- Summary

- Table Of Content

- Methodology

Advanced High Strength Steel Market Size:

Advanced High Strength Steel Market size is growing with a CAGR of 9.1% during the forecast period (2025-2032), and the market is projected to be valued at USD 31,700.70 Million by 2032 from USD 15,891.23 Million in 2024.

Advanced High Strength Steel Market Scope & Overview:

Advanced high strength steel (AHSS) refers to a new class of steel that provides high strength (up to 2,000 MPa) and durability while maintaining formability. It comprises a wide range of complex multiphase microstructures, formed by ferrite, bainite, martensite, and retained austenite in different proportions. Such complex microstructures provide them with an excellent combination of mechanical properties and formability.

It offers a high strength-to-weight ratio, good formability, superior durability, corrosion resistance, and superior crash performance. These characteristic functionalities make it a critical component in automotive, construction, aerospace, and other sectors. Growing adoption of advanced high-strength steel to lightweight and improve fuel efficiency in automotive and aerospace sectors are the prominent factors supporting the market growth.

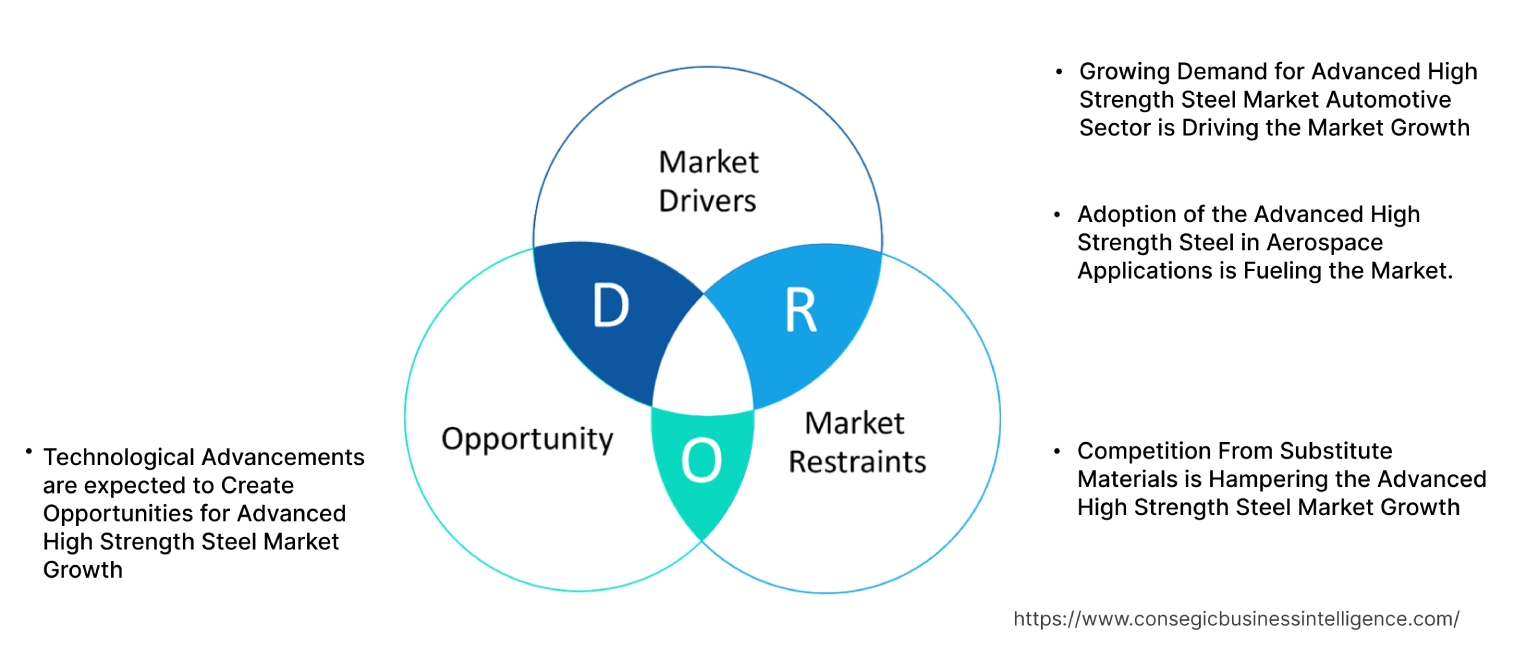

Key Drivers:

