- Summary

- Table Of Content

- Methodology

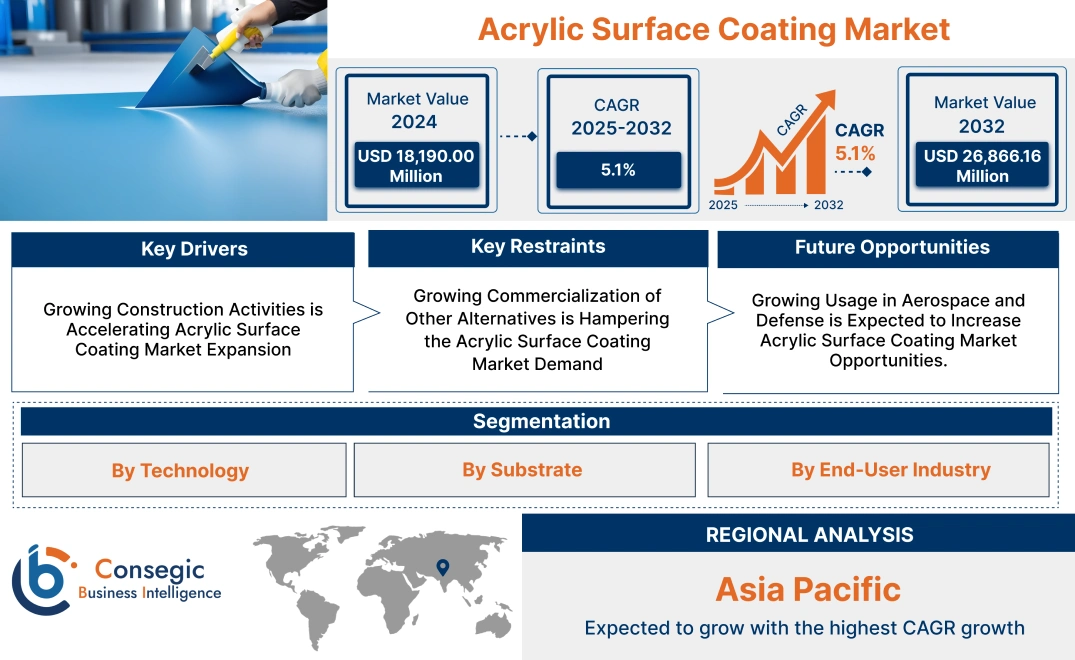

Acrylic Surface Coating Market Size:

Acrylic Surface Coating Market size is growing with a CAGR of 5.1% during the forecast period (2025-2032), and the market is projected to be valued at USD 26,866.16 Million by 2032 from USD 18,190.00 Million in 2024.

Acrylic Surface Coating Market Scope & Overview:

Acrylic surface coatings are protective layers made from acrylic polymers that are applied to surfaces to enhance their durability and appearance. These coatings withstand prolonged exposure to outdoor elements such as sunlight, rain, and temperature fluctuations due to their good UV resistance and long-term flexibility. They readily adhere to a variety of surfaces such as metal, concrete, and plastic, providing a strong bond. They are also resistant to moisture, mildew, and chemical damage.

Additionally, they are known for their ease of application and quick drying time. Furthermore, they are formulated to achieve a smooth, glossy, or matte finish depending on the desired aesthetic. Also, these coatings are typically easy to apply using various methods such as brushing, rolling, or spraying. These coatings are widely used in interior and exterior paints, automotive finishes, industrial coatings for machinery and equipment, and marine coatings. Their versatility and superior performance make them a popular choice for various surface protection and decorative needs.

