Adhesive Resin Market Size:

Adhesive Resin Market size is growing with a CAGR of 4.8% during the forecast period (2025-2032), and the market is projected to be valued at USD 25,170.81 Million by 2032 from USD 17,445.37 Million in 2024.

Adhesive Resin Market Scope & Overview:

An adhesive resin refers to the primary polymer material that provides the adhesive/adhesion properties. These resins are designed to bond different materials together by creating strong, durable bonds. Several types of resins used in the formulation of adhesives are epoxy, acrylic, polyurethane, silicone, phenolic, polyamide, polyvinyl acetate (PVA), ethylene vinyl acetate (EVA) and others.

These resins offer a range of properties that make them versatile materials for bonding various surfaces. They exhibit strong bonding capabilities, versatility in adhering to different materials, and resistance to environmental factors such as water, heat, chemicals, and UV radiation. Additionally, many of these resins offer fast curing times, high strength-to-weight ratios, and flexibility, making them suitable for a wide range of applications across industries.

Adhesive resins find a range of applications in construction and building materials, automotive manufacturing, electronics, medical devices, woodworking, consumer products, packaging, and others. Growing requirements for high-performance adhesives, increasing focus on the adoption of water-based resins, and the rising preference for sustainably sourced resins are some of the prominent factors propelling the growth.

