- Summary

- Table Of Content

- Methodology

Adhesive Equipment Market Size:

Adhesive Equipment Market size is growing with a CAGR of 5.3% during the forecast period (2024-2031), and the market is projected to be valued at USD 20,682.13 Million by 2031 from USD 13,755.00 Million in 2023.

Adhesive Equipment Market Scope & Overview:

Adhesive equipment refers to tools and machinery used in the application, dispensing, and bonding of adhesives in various sectors. These systems are essential for automating the adhesive application process, improving consistency, and speed, and reducing waste. There are different types of equipment. Dispensing systems control the precise application of adhesives. Curing systems are used to solidify adhesives, such as UV or heat curing equipment. Mixing equipment is used for two-part adhesives that require mixing before application. These adhesive application equipment offers several advantages, such as improved precision, reduced labor costs, and enhanced production efficiency. It also ensures consistent adhesive bonding, which is critical in sectors such as automotive, electronics, packaging, and construction. Moreover, modern systems are designed to minimize material wastage, ensuring cost-effectiveness while maintaining high bonding quality and speed in manufacturing processes.

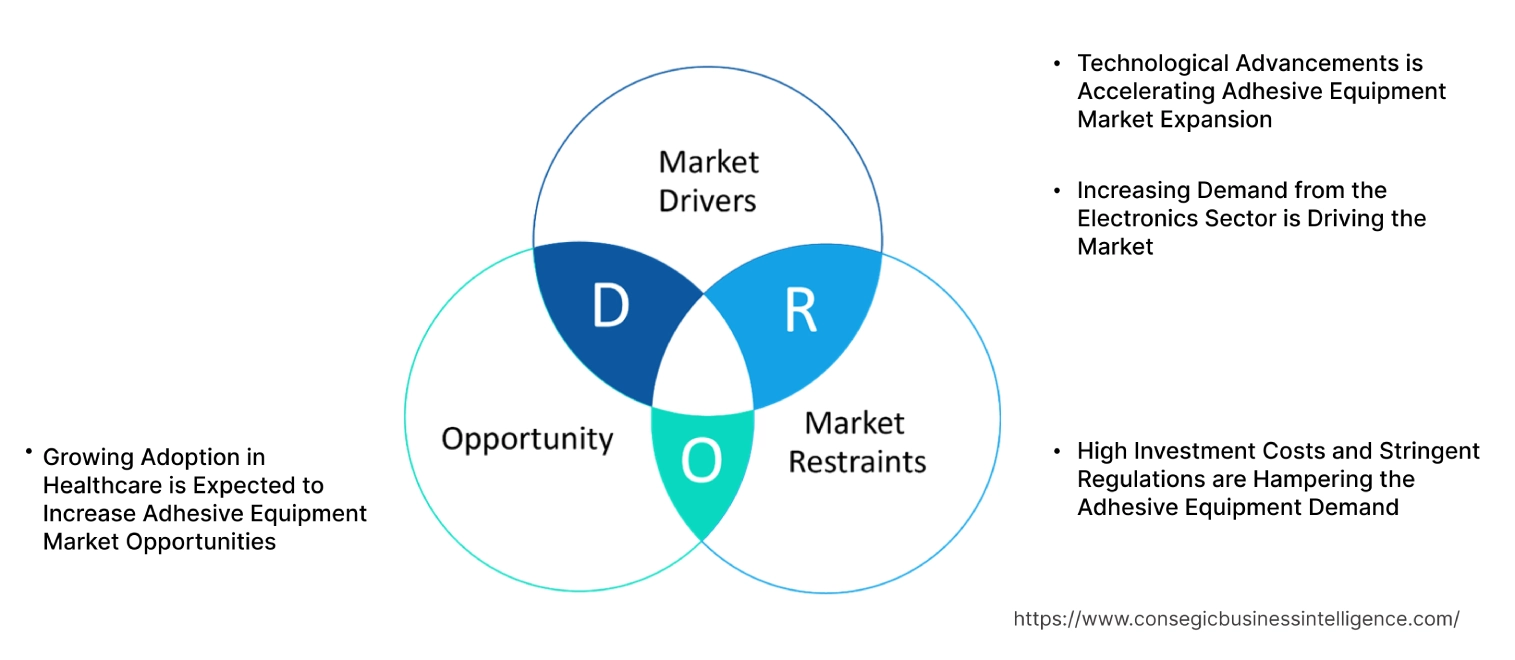

Key Drivers:

Technological Advancements is Accelerating Adhesive Equipment Market Expansion

The market is continuously evolving, driven by technological advancements that enhance precision, efficiency, and sustainability. One key innovation is the integration of robots with precise dispensing systems that enable automated and flexible application of adhesives, improving accuracy and reducing labor costs. Moreover, meter, mix, and dispense (MMD) systems ensure accurate and consistent mixing of multi-component adhesives, optimizing performance and reducing waste.