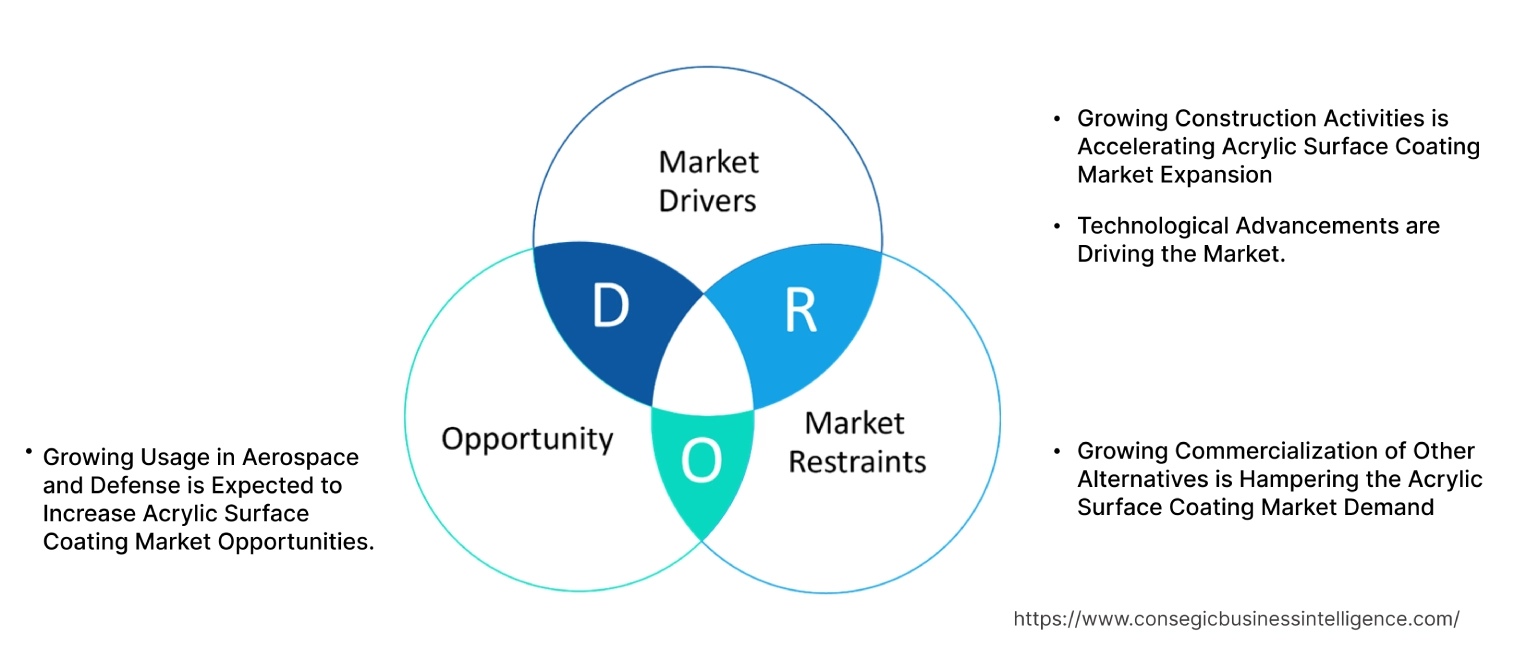

Key Drivers:

Growing Construction Activities is Accelerating Acrylic Surface Coating Market Expansion

In construction, these coatings are commonly used to protect and enhance various surfaces. It offers benefits such as weather resistance, flexibility, and durability against UV rays and moisture, making them ideal for both interior and exterior applications in residential and commercial buildings. They are used on concrete floors, walls, roofs, foundations, pool decks, and more, depending on the specific formulation. Moreover, acrylic coatings retain their color well when exposed to outdoor elements. Additionally, they are relatively inexpensive when compared to other coating, making it a cost-efficient option for bigger infrastructure projects.

Government initiatives such as infrastructure development projects and affordable housing schemes have boosted the construction sector. Additionally, rising urbanization and population growth have increased the requirements for commercial spaces and housing.

- According to an article published by JLL India, a leading global real estate services company, India recorded its highest residential sales ever in Q2 2024, reaching 80,345 units, reflecting a year-on-year growth of 5%. As more construction projects commence, the need for acrylic coating for floors, walls, and roof applications has increased, positively influencing the market.

Overall, the surge in construction activity, driven by factors such as government initiatives, urbanization, and increasing residential sales, is significantly boosting the acrylic surface coating market expansion.

Technological Advancements are Driving the Market.

Recent technological advancements have significantly enhanced the performance, sustainability, and versatility of acrylic coatings. Nanotechnology is a key innovation, enabling the development of coatings with superior scratch resistance, and UV protection properties. These coatings are increasingly used in automotive, construction, and industrial applications due to their enhanced durability.