Growing Demand for Advanced High Strength Steel Market Automotive Sector is Driving the Market Growth

The automotive sector is undergoing a significant transformation by the adoption of advanced high strength steel. This surge in requirement for advanced steel types in automotive applications is primarily fueled by the increasing emphasis on vehicle lightweighting, enhanced safety, and stringent fuel efficiency regulations. AHSS offers a unique blend of high strength and ductility, enabling the use of thinner components in automotive construction. This not only reduces vehicle weight, improving fuel efficiency but also enhances safety by providing superior energy absorption capabilities during impacts.

Hence, this type of steel is steels are commonly used in various automotive components, including cross members, pillars, roof rails, frame extensions, shock towers, crush cans, and wheels. Moreover, as governments worldwide impose stricter fuel efficiency and emission standards, automakers are increasingly turning to lightweight materials like steel with high strength to meet emission regulations.

- For instance, according to the data published by the International Council on Clean Transportation in July 2024, it is stated that lightweight with high-strength steels including AHSS reduces vehicle emissions by 12%–15%. By reducing the overall weight of a vehicle, less energy is required to propel it, leading to lower fuel consumption and reduced greenhouse gas emissions.

Thus, owing to the aforementioned factors, the automotive sector’s focus on lightweight, safety, and fuel efficiency has made advanced high-strength steel a crucial material, driving advanced high strength steel market expansion.

Adoption of the Advanced High Strength Steel in Aerospace Applications is Fueling the Market.

The aerospace sector is increasingly adopting advanced high strength steel due to its exceptional strength-to-weight ratio, durability, and fatigue resistance. By reducing weight, it improves fuel efficiency and reduces operating costs. Additionally, its superior strength and durability enhance structural integrity, ensuring the safety and longevity of aircraft. Furthermore, its excellent fatigue resistance extends the service life of components subjected to cyclic loading during flight. By reducing material usage and improving manufacturing efficiency, it also contributes to lower production costs for aircraft manufacturers.

Hence, it is utilized in various critical components, including fuselage structures, landing gear systems, engines, turbine blades, and compressor discs among others. As a result, there is a growing focus on the development of AHSS plants for the aerospace sector.

- For instance, in October 2023, voestalpine opened the world’s most advanced special steel plant in Kapfenberg. The official opening of the state-of-the-art special steel plant Voestalpine marks a milestone in the production of pioneering high-performance materials including steel with advanced high strength for aerospace sectors.

Thus, as the aerospace sector prioritizes fuel efficiency, safety, and cost-effectiveness, the requirement for this steel is growing substantially, propelling the advanced high strength steel market expansion.

Key Restraints :

Competition From Substitute Materials is Hampering the Advanced High Strength Steel Market Growth

The wide availability of substitute options is significantly hindering the growth of the market. This factor is driven by the increasing preference for alternative materials including advanced aluminum alloys, high strength magnesium alloys, and carbon fiber-reinforced polymers among others. Advanced aluminum alloys, known for their lightweight and corrosion resistance, pose a significant threat to this steel, especially in applications where weight reduction is paramount. High strength magnesium alloys, even lighter than aluminum, offer high specific strength.

Additionally, carbon fiber-reinforced polymers excel in terms of strength-to-weight ratio, stiffness, and fatigue resistance. Moreover, high-strength low-alloy steels, while offering a good balance of strength and ductility, are generally less expensive. These alternative materials compete with this steel in various sectors, particularly automotive and aerospace. Their availability puts pressure on its pricing and limits its market.