Additionally, sensors integrated into adhesive equipment allow for real-time monitoring of parameters such as temperature, pressure, and flow rate, enabling predictive maintenance and optimizing performance. Furthermore, there is the development of adhesive dispensing systems, specific to sectors. This ensures precise dosing, especially in high-volume sectors. Manufacturers are introducing advanced dispensing systems with improved precision, speed, and efficiency.

- For instance, in March 2022, Techcon launched their innovative TS9800 Series Jet Valve Dispensing System. This system serves as an ideal solution for machine integrators and builders seeking to dispense ultra-small amounts of adhesives and fluids with efficiency and consistency to fulfill high-production and premium-quality standards. Thus, these innovations are meeting the increasing need for miniaturization and high-precision assembly in sectors, influencing the adhesive equipment market growth.

Overall, the continuous technological advancements in adhesive dispensing systems, coupled with the increasing need for precision and efficiency are significantly boosting the adhesive equipment market expansion.

Increasing Demand from the Electronics Sector is Driving the Market

The electronics sector is a major driver of the market. This equipment plays a crucial role in electronics by enabling precise, efficient, and reliable bonding of components. Its primary purpose is to ensure structural integrity, electrical insulation, and thermal management in electronic devices.

As electronic products become increasingly compact and complex, adhesive application equipment provides the accuracy needed to apply adhesives in small, intricate areas where traditional fasteners are impractical. In device assembly, adhesive application equipment facilitates the bonding of components such as circuit boards, displays, batteries, and sensors. It ensures uniform application, minimizing waste and defects while enhancing product durability and performance. Globally there is an increasing need for consumer electronics such as smartphones and laptops.

- For instance, according to Canalys, a global technology firm, the Indian personal computer market (which encompasses desktops, notebooks, and tablets) experienced a 4% year-over-year growth in Q4 2023, with a total of 4.3 million units sold. The manufacturing of these devices requires precise and efficient adhesive application for assembling components thus influencing global adhesive market trends positively.

Overall, the increasing need for electronic devices, coupled with the need for precise and efficient assembly techniques, is driving the global adhesive equipment market growth.

Key Restraints :

High Investment Costs and Stringent Regulations are Hampering the Adhesive Equipment Demand

The high initial capital investment required for advanced adhesive application equipment, including automated systems, precision machinery, and specialized tools, limits market entry for smaller businesses or those with limited budgets. This upfront expenditure, along with ongoing maintenance and operational costs, deters companies from upgrading or expanding their capabilities, especially in cost-sensitive sectors.

In addition, stringent regulations related to safety, environmental standards, and product quality further complicate the market share. Manufacturers of these equipment must comply with various local and international regulations, such as those governing emissions, material safety, and waste disposal. These compliance requirements necessitate investments in additional technology, certifications, and processes, adding to the overall cost burden, and further hindering adhesive equipment market trends. The complexity of adhering to these regulations delays product launches, increases lead times, and creates barriers for companies trying to enter new markets or expand operations.

Overall, high initial investment, stringent regulations, and complex operational requirements are significant barriers hindering the adhesive equipment market demand.

Future Opportunities :

Growing Adoption in Healthcare is Expected to Increase Adhesive Equipment Market Opportunities

Adhesive application equipment in healthcare is essential for bonding materials used in medical devices, wound care, and surgical applications. In wound care, this equipment is used for products such as bandages, dressings, and medical tapes, providing secure adhesion to the skin while allowing for flexibility and comfort. The precision of equipment ensures controlled application, which is crucial for patient safety, minimizing irritation, and promoting healing.

In medical devices, it is utilized to assemble components such as catheters, electrodes, and diagnostic strips, ensuring precise, secure, and durable attachments. The equipment allows for the application of pressure-sensitive adhesives (PSA) and heat-activated adhesives in the assembly of these devices without compromising their functionality. The increasing prevalence of chronic diseases, aging populations, rising healthcare expenditure, and technological advancements have led to an increase in the need for medical devices.

