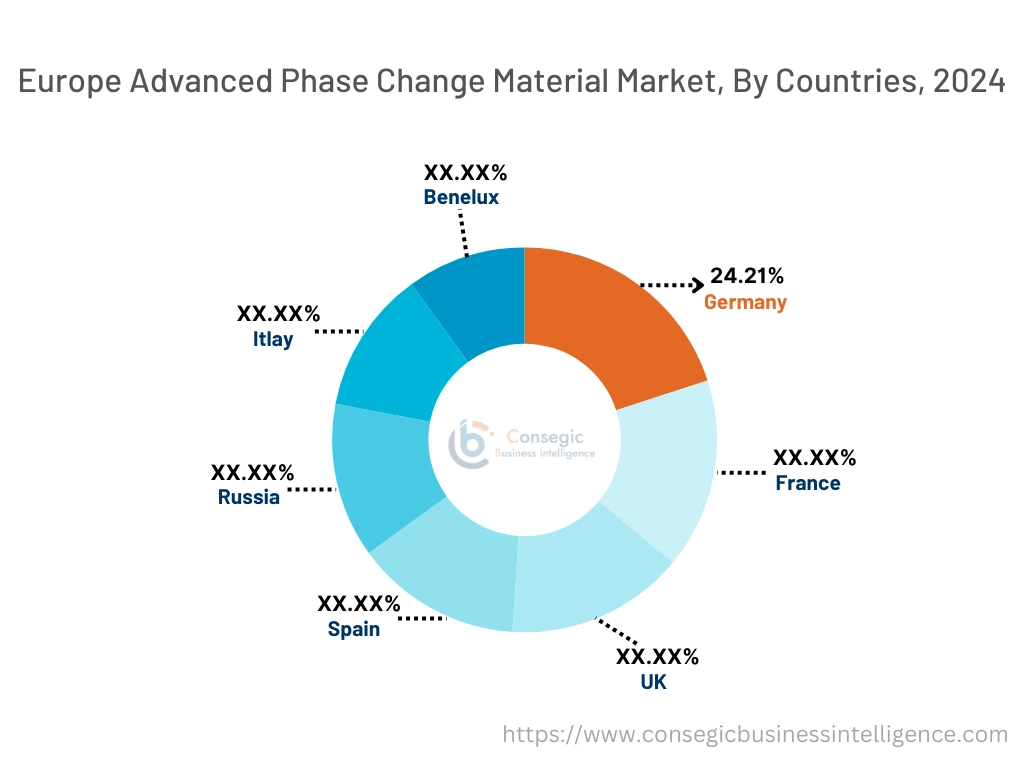

In 2024, Europe accounted for the highest advanced phase change material market share at 38.12% and was valued at USD 365.52 Million and is expected to reach USD 735.32 Million in 2032. In Europe, Germany accounted for the highest advanced phase change material market share of 24.21% during the base year of 2024. Europe boasts a robust network of research institutions, universities, and research centers actively engaged in PCM research and development. This strong foundation enables continuous innovation and the development of advanced PCM technologies. Moreover, European Union directives and national regulations promote energy efficiency and sustainable building practices.

- In March 2024, the European Parliament updated the Energy Performance of Buildings Directive to decrease greenhouse gas emissions and energy use in the EU's building sector. PCMs align well with these policies, as they significantly reduce energy consumption in buildings.

Additionally, European governments have implemented various initiatives and incentives to promote energy-efficient technologies, including PCMs. This support has stimulated investment in PCM research, development, and deployment. Furthermore, Europe has a well-established manufacturing sector, including the chemical and materials sectors, which provides a strong foundation for PCM production and commercialization. Overall, Europe's robust research infrastructure, stringent energy policies, government support, and well-established manufacturing sector are driving the growth of the market.