Future Opportunities :

Technological Advancements are expected to Create Opportunities for Advanced High Strength Steel Market Growth

Technological advancements in the production of AHSS such as advanced cooling systems are expected to transform the market. Cooling systems such are dry flash cooling and multi-purpose interrupted cooling systems are supporting the improvement in the manufacturing process. Dry flash cooling involves rapid cooling of hot steel using high-velocity gas, resulting in a fine-grained microstructure that improves strength, ductility, and fatigue resistance.

Multi-purpose interrupted cooling systems offer precise temperature control and cooling rate adjustments, enabling the tailoring of steel properties to specific applications. Additionally, there is a growing focus on the development of sustainable advanced high-strength steel such as the development of recyclable steel that reduce the requirement for virgin raw materials and lower energy consumption.

- For instance, SSAB announced that starting in 2026 it will offer fossil-free and infinitely recyclable AHSS.

These advancements are set to create opportunities for innovation and sustainable development in the future years.

Advanced High Strength Steel Market Segmental Analysis :

By Product Type:

Based on product type, the market is categorized into dual phase steels, transformation-induced plasticity steels, complex phase steels, martensitic steels, twinning-induced plasticity steels, austenitic stainless steels, and others.

Trends in the Product Type:

- Incorporating new alloying elements to enhance specific properties such as corrosion resistance, high-temperature performance, or improved weldability in dual phase steels.

- Developing surface treatments to enhance the wear resistance, paint adhesion, or corrosion protection of dual phase steel components.

The dual phase steel segment accounted for the largest market share in 2024.

- Dual-phase (DP) steels consist of two primary phases including a soft, ductile ferrite phase and a hard, strong martensite phase. This unique microstructure provides an excellent balance of strength, ductility, and formability.

- The mechanical properties of DP steels typically include low yield strength, high strain hardening rate, high ultimate tensile strength, and good ductility. These steels also exhibit excellent formability, making them ideal for complex shaping and stamping processes.

- Owing to these advantages, this steel is widely used in automotive body panels, structural components, and chassis components among others.

- The automotive sector is a major driver, leveraging DP steels to meet stringent fuel economy and safety standards. The high strength-to-weight ratio of DP steels enables the development of lighter vehicles, reducing fuel consumption and CO2 emissions.

- Thus, dual-phase steels, with their balance of strength, ductility, and formability, are widely used in the automotive sector to enhance vehicle safety, fuel efficiency, and design flexibility.

The other segment is expected to grow at the fastest CAGR over the forecast period.

The other segment includes third-generation steel, ferritic-bainitic steel, and others.

- Third-generation advanced high strength steels are engineered to possess exceptional formability, as demonstrated by their performance in tensile, shear edge, and bending tests. This enhanced formability is achieved through a specific microstructure, often involving a combination of retained austenite, bainite, martensite, ferrite, and precipitates, each phase contributing unique properties in specific proportions and distributions. They present increased elongation as well as increased strength.

- Ferritic-Bainitic steel offers a unique combination of high strength and excellent formability. It consists of a fine-grained microstructure composed of ferrite and bainite phases.

- Third-generation steel presents a prominent role in the automotive sector with cost-cutting and lightweight potential. As a result, there is growing emphasis on the adoption of this type of steel in automotive applications.

- For instance, in October 2024, ThyssenKrupp Steel launched its third-generation Advanced High-Strength Steel, jetQ. This innovative steel is specifically designed for complex crash structures, enabling the construction of lighter and more resource-efficient vehicle bodies.

- As a result, this innovative steel contributes to the development of safer, more efficient, and sustainable vehicles creating potential for segment expansion in the upcoming years.