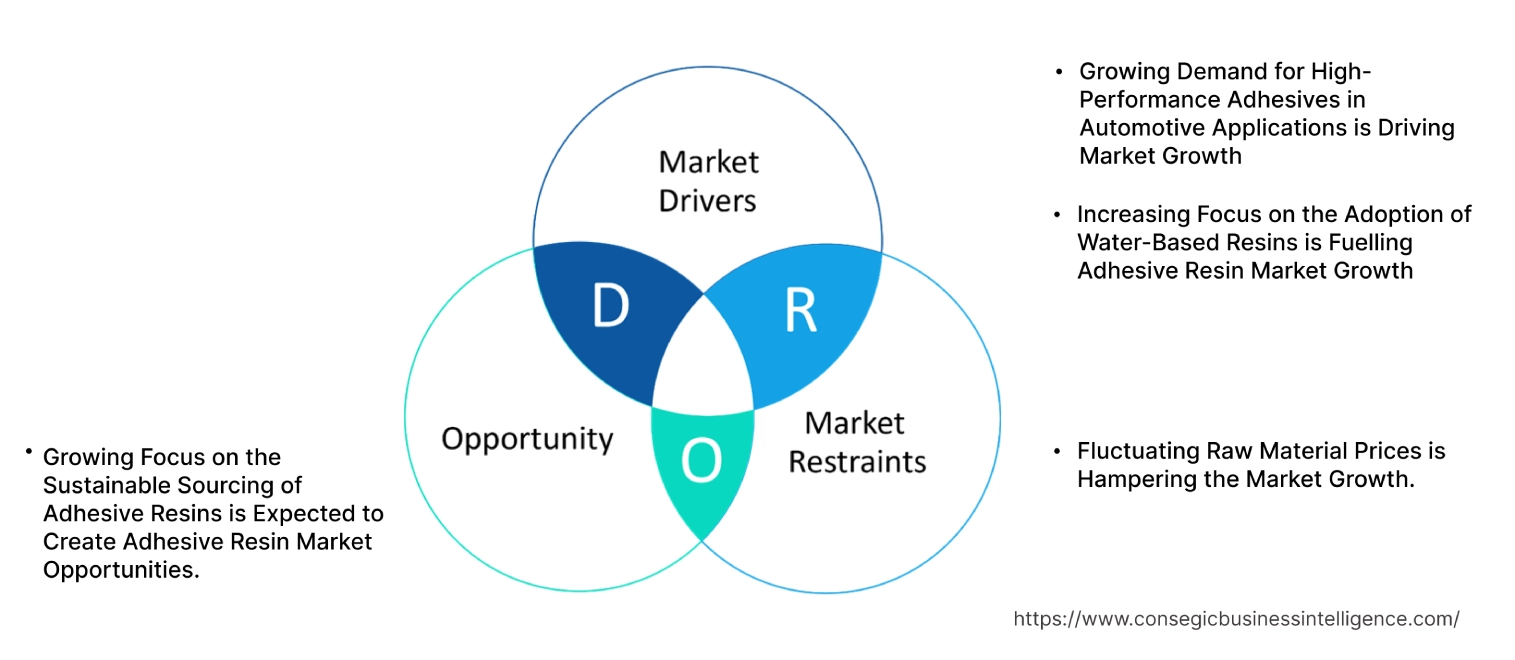

Adhesive Resin Market Dynamics - (DRO) :

Key Drivers:

Growing Demand for High-Performance Adhesives in Automotive Applications is Driving Market Growth

The automotive sector is a significant driver of the adhesive resin market, particularly due to the increasing demand for high-performance adhesives. This requirement is fueled by the industry's emphasis on lightweight, complex designs, improved aesthetics, and efficient manufacturing processes. High-performance adhesives offer strong, durable, and lightweight bonding solutions, making them suitable for bonding diverse materials including aluminum, carbon fiber, and plastics.

These adhesives enable seamless joints, eliminating the need for traditional fasteners and enhancing vehicle aesthetics. Additionally, they provide excellent durability and resistance to environmental factors, ensuring the longevity of vehicle components. High-performance adhesives are well-suited for automated assembly processes, leading to increased production efficiency. This requirement for high-performance adhesives in automotive applications is creating the development of innovative products.

- For instance, in September 2024, Covestro developed Dispercoll U PLUS waterborne polyurethane adhesive that prioritizes performance and efficiency for automotive interiors. It significantly improves heat and climate resistance, addressing the challenges of aging in automotive interiors due to extreme heat and ensuring long-term stability in adhesive bonding performance.

As a result, as the automotive industry continues to innovate and evolve, the requirement for high-performance adhesive resins remains strong, driving the overall adhesive resin market growth.

Increasing Focus on the Adoption of Water-Based Resins is Fuelling Adhesive Resin Market Growth

The growing adoption of water-based resins is significantly driving the market. Water-based resins, also known as waterborne resins, are polymeric resins that use water as the main carrier medium instead of a solvent. Growing focus on the adoption of these resins is primarily fueled by increasing environmental concerns and stringent regulations governing volatile organic compounds (VOCs).

Water-based resins have significantly lower VOC emissions compared to solvent-based resins. Additionally, these resins are less flammable than solvent-based resins, reducing the risk of fire hazards in the manufacturing and application processes of adhesives. These resins are also highly versatile and are suitable for a wide range of applications, such as packaging, labeling, construction, and woodworking. These benefits are leading to the development of water-based resins for adhesive formulations.

- For instance, in June 2023, DIC Corporation announced the launch of the HYDRAN GP series of waterborne polyurethane resins. The new resins have a higher solid content than conventional water-based polyurethane resins and contain no amines, helping customers to shorten process times and lessen odors, as well as reduce greenhouse gas emissions and volatile organic compounds (VOCs). The company has planned to promote this series globally for adhesive applications.

Thus, the combination of environmental benefits, versatility, and recent advancements in water-based resin technology is boosting significant development of the market.

Key Restraints :

Fluctuating Raw Material Prices is Hampering the Market Growth.

Many adhesive resins are derived from petrochemical feedstocks such as crude oil and natural gas. Fluctuations in these commodity prices directly translate to increased production costs for manufacturers of resin. As input costs rise, manufacturers find it difficult to pass on these additional expenses to consumers, leading to reduced profit margins. Extreme price fluctuations lead to supply shortages of key raw materials, disrupting production schedules and impacting the availability of these resins.

Additionally, volatile raw material prices create uncertainty in the market, making it difficult for adhesive manufacturers to accurately forecast costs and set competitive prices. It also discourages manufacturers from investing in new production facilities or research and development, hindering long-term development. As a result, considering the aforementioned factors fluctuations in the prices of raw materials are limiting the adhesive resin market expansion.