Moreover, innovative polymer chemistries have led to the development of coatings with superior properties, such as self-cleaning, anti-graffiti, and anti-microbial functionalities. Additionally, another key innovation includes UV-curable acrylic coatings for superior performance and improved adhesion to diverse substrates. Additionally, manufacturers are focusing on developing coating with unique combinations providing high performance to the end-use sector.

- For instance, in March 2023, Gaco introduced GacoFlex A48, a single-component, high-build acrylic roof coating. This innovative product offers numerous benefits, including rapid curing, excellent durability, and superior reflectivity. It is the first and only single component that is applied up to 80 wet mils (5 gal/SQ) in a single pass application. These product innovations have expanded acrylic coating reach in multiple sectors, positively influencing acrylic surface coating market trends.

Overall, technological advancements and innovative product introductions are playing a crucial role in accelerating the global acrylic surface coating market growth.

Key Restraints :

Growing Commercialization of Other Alternatives is Hampering the Acrylic Surface Coating Market Demand

The market faces significant restraint from competition posed by alternative coating technologies, such as polyurethane, epoxy, and fluoropolymer coatings. These alternatives provide superior performance characteristics, such as enhanced chemical resistance, better durability in harsh environments, and stronger adhesion properties.

Polyurethane coatings, for instance, are widely preferred in sectors such as automotive and construction due to their excellent wear resistance and flexibility. Similarly, epoxy coatings dominate applications requiring high mechanical strength and superior corrosion resistance, such as industrial equipment.

Additionally, these alternatives offer customization options, such as higher UV resistance or faster curing times, making them attractive for specific niche applications where acrylic coatings fall short, further hindering acrylic surface coating market trends. This increasing preference for high-performance alternatives limits the market share and potential of acrylic surface coatings, forcing manufacturers to innovate and enhance their product offerings to remain competitive.

Overall, analysis shows that the intense competition from alternative coatings with superior performance characteristics poses a significant restraint on the market, hampering the acrylic surface coating market demand.

Future Opportunities :

Growing Usage in Aerospace and Defense is Expected to Increase Acrylic Surface Coating Market Opportunities.

In aerospace, acrylic coatings are primarily used as conformal coatings to protect sensitive electronic components within aircraft from harsh environmental conditions such as humidity, temperature fluctuations, and corrosive elements. This prevents moisture build-up on circuit boards, ensuring reliable operation in extreme environments. Moreover, they are applied to smaller aircraft and components where flexibility and ease of repair are needed.

Additionally, acrylic coatings are also used in cockpit displays and instrument panels due to their optical clarity and resistance to scratching. Furthermore, these coatings are applied to aircraft exteriors, interiors, and military equipment such as tanks, drones, and naval vessels. These coatings are easy to apply and maintain, reducing downtime for repairs.

Increasing global air travel adoption, rising geopolitical tensions necessitating military modernization, advancements in aerospace technology, and growing space exploration activities are driving the growth of the aerospace and defense sector.

- For instance, according to Spartronics, an electronic and electromechanical devices manufacturer for commercial aerospace, the U.S. Aerospace & Defense market is projected to grow at a robust pace of 8.5% annually from 2022 to 2026. This drives the need for acrylic coating to enhance the durability, corrosion resistance, and overall performance of critical aerospace components, creating potential for the upcoming years.

Overall, the development in the aerospace and defense sector requiring coating for various purposes is expected to increase acrylic surface coating market opportunities.

Acrylic Surface Coating Market Segmental Analysis :