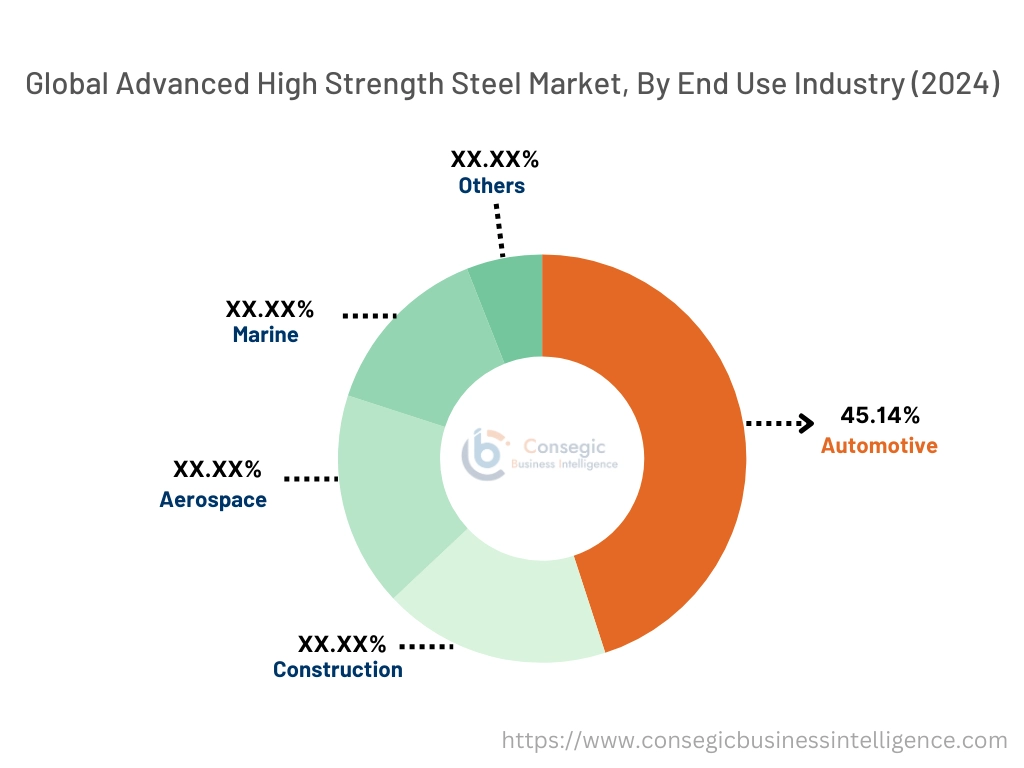

By End-Use Industry:

Based on end use industry, the market is categorized into automotive, construction, aerospace, marine, and others.

Trends in the End Use Industry:

- The transition to electric vehicles is a trend supporting the requirement for lightweight and high-strength materials to improve battery range and overall vehicle performance.

- The focus on sustainable construction practices is leading to the adoption of advanced high-strength steel for its durability and longevity, reducing the need for frequent replacements.

The automotive segment accounted for the largest market share of 45.14% in the year 2024.

- The automotive sector is the primary consumer of advanced high-strength steel. This is due to its ability to enhance vehicle performance, safety, and fuel efficiency.

- It is used in various automotive components, including body panels, structural components, chassis components, and engine components. Its high strength-to-weight ratio enables the production of lighter vehicles, reducing fuel consumption and emissions.

- Additionally, it contributes to enhanced vehicle safety by improving crashworthiness and occupant protection. The excellent formability of this steel allows for complex designs, giving automakers greater design flexibility.

- As the automotive sector continues to prioritize fuel efficiency, safety, and design innovation, the requirement for this steel remains strong. Rising vehicle production necessitates demand for this type of steel.

- For instance, according to the data provided by TD Economics in April 2024, automotive production activity has grown significantly with 15.6 million vehicles produced in North America in 2023, a 9.6% gain relative to 2022. U.S. light vehicles sales in turn grew 12.7% in 2023. Consequently, there is an increased need for advanced high-strength steel to meet the growing requirement for lightweight, durable, and high-performance automotive components.