Future Opportunities :

Growing Focus on the Sustainable Sourcing of Adhesive Resins is Expected to Create Adhesive Resin Market Opportunities.

The increasing emphasis on sustainability and environmental friendliness has led to growing requirements for eco-friendly adhesive resins. Stricter environmental regulations, heightened consumer awareness, corporate social responsibility initiatives, and government incentives are driving preference for sustainable sourcing of resins employed in the adhesive’s formulation. As consumers and businesses become increasingly aware of the environmental impact of products, there is a growing requirement for sustainably sourced materials. Manufacturers are responding to this by developing biobased, biodegradable, and recyclable adhesive resins.

- For instance, in May 2024, Lubrizol announced the expansion of its bio-based thermoplastic polyurethane portfolio, BioTPU for adhesives. The expansion of Bio TPU solutions, commercialized as Estane and Pearlbond ECO TPU, supports the acceleration of Lubrizol’s sustainability focus for adhesive formulators.

These eco-friendly resins not only reduce environmental impact but also promote sustainable manufacturing practices. As a result, based on the market analysis, by prioritizing sustainability, the adhesive resin industry is expected to create opportunities for manufacturers to develop innovative resin solutions, increase consumer appeal, and enhance brand reputation.

Adhesive Resin Market Segmental Analysis :

By Type:

Based on type, the market is categorized into epoxy, acrylic, polyurethane, silicone, phenolic, polyvinyl acetate (PVA), ethylene vinyl acetate (EVA), and others.

Trends in the Type:

- Focus on developing environmentally friendly resin formulations to reduce VOC emissions

- Focus on developing flame-retardant and high-temperature resins.

The epoxy segment accounted for the largest market share in 2024.

- Epoxy resins are a type of thermosetting polymer known for their exceptional strength, durability, and resistance to chemicals and heat.

- Their excellent adhesion to various substrates, including metals, ceramics, wood, and composites, makes them suitable for a wide range of applications. Furthermore, their chemical resistance and electrical insulating properties make them ideal for growing environments.

- For structural bonding, epoxy adhesives are employed in critical applications across industries such as aerospace, automotive, and construction. They are essential in the assembly of electronic components. In the construction sector, epoxy adhesives find applications in flooring, countertop installation, and tile bonding. The automotive sector leverages epoxy adhesives for bonding body panels and engine components.

- The increasing requirement for high-performance adhesives, coupled with advancements in formulation developed for tailored applications, is driving the adhesive resin market expansion.

- For instance, in March 2024, Panacol developed a new epoxy resin adhesive. Structalit 5826 VT is specifically for bonding filters for oil, gas, and particle filtration. Structalit 5826 VT is highly resistant to fluids and media and is very suitable for bonding filters used in shipbuilding and engine construction, exhaust gas purification systems, and the renewable energy sector.

- As a result, epoxy resins, with their exceptional properties and diverse applications, serve a crucial role in the adhesive sector thus driving the trend of the segment

The acrylic segment is expected to grow at the fastest CAGR over the forecast period.

- Acrylic resins are a type of thermoplastic polymer derived from acrylic acid. They are known for their versatility, clarity, and durability. In adhesives, acrylic resins play a crucial role, offering a wide range of benefits and applications.

- Their ability to be tailored to exhibit various properties, such as flexibility, hardness, and adhesion, makes them suitable for a wide range of applications. Acrylic adhesives excel in adhesion to diverse surfaces, including metals, plastics, paper, and glass. Their resistance to UV light, moisture, and temperature fluctuations ensures long-lasting performance.

- Hence, acrylic resins are employed for adhesives in numerous sectors including packaging, construction, and automotive among others.

- Thus, acrylic resins, with their versatility, performance, and environmental friendliness, are poised to continue innovation in the adhesive sector. As technology advances and new applications emerge, acrylic adhesives will remain a key component in various sectors, ensuring strong, durable, and sustainable bonding solutions.