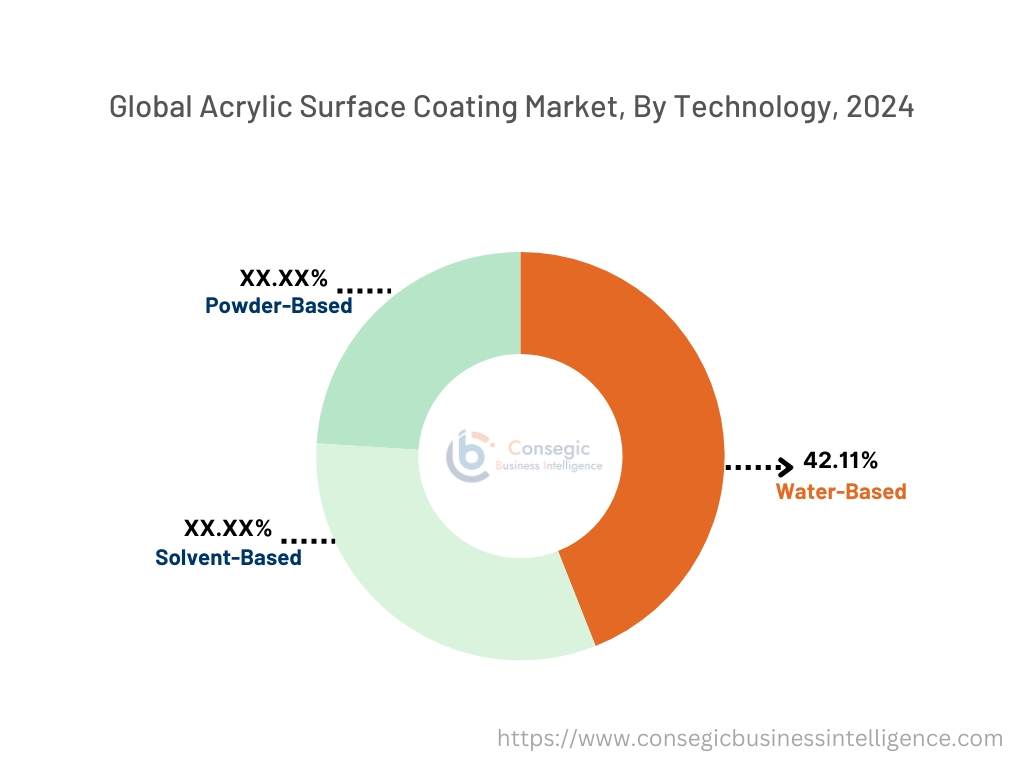

By Technology:

Based on technology, the market is categorized into water-based, solvent-based, and powder-based.

Trends in Technology:

- Increasing focus on sustainable and eco-friendly water-based coatings.

- Growing adoption of UV-curable acrylic coatings for rapid curing, high gloss, and excellent durability.

The water-based segment accounted for the largest market share of 42.11% in 2024.

- Water-based acrylic coatings are a type of paint or coating that uses water as its primary solvent, rather than organic solvents. This makes them safer to use than solvent-based coatings.

- Water-based acrylic coatings emit fewer volatile organic compounds (VOCs), which are harmful to both human health and the environment. As water is non-flammable, these coatings pose a lower fire risk compared to solvent-based options. Moreover, water-based coatings dry more quickly, reducing application time and improving efficiency.

- Additionally, water-based coatings are easily cleaned up with soap and water, eliminating the need for harsh chemical solvents. Furthermore, water-based coatings have significantly lower odor emissions, making them more pleasant to work with in indoor environments. There is rapid urbanization resulting in a surge in infrastructure projects.

- For instance, in 2023, the S. federal government spent USD 44.8 billion on overall infrastructure and transferred USD 81.5 billion to states such as Texas, and New York amongst others. This has positively impacted the segment, as they are widely used in various infrastructure projects due to their excellent weather resistance, durability, and aesthetic appeal.

- Overall, there is an increasing need for water-based acrylic coating, driven by rising infrastructure projects, as they have an eco-friendly nature, rapid drying times, and ease of application, thus driving the segment.

The powder-based segment is expected to grow at the fastest CAGR over the forecast period.

- Powder-based acrylic coatings are a type of dry coating that is applied as a fine powder. This powder is electrostatically charged and sprayed onto a grounded metal surface. When heated, the powder melts and fuses together, forming a durable and protective coating.

- This protective layer is known for its excellent weatherability, smoothness, gloss, and resistance to chemicals and UV damage; used as a clear coat finish on various products such as automotive parts or outdoor furniture.

- Moreover, powder coating has high transfer efficiency, meaning less material waste compared to liquid coatings.

- Additionally, powder coatings are applied to a wide range of substrates, including metals, plastics, and composites.

- As per the market analysis, the segment of powder-based acrylic coating for the upcoming years is driven by the increasing requirements for durable and long-lasting finishes across various sectors, such as automotive, construction, and furniture. Advancements in powder coating technology further boost the segment.