- Thus, as per analysis, the automotive sector’s increasing reliance on advanced high-strength steel is driven by its ability to enhance vehicle performance, safety, and fuel efficiency.

The aerospace segment is expected to grow at the fastest CAGR over the forecast period.

- Advanced high-strength steel serves as a crucial material in the aerospace sector, offering a combination of strength, weight reduction, and cost-effectiveness.

- It is used in the construction of aircraft fuselages, providing the necessary strength and rigidity while minimizing weight. It's also employed in landing gear components, where its high strength and durability are essential.

- Additionally, it finds applications in certain engine components, such as brackets and mounts, due to its high strength and lightweight properties.

- By leveraging this advanced steel, the aerospace sector is able to design and manufacture aircraft that are lighter, more fuel-efficient, and safer. This contributes to reduced operational costs, lower environmental impact, and improved overall performance.

- As a result, as per advanced high strength steel market analysis, this advanced type of steel is becoming a critical material in the modern aerospace sector.

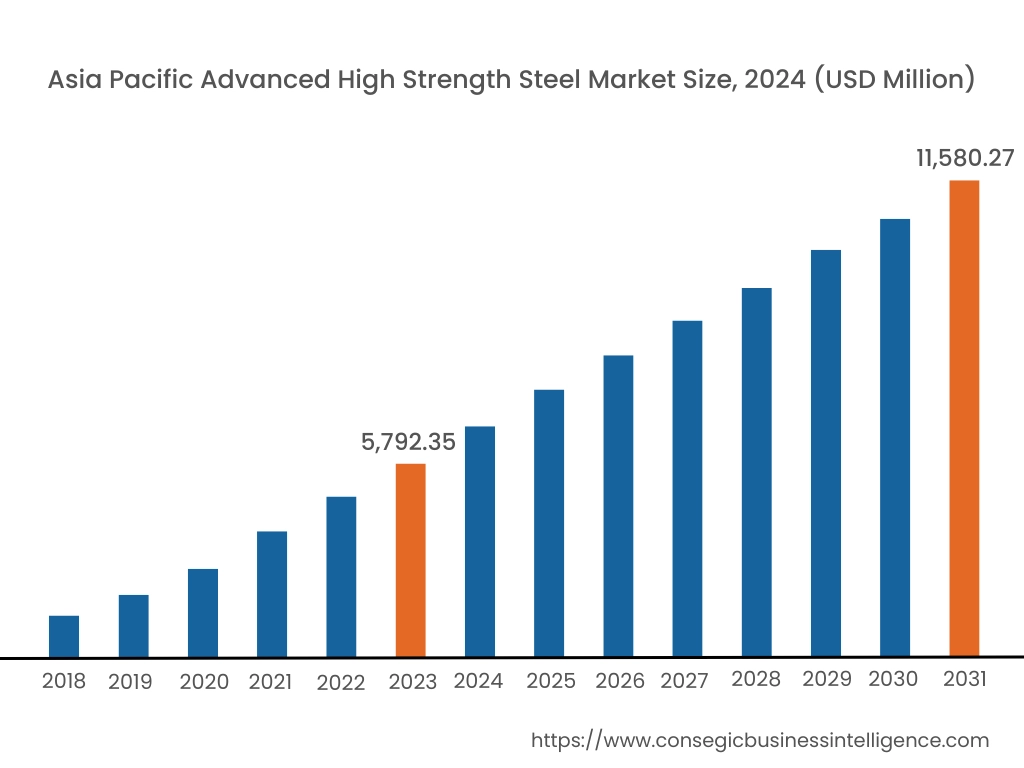

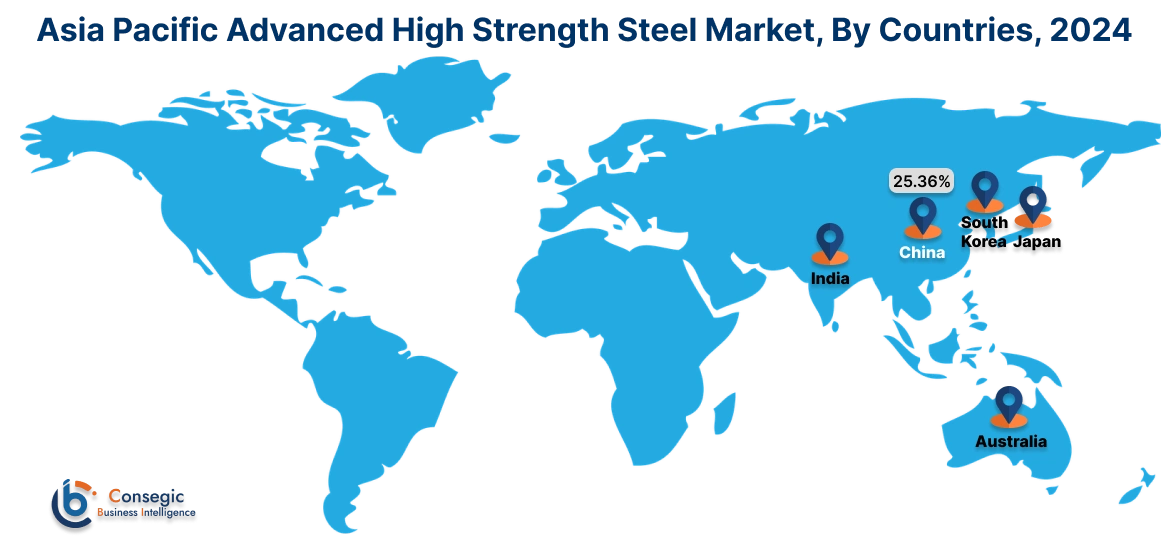

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Aisa Pacific accounted for the highest market share at 36.45% and was valued at USD 5,792.35 Million and is expected to reach USD 11,580.27 Million in 2032. In Asia Pacific, China accounted for the highest market share of 25.36% during the base year of 2024. Asia Pacific dominates the global advanced high strength steel market, primarily due to the rapidly accelerating automotive manufacturing in countries such as China, India, and South Korea. Governments in the region are promoting infrastructure development and automotive manufacturing, further boosting the need for this steel. The growing vehicle production creates a higher requirement for steel with advanced high strength.