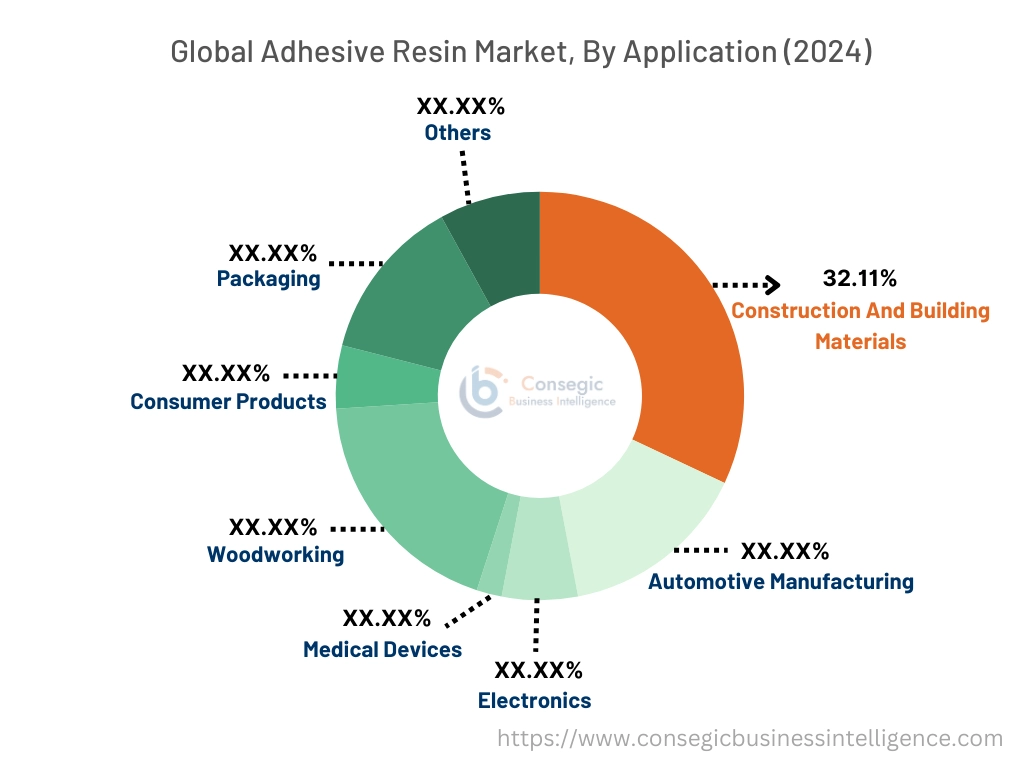

By Application:

Based on applications, the market is categorized into construction and building materials, automotive manufacturing, electronics, medical devices, woodworking, consumer products, packaging, and others.

Trends in Application:

- The shift towards sustainable building practices is driving eco-friendly adhesive resins.

- Adhesive bonding is replacing traditional mechanical fastening methods to improve vehicle performance and reduce weight.

The construction and building materials segment accounted for the largest market share of 32.11% in the year 2024.

- Adhesive resins play a crucial role in the construction and building materials sector, providing strong, durable, and versatile bonding solutions.

- Construction and building materials are the primary users of these resins due to their wide range of applications, including bonding wood, metal, and other materialssealing joints, adhering tiles and flooring, and constructing composite structures.

- They are used to repair concrete structures, bond composite materials, and install tiles and flooring. Additionally, these resins serve as sealants and gaskets, ensuring watertight and airtight connections. In roofing and waterproofing applications, these resins provide durable and weather-resistant solutions.

- Beyond these primary uses, these resins find applications in insulation and decorative finishes, contributing to the overall construction and building process.

- Moreover, the rapidly growing commercial construction, growing focus on home renovation and remodeling, and development of modular or prefabricated buildings are the factors fueling the requirement for adhesives. This in turn boosts the requirement for adhesive resins in construction and building materials applications.