In North America, the advanced phase change material market is experiencing the fastest growth with a CAGR of 9.9% over the forecast period. North American consumers and businesses are early adopters of new technologies, including PCMs, which has fueled the market. Moreover, the robust construction sector in North America creates a substantial need for building materials and technologies that improve energy efficiency, making PCMs a valuable solution. Additionally, several leading companies in the PCM sector are headquartered in North America, contributing to the region's dominance. Furthermore, significant investments in research and development have led to advancements in PCM technology, particularly in the areas of performance, cost-effectiveness, and durability. Furthermore, stringent energy efficiency regulations in countries such as the US and Canada incentivize the adoption of energy-saving technologies such as PCMs.

Asia Pacific advanced phase change material market analysis states that several trends are responsible for the progress of the market in the region. The rapid urbanization in countries such as China and India is leading to increased demand for energy-efficient buildings and infrastructure. PCMs significantly improve the energy efficiency of buildings, making them a valuable solution. Moreover, the rapid industrialization in countries such as South Korea is driving demand for energy-efficient solutions, including PCMs, to optimize production processes and reduce energy costs. Additionally, the automotive sector in Asia-Pacific is expanding rapidly, and PCMs are being explored for applications in thermal management systems for vehicles, contributing to improved fuel efficiency and passenger comfort.

The Middle East and Africa (MEA) advanced phase change material market analysis states that the region is also witnessing a notable surge due to multiple trends. Many countries in the MEA experience extreme temperatures, making thermal management a significant challenge. PCMs help regulate indoor temperatures, reducing the reliance on energy-intensive HVAC systems. Moreover, the booming construction sector in the region offers substantial prospects for the application of PCMs in building materials and insulation. Additionally, the region's substantial oil and gas sector benefits from PCMs in various applications, such as thermal energy storage for oil and gas production, pipeline insulation, and cooling electronic equipment in harsh environments.

Latin America's advanced phase change material market size is also emerging. Trends such as rapid urbanization and industrialization are leading to increased energy requirements, particularly for cooling and heating, positively influencing the market share. Moreover, large-scale infrastructure projects, such as transportation systems significantly use PCM integration. Additionally, the rising middle class in Latin America is increasing demand for higher-quality products and improved living standards. PCM-based products enhance comfort and energy efficiency in homes and offices. Furthermore, the growing manufacturing and automotive sectors in the region are creating potential for PCMs in thermal management applications. Also, as renewable energy sources such as solar and wind power become more prevalent, PCMs play a crucial role in energy storage and grid stabilization.

Top Key Players and Market Share Insights:

The Advanced Phase Change Material market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Advanced Phase Change Material market. Key players in the Advanced Phase Change Material industry include-

- Croda International Plc (UK)

- Rubitherm Technologies GmbH (Germany)

- Kaneka Corporation (Japan)

- Encapsys, LLC (U.S.)

- PureTemp LLC (U.S.)

- RGEES, LLC (U.S.)

- Temprecision International (UK)

- PCM Products Ltd (UK)

- Henkel Corporation (Germany)

- Microtek Laboratories (U.S.)

Advanced Phase Change Material Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1,923.40 Million |

| CAGR (2025-2032) | 9.2% |

| By Product Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Advanced Phase Change Material market? +

In 2024, the Advanced Phase Change Material market is USD 958.87 Million.

Which is the fastest-growing region in the Advanced Phase Change Material market? +

North America is the fastest-growing region in the Advanced Phase Change Material market.

What specific segmentation details are covered in the Advanced Phase Change Material market? +

Product Type and Application segmentation details are covered in the Advanced Phase Change Material Market

Who are the major players in the Advanced Phase Change Material market? +

Croda International Plc (UK), Rubitherm Technologies GmbH (Germany), RGEES, LLC (U.S.), Temprecision International (UK), PCM Products Ltd (UK), Henkel Corporation (Germany), Microtek Laboratories (U.S.), Kaneka Corporation (Japan), Encapsys, LLC (U.S.), and PureTemp LLC (U.S.).