- For instance, according to the International Trade Administration, the medical device market in China is projected to grow at a compound annual growth rate (CAGR) of 8.3% from 2021 to 2026. The manufacturing of medical devices requires precise and reliable bonding of components, which is achieved effectively through the use of advanced equipment, thus creating the potential for the market.

Overall, expansion in the healthcare sector and the increasing need for medical devices are expected to increase adhesive equipment market opportunities.

Adhesive Equipment Market Segmental Analysis :

By Type:

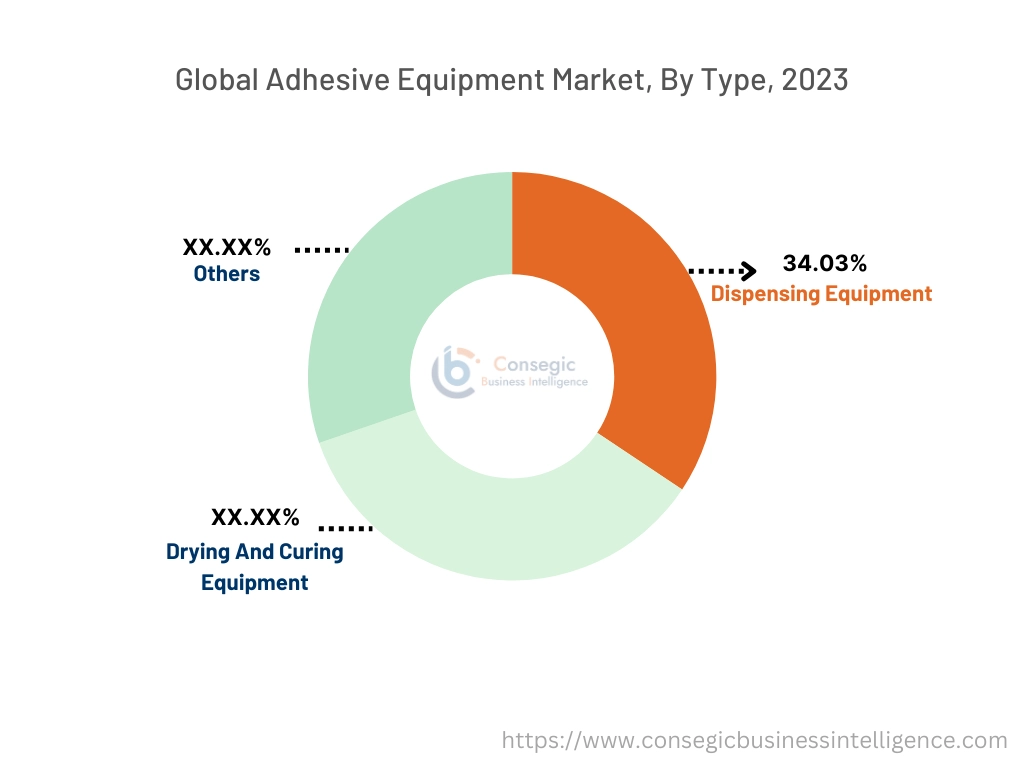

Based on type, the market is categorized into dispensing equipment, drying and curing equipment, and others.

Trends in the Type:

- Growing focuses on rapid curing and energy-efficient drying solutions.

- Integration of robotics and automation technologies for enhanced productivity and accuracy.

The dispensing equipment segment accounted for the largest market share of 34.03% in 2023.

- Dispensing systems are essential tools in various sectors for precise and efficient application of adhesives. These systems ensure accurate dosing, consistent application, and optimal performance.

- Pneumatic systems offer high-volume, high-speed dispensing, while electric systems provide precise control for intricate applications. Time-temperature systems are ideal for two-component adhesives, ensuring accurate mixing and curing. Hot melt systems offer rapid bonding and high-strength joints for packaging and manufacturing applications. These systems enhance productivity, reduce waste, and improve product quality.

- For instance, in November 2022, Techcon launched the innovative TS8200D series micro-meter mix dispensing system, a highly accurate volumetric mixing and dispensing solution for two-component adhesives, including epoxies, reactive acrylics, and polyurethanes. These new products cater to the evolving needs of various sectors, including electronics, automotive, healthcare, and packaging, driving the segment.

- Overall, as per the analysis, the development of new dispensing systems catering to different sectors' needs is driving the segment.

The drying and curing segment is expected to grow at the fastest CAGR over the forecast period.