The electronics segment is expected to grow at the fastest CAGR over the forecast period.

- electronics applications are experiencing rapid development, driven by technological advancements and increasing requirements for electronic devices. This, in turn, is fueling the demand for high-performance adhesive resins for bonding electronic components, sealing devices, and insulating electrical connections.

- As electronic components become smaller and more complex, there is a growing need for high-performance adhesives that provide excellent bonding strength, electrical insulation, and durability.

- Additionally, the rise of wearable electronics, such as smartwatches and fitness trackers, further fuels the requirement for flexible and durable adhesives.

- Moreover, the semiconductor sector relies on advanced adhesives to bond delicate components and ensure reliable performance. These factors collectively create the requirement for highly effective resins. Furthermore, the development of innovative adhesive solutions for electronics is creating the requirement for resins.

- For instance, in July 2023, Panacol launched Structalit 5604, an extremely fast-curing adhesive that is specifically developed for bonding SMDs (Surface Mount Devices) to printed circuit boards. The adhesive is based on epoxy resin. It is particularly shock-resistant and durably adheres to FR4 printed circuit boards, metals, and epoxy-based molded materials. Due to its high glass transition range of >115°C, the adhesive is ideal for electronic component assembly.

- As a result, the convergence of technological advancements, miniaturization of electronic components, and the rise of wearable electronics are driving the requirement and trends for high-performance adhesive resins.