- For instance, according to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with 11.6% year-on-year growth.

Additionally, countries across the region have witnessed rapid industrialization, leading to increased requirements for automobiles, both for personal and commercial use. The increasing need for affordable vehicles, coupled with rising disposable incomes, is fueling the market. Moreover, the region's focus on lightweight materials and fuel-efficient vehicles is driving the requirement for specialized materials such as steel with advanced high strength.

Furthermore, the increasing emphasis on electric vehicles is creating the requirement for this steel to lightweight the body structures, particularly for the battery enclosure, providing crucial protection to the battery pack during crashes while minimizing overall vehicle weight, thus maximizing range and improving safety. As per analysis, the combination of the aforementioned factors and trends is driving a substantial trajectory in the Asia Pacific advanced high strength steel market share.

North America is experiencing the fastest growth with a CAGR of 9.8% over the forecast period. The advanced high strength steel market trend across the region is attributed to factors such as the presence of major automotive manufacturers and a strong emphasis on vehicle durability and fuel efficiency. Key factors driving the market include increasing vehicle production, stringent emission regulations, and the rising requirement for luxury and high-performance vehicles. The region's focus on vehicle lightweighting and safety regulations is propelling the need for advanced steel grades. In addition to the automotive sector, it is also finding increasing applications in the construction sector in North America. Its superior strength-to-weight ratio and durability make it suitable for various construction projects. Collectively, as per analysis, the aforementioned factors create a favorable environment for advanced high strength steel market demand across North America.