- Drying and curing equipment plays a crucial role in the adhesive application process by solidifying or stabilizing adhesives after they are applied to the surface. This equipment ensures the adhesive bonds properly and achieves its desired strength, durability, and performance. It is widely used in sectors such as automotive, electronics, aerospace, and packaging, where the precision and reliability of adhesive bonding are critical.

- Heat curing systems utilize heat to accelerate the curing of adhesives such as epoxies or thermoset resins, commonly used in industrial and automotive applications.

- Infrared curing systems use infrared radiation to heat adhesives, offering fast and uniform curing, particularly for large surfaces.

- As per the market analysis, the segment for the upcoming years is driven by the stringent regulatory standards for product safety and durability, the need for rapid production cycles, and the growing focus on energy efficiency.

By End-Use Industry:

The end-use industry segment is categorized into packaging, construction, automotive, electronics, healthcare, and others.

Trends in End-Use Industry:

- Advancements in automotive manufacturing necessitate precise and reliable adhesive application equipment.

- The increase in e-commerce has fueled the need for reliable and efficient packaging solutions, including adhesive application equipment for box sealing and labeling.

The packaging segment accounted for the largest market share in 2023.

- Equipment used for adhesive applications is essential in the packaging sector for ensuring secure, efficient, and high-quality bonding of materials used in various applications such as carton sealing, labeling, and flexible packaging.

- These systems enable the precise application of adhesives, ensuring the durability and integrity of packaging under different conditions, including transportation and storage. They also support fast and scalable production processes, which are critical in high-requirement sectors such as food, beverages, pharmaceuticals, and e-commerce.

- Automated equipment significantly accelerates packaging lines by applying adhesives quickly and consistently, reducing production time and labor costs. These systems ensure precise adhesive application, minimizing material waste and lowering operational costs.

- Increasing global trade and growing consumer requirements for convenience and product protection have led to an increase in packaging solutions.

- According to Metsa Group, a sustainable products manufacturing company, the anticipated yearly growth rate of the packaging sector for the period of 2023–2028 is projected to be approximately 4%. This is driving the segment as the packaging sector heavily relies on adhesive application equipment for various applications, such as sealing, labeling, and bonding.

- Overall, the analysis indicates that the increasing requirements for packaging solutions are driving the segment in the adhesive equipment industry.

The construction segment is expected to grow at the fastest CAGR over the forecast period.

- Adhesive application equipment is critical in the construction sector, enabling the efficient application of bonding materials for various tasks such as flooring installation, insulation bonding, panel assembly, and structural repairs.

- These systems ensure precise adhesive distribution, improving the durability, stability, and quality of construction projects. With advancements in adhesive technologies, such equipment is increasingly used for sustainable and lightweight construction materials.

- Additionally, this equipment handles various adhesive types, including polyurethane, epoxy, and silicone, making it suitable for a wide range of materials such as wood, concrete, glass, and metal.

- Proper adhesive application enhances resistance to environmental factors such as moisture, temperature fluctuations, and vibration.

- According to market analysis, urbanization, population increase, government infrastructure investments, economic growth, and the increasing need for housing and commercial spaces have led to construction sector progress, boosting the segmental trend in the adhesive equipment market.

Regional Analysis:

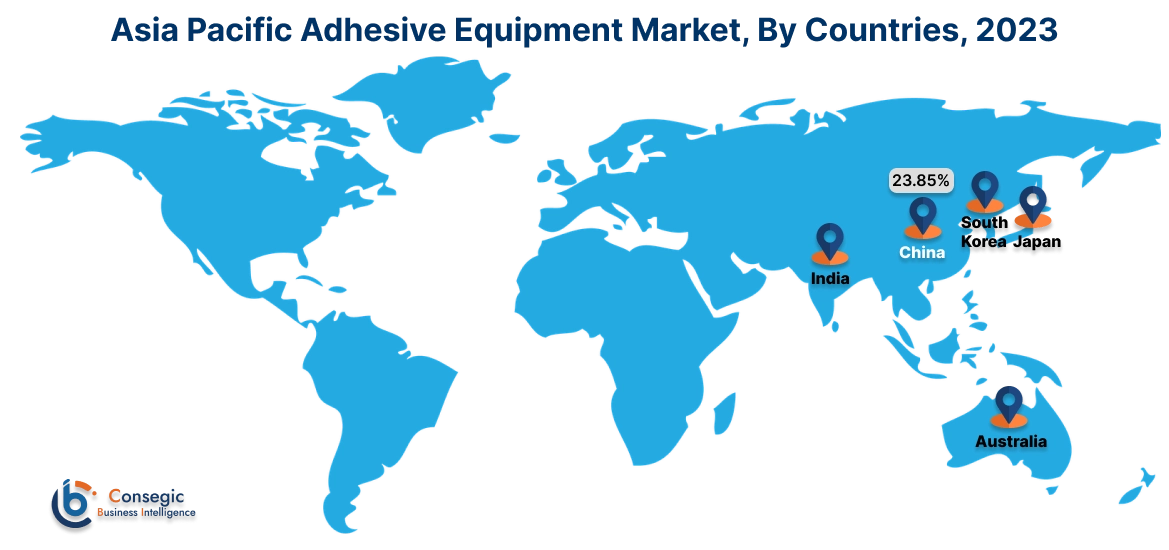

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

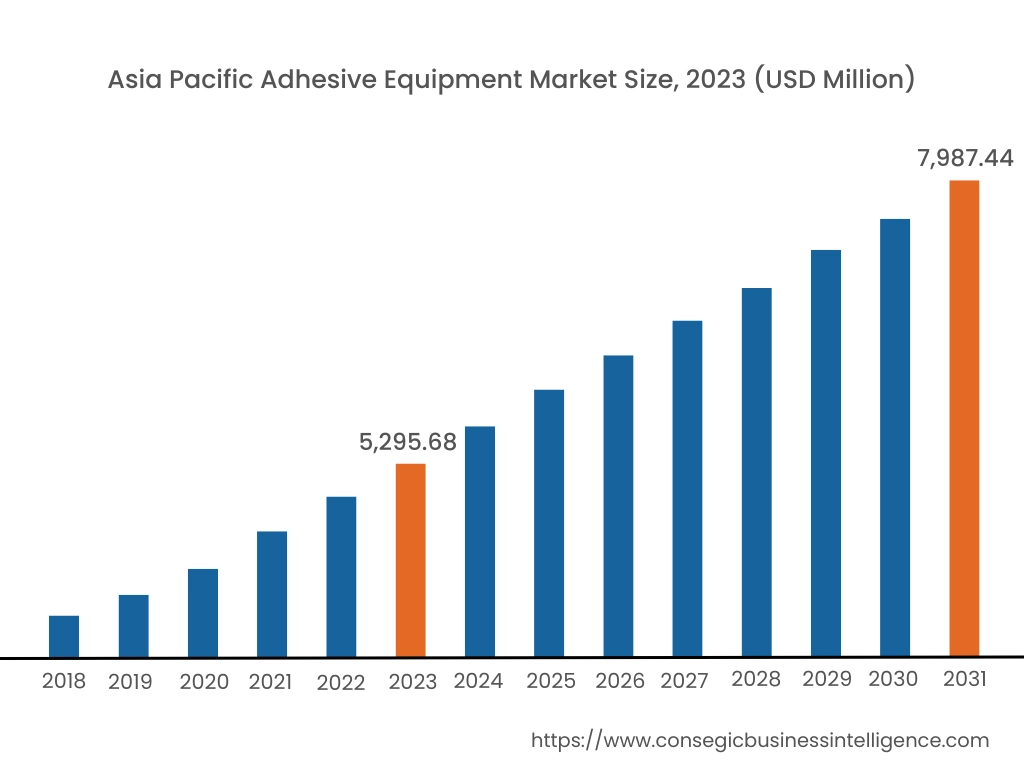

In 2023, Asia Pacific accounted for the highest adhesive equipment market share at 38.50% and was valued at USD 5,295.68 Million and is expected to reach USD 7,987.44 Million in 2031. In Asia Pacific, China accounted for the highest adhesive equipment market share of 23.85% during the base year of 2023. The dominance is driven by several key trends. There is an increasing need due to rapid industrialization, a robust manufacturing base, and growing end-user sectors. Key sectors such as automotive, construction, electronics, packaging, and textiles in countries such as China, India, Japan, and South Korea are driving the need for adhesive application systems. APAC’s manufacturing hubs benefit from low labor costs, favorable government policies, and substantial foreign direct investment, further strengthening the market. Moreover, China leads the region with its extensive production of electronics, automobiles, and consumer goods, necessitating advanced adhesive technologies. India’s booming construction and automotive sectors are also contributing to local adhesive equipment manufacturing to cater to the need.

- For instance, the Indian company 1K2K Dosing and Dispensing introduced its brand “ADoST” in January 2023. The “ADoST” dispensing systems are crafted to resonate with all manufacturers who prioritize minimizing waste generation and reducing high adhesive application expenses.