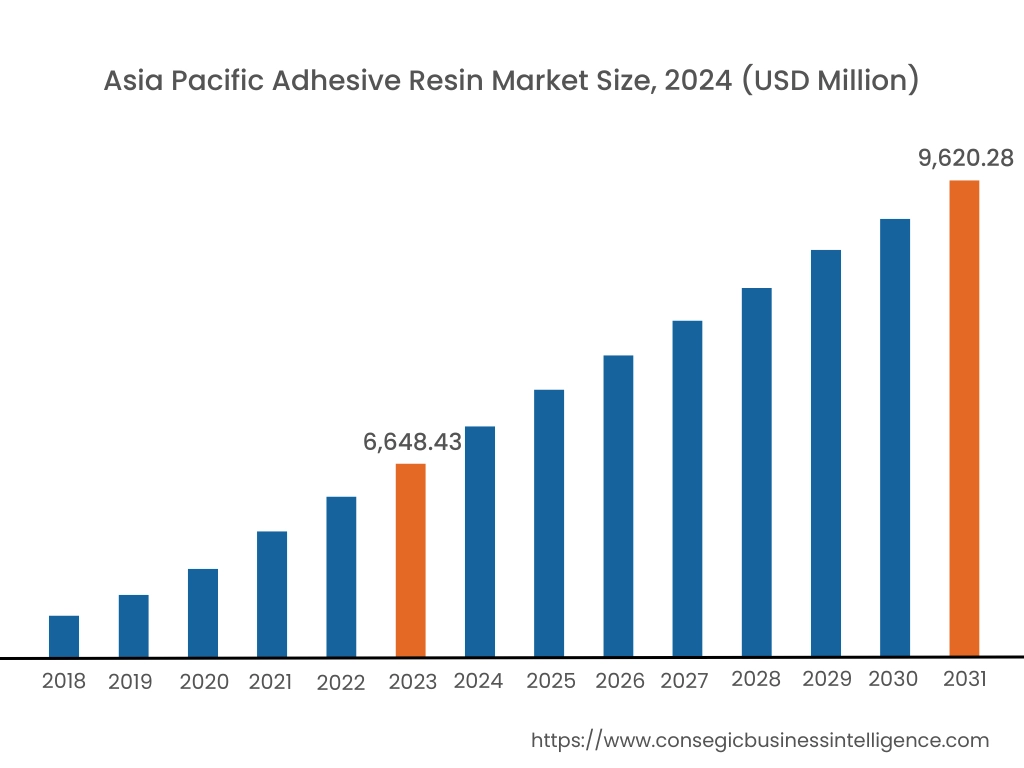

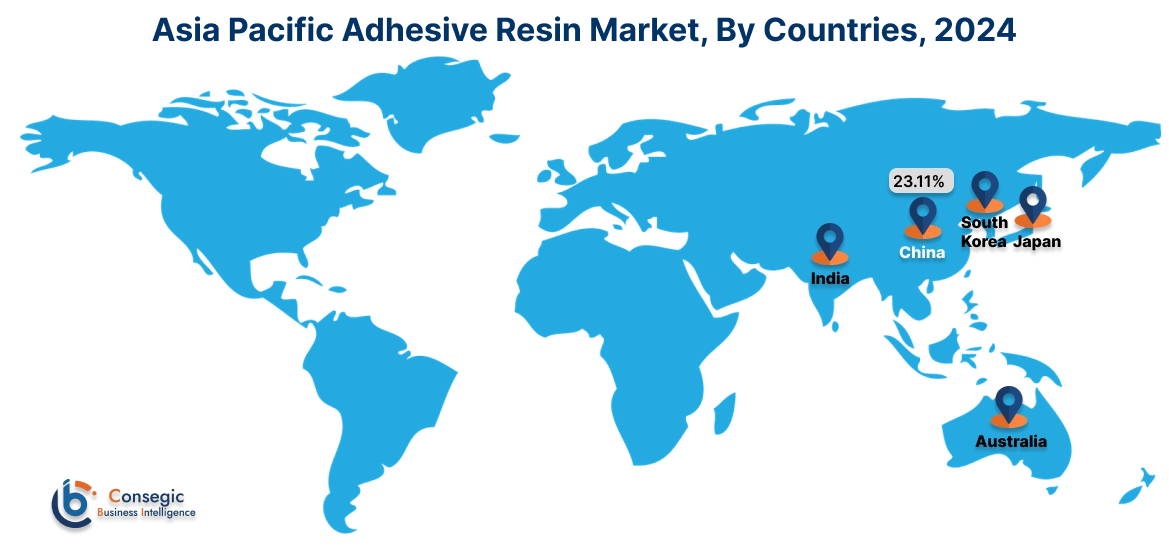

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Aisa Pacific accounted for the highest market share at 38.11% and was valued at USD 6,648.43 Million and is expected to reach USD 9,620.28 Million in 2032. In Asia Pacific, China accounted for the highest market share of 23.11% during the base year of 2024. Asia Pacific dominates the global adhesive resin market, primarily due to infrastructure development, development of manufacturing, automotive production, and electronics manufacturing among others. Massive infrastructure investments, a booming manufacturing sector, and increasing consumer requirements for various goods are driving the requirement for construction, industrial, and packaging adhesives.

The region's automotive and electronics industries, particularly in countries like China, India, Japan, and South Korea, are significant consumers of these resins for assembly, sealing, and bonding applications. Moreover, governments in the region are promoting infrastructure development and automotive manufacturing, further boosting the requirement for these resins to bond various automotive components. The growing vehicle production creates a higher requirement for these resins.

- For instance, according to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with 11.6% year-on-year growth. Thus the integration of adhesive resin in automotive manufacturing is increasing thus driving the market.

Based on the analysis, the combination of the aforementioned factors and trends is driving a substantial trajectory in the Asia Pacific adhesive resin market share.

North America is experiencing the fastest growth with a CAGR of 5.2% over the forecast period. The adhesive resin market trend across the region is attributed to factors such as the presence of major automotive manufacturers and a strong emphasis construction sector. Key drivers of this development include the robust construction sector, particularly in the U.S. and Canada, which requires these resins for residential and commercial construction. The automotive sector, especially in the U.S., is another significant consumer of high-performance adhesives used in vehicle assembly and repair. The packaging sector, particularly in the U.S., utilizes a wide range of resins for packaging materials. Additionally, the aerospace sector in the U.S. requires specialized adhesives for bonding and sealing components. Collectively, these factors create favorable adhesive resin market demand across North America.