Europe presents a significant contribution to the advanced high strength steel market analysis. The European automotive sector market is mature, creating constant requirements for manufacturing materials. Additionally, factors including stringent environmental regulations, increasing focus on fuel efficiency, and the rising requirement for premium and luxury vehicles are boosting the requirement for steel with advanced high strength. Moreover, the increasing emphasis on sustainable construction practices, such as the trend of lightweight buildings to reduce energy consumption, fuels the market. Furthermore, the growing need for high-strength steel in infrastructure projects, including bridges and railways, contributes to the region's significant consumption. Collectively, rising investments in electric vehicles and lightweighting technologies, government initiatives promoting sustainable construction, and increasing urbanization and infrastructure development are supporting the advanced high strength steel market trend in Europe.

Latin America is an emerging region in the advanced high strength steel market share, with significant potential for innovations. The Latin American automotive sector is experiencing a significant trajectory, driven by increasing disposable incomes, government initiatives, and rising requirements for personal mobility. This trend has led to a corresponding increase in the need for this steel for automobile manufacturing. Additionally, rapid urbanization and infrastructure development are driving the need for efficient transportation solutions. This includes the rise in public transportation systems. Government initiatives and investments in infrastructure projects, such as roads, bridges, and railways, are driving the demand for high-strength steel. This analysis presents a substantial potential for advanced high strength steel manufacturers and suppliers to capitalize on this demand.

The Middle East and Africa (MEA) region is witnessing notable advanced high strength steel market demand characterized by significant potential. The MEA regions are experiencing rapid industrialization and urbanization, driving significant rise in the automotive sector. The automotive sector in the Middle East and Africa is expanding, with increased production of both passenger cars and commercial vehicles. This growth is driving the requirement for steel with advanced high strength. Additionally, as disposable incomes increase, particularly in the Gulf Cooperation Council (GCC) countries, there is a surge in demand for luxury and premium vehicles. Moreover, governments in the region are investing heavily in mega-projects and infrastructure development, leading to increased construction activity. This creates the adoption of high strength building materials, including advanced high strength steel. Collectively, the aforementioned factors create a favorable environment for advanced high strength steel market opportunities across the MEA.

Top Key Players and Market Share Insights:

The Advanced High Strength Steel market is highly competitive with major players providing precise products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Advanced High Strength Steel market. Key players in the Advanced High Strength Steel industry include-

- ArcelorMittal (Luxembourg)

- Tata Steel (India)

- JSW (India)

- AK Steel International B.V. (U.S.)

- Nucor (U.S.)

- United States Steel Corporation (U.S.)

- voestalpine Stahl GmbH (Austria)

- SSAB (Sweden)

- Cleveland-Cliffs Inc. (U.S.)

- thyssenkrupp Steel (Germany)

Recent Industry Developments :

Product Launch:

- In October 2024, ThyssenKrupp Steel launched its third-generation Advanced High-Strength Steel, jetQ. This steel is designed for complex crash structures, enabling the construction of lighter and more resource-efficient vehicle bodies.

Advanced High Strength Steel Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 31,700.70 Million |

| CAGR (2025-2032) | 9.1% |

| By Type |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Advanced High Strength Steel market? +

In 2024, the Advanced High Strength Steel market is USD 15,891.23 Million.

Which is the fastest-growing region in the Advanced High Strength Steel market? +

North America is the fastest-growing region in the Advanced High Strength Steel market.

What specific segmentation details are covered in the Advanced High Strength Steel market? +

Type and End Use Industry segmentation details are covered in the Advanced High Strength Steel market.

Who are the major players in the Advanced High Strength Steel market? +

ArcelorMittal (Luxembourg), Tata Steel (India), and United States Steel Corporation (U.S.) are some of the major players in the market.