Overall, the Asia-Pacific region's dominance in the global adhesive equipment market is primarily driven by rapid industrialization, robust manufacturing, and increasing requirements from key sectors such as automotive, construction, and electronics, coupled with favorable government policies and cost-effective manufacturing.

In North America, the adhesive equipment market is experiencing the fastest growth with a CAGR of 5.9% over the forecast period. The region's mature automotive and aerospace sectors are driving the need for precision adhesive application systems, particularly for lightweight and structural bonding. Additionally, the packaging sector, bolstered by the rise in e-commerce, is a significant contributor, with an increased need for automated adhesive dispensing solutions. Moreover, the construction sector is another driver, as rising infrastructure investments in the U.S. and Canada fuel the need for adhesive equipment in applications such as flooring, panel assembly, and insulation. Furthermore, North America is also seeing growing adoption of eco-friendly adhesives and equipment, aligning with stringent environmental regulations and corporate sustainability goals.

Europe's adhesive equipment market analysis states several trends are responsible for the progress of the market in the region. Investments in research and development have enabled innovations in adhesive equipment, such as robotic dispensing systems and smart monitoring technologies, which improve efficiency and reduce waste. Moreover, other drivers include the automotive sector's push toward electric vehicles (EVs), where adhesives are critical for battery assembly, lightweight, and noise reduction. Germany, as a hub for automotive innovation, plays a significant role. Additionally, the region’s robust construction sector, driven by green building initiatives and infrastructure modernization, also fuels the need for advanced adhesive application systems.

The Middle East and Africa (MEA) adhesive equipment market analysis states that the region is also witnessing a notable surge in the market. Extensive infrastructure projects, particularly in construction and transportation, are driving the market in the region. Moreover, the increasing focus on lightweight and automation in manufacturing further fuels demand. Additionally, the trend of the rising demand for packaged goods, especially in food and beverage, pharmaceuticals, and consumer goods, is driving the adoption of high-speed and precise adhesive application equipment. Furthermore, countries such as Saudi Arabia, UAE, and Egypt are emerging as significant markets for equipment due to their economic increase and increasing industrial activity.

Latin America's adhesive equipment market size is also emerging. Countries such as Brazil, Mexico, and Argentina are experiencing robust industrial activity increases, particularly in sectors such as aerospace, and electronics. This surge in manufacturing activities necessitates advanced adhesive application equipment for efficient production processes. Moreover, the growing packaging sector, especially in the food and beverage sector, is fueling the demand for packaging adhesives and application equipment. Additionally, the automotive sector in Latin America is witnessing a significant increase, with increasing production of vehicles, further influencing the market. Economic fluctuations and political instability in certain countries impact the market.

Adhesive Equipment Market Competitive Landscape:

The adhesive equipment market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global adhesive equipment market. Key players in the Adhesive equipment industry include-

- 3M (U.S.)

- Graco (U.S.)

- Robatech Group (Switzerland)

- Valco Melton (U.S.)

- Glue Machinery Corporation (U.S.)

- Nordson Corporation (U.S.)

- Henkel AG (Germany)

- Techcon (U.S.)

- Dymax Corporation (U.S.)

- ITW Dynatec (U.S.)

Recent Industry Developments :

Product Launch:

- In March 2022, Techcon Introduces the Latest TS9800 Series Jet Valve Dispensing System for Manufacturing Electronic and Medical Devices. The TS9800 Jet Valve dispensing system serves as an ideal choice for integrators and manufacturers of electronic and medical devices that require the efficient and consistent dispensing of ultra-small quantities of adhesives and fluids to fulfill demanding production and quality standards.

Adhesive Equipment Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 20,682.13 Million |

| CAGR (2024-2031) | 5.3% |

| By Type |

|

| By End-use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Adhesive Equipment market? +

In 2023, the Adhesive Equipment market is USD 13,755.00 Million.

Which is the fastest-growing region in the Adhesive Equipment market? +

North America is the fastest-growing region in the Adhesive Equipment market.

What specific segmentation details are covered in the Adhesive Equipment market? +

Type and End-Use Industry segmentation details are covered in the Adhesive Equipment market

Who are the major players in the Adhesive Equipment market? +

3M (U.S.), Graco (U.S.), Nordson Corporation (U.S.), Henkel AG (Germany), Techcon (U.S.), Dymax Corporation (U.S.), ITW Dynatec (U.S.), Robatech Group (Switzerland), Valco Melton (U.S.), and Glue Machinery Corporation (U.S.).