Europe presents a significant contribution to the adhesive resin market analysis. The growth is primarily driven by the automotive and construction industries. The European automotive sector, known for its technological advancements heavily relies on these resins for bonding, sealing, and assembly processes. The increasing adoption of lightweight technologies further fuels the requirement for high-performance resins. Additionally, the European construction sector is a significant consumer of these resins for various applications, such as bonding tiles, The growing emphasis on sustainable construction practices is driving the requirement for eco-friendly adhesive solutions. Based on the market analysis, this strong focus on sustainability is a defining characteristic of the European market, with consumers and businesses increasingly seeking low-VOC, water-based, and biodegradable adhesive resins. This shift towards sustainable solutions is driving the European adhesive resin market trends.

The Middle East and Africa (MEA) regions are witnessing notable adhesive resin market demand characterized by significant potential. This region's rapid urbanization, infrastructure development, and growing population are driving the need for construction materials. Governments in the region are investing heavily in mega-projects and infrastructure development, leading to increased construction activity. Additionally, the rising middle class and economic diversification are fueling requirements for housing and commercial spaces. The expanding packaging sector, fueled by e-commerce and consumer goods, necessitates these resins for labeling, selling, and bonding. The furniture sector is experiencing a rise in utilizing these resins for wood bonding and upholstery. As a result, based on the market analysis, the aforementioned factors create adhesive resin market opportunities and trends in the MEA.

Latin America is an emerging region in the adhesive resin market share, with significant potential for innovation. The region's rapid urbanization and infrastructure development are driving the necessity for construction materials, further creating the demand for these resins. Government initiatives to improve infrastructure, including roads, bridges, and buildings, are boosting the requirement for construction adhesives. Additionally, the packaging sector in Latin America is expanding rapidly, fueled by the development of e-commerce and consumer goods. These resins are essential for packaging applications, including labeling, sealing, and bonding. The furniture sector in the region is experiencing development, especially in countries like Brazil Adhesive resins are used in various furniture manufacturing processes, such as wood bonding and upholstery. Thus, as per the adhesive resin market analysis, as Latin America continues to industrialize and urbanize, the demand for these resins is expected to grow steadily.

Top Key Players and Market Share Insights:

The Adhesive Resin market is highly competitive with major players providing precise products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Adhesive Resin market. Key players in the Adhesive Resin industry include-

- BASF (Germany)

- Dow (U.S.)

- Evonik Industries AG (Germany)

- NIPPON SHOKUBAI CO., LTD. (Japan)

- Sumitomo Bakelite Co. (Japan)

- DIC CORPORATION (Japan)

- Eastman Chemical Company (U.S.)

- Mitsubishi Chemical Group Corporation (Japan)

- SABIC (Saudi Arabia)

- Sinochem (China)

Recent Industry Developments :

Product Launch:

- In November 2023, EPS: Engineered Polymer Solutions launched EPS 2133, an all-acrylic polymer made without APEO (Alkylphenol Ethoxylates) surfactants that can be formulated for permanent and removable pressure-sensitive adhesive applications.

- In June 2023, DIC Corporation announced the launch of the HYDRAN GP series of waterborne polyurethane resins. The new resins have a higher solid content than conventional water-based polyurethane resins and contain no amines, helping customers to shorten process times and lessen odors, as well as reduce greenhouse gas emissions and volatile organic compounds. The company has planned to promote this series globally for applications such as adhesives.

Adhesive Resin Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 25,170.81 Million |

| CAGR (2025-2032) | 4.8% |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Adhesive Resin market? +

In 2024, the Adhesive Resin market is USD 17,445.37 Million.

Which is the fastest-growing region in the Adhesive Resin market? +

North America is the fastest-growing region in the Adhesive Resin market.

What specific segmentation details are covered in the Adhesive Resin market? +

Type and Application segmentation details are covered in the Adhesive Resin market.

Who are the major players in the Adhesive Resin market? +

BASF, SABIC, and Dow are some of the major players in the market.