By Substrate:

The substrate segment is categorized into metal, wood, plastic, concrete, and others.

Trends in the Substrate:

- Rising need for concrete coatings to improve durability, water resistance, and appearance of concrete structures.

- Focus on the development of protective and decorative coatings for plastic substrates.

The metal segment accounted for the largest market share in 2024.

- Metal substrates dominate the acrylic surface coating market growth due to their widespread use in various sectors.

- Acrylic coatings are used for automotive body panels, wheels, and other components. Moreover, acrylic coatings are used on appliances to improve their appearance, protect against scratches, and enhance their cleaning properties. Additionally, it is applied to metal structures such as bridges, buildings, and industrial equipment.

- These coatings adhere well to metal surfaces, providing a strong bond and long-lasting protection. They form a protective barrier that prevents corrosion, extending the life of metal components.

- A robust global economy, rising disposable incomes, and advancements in automotive technology, such as electric and autonomous vehicles have contributed to an increase in the automotive sector.

- For instance, according to the European Commission, the year 2022 marked a pivotal moment for the growth of electric vehicles in Germany. As of January 1, 2022, there were 618,460 registered electric cars, reflecting a remarkable 100% increase from the start of 2021. This has led to increased requirements for specialized coatings for metal parts of vehicles that offer corrosion protection and aesthetic appeal, thus driving the segment in the market.

- Overall, as per the market analysis, the automotive sector’s increase, particularly in electric vehicles, is driving this segment in the acrylic surface coating industry.

The plastic segment is expected to grow at the fastest CAGR over the forecast period.

- Acrylic coatings are increasingly finding applications on various plastic substrates. One prominent example is in the automotive sector, where they are used to coat plastic components such as bumpers, spoilers, and interior trims.

- Acrylic coatings provide excellent resistance to scratches, chips, and UV radiation, helping to maintain the appearance and functionality of plastic components.

- They offer superior resistance to fading, chalking, and weathering, ensuring long-lasting performance even in harsh outdoor conditions.

- They are formulated to achieve a wide range of finishes, from high gloss to matte, and are customized to meet specific performance requirements.

- The increasing need for lightweight and flexible electronic devices, and the automotive sector’s shift towards lightweight and electrification, create potential for the segment in the upcoming years.

By End-Use Industry:

The end-use industry segment is categorized into construction, automotive, aerospace & defense, marine, and others.

Trends in End-Use Industry

- Increasing need for fouling-release coatings in marine.

- Growing utilization of acrylic coatings to improve the aesthetics and protective properties of packaging materials.

The construction segment accounted for the largest market share in 2024.

- Acrylic coatings are widely used on various surfaces such as walls, ceilings, roofs, and exterior facades. They are also applied to concrete, masonry, and metal surfaces for protection and aesthetic enhancement.

- They provide a strong barrier against rain, snow, and other weather elements, protecting structures from water damage and extending their lifespan.

- They are also highly resistant to UV radiation, preventing color fading and degradation from sunlight exposure.Moreover, they are used in sealing concrete surfaces to prevent moisture penetration and cracking.

- Increasing population and rapid urbanization have led to the need for robust infrastructure, such as roads, bridges, and transportation systems.

- For instance, according to the Office for National Statistics, in 2022, the total value of new work infrastructure construction saw an 11.2% rise when compared to 2021. This drives the need for acrylic protective coating for various construction applications such as bridges, thus driving a segment in the market.

- Overall, increasing infrastructure investments, driven by urbanization and industrialization are driving the segment.

The automotive segment is expected to grow at the fastest CAGR over the forecast period.

- Acrylic surface coatings are widely used in the automotive sector, primarily for painting vehicle bodies and components. They are applied to various surfaces such as steel, aluminum, and plastic.

- Acrylic coatings last over 10 years with proper maintenance. Moreover, they are resistant to chemicals, UV rays, and weathering. They are also acid and alkali corrosion-resistant, and grease-resistant. In automotive, these coatings are a cost-effective and efficient choice.

- Additionally, acrylic conformal coating helps maintain the reliability of control units and sensors in automotive electronics. Also, they retain their original color and gloss over time, ensuring a long-lasting, vibrant finish.

- Furthermore, these coatings accommodate the thermal expansion and contraction of vehicle components, preventing cracking and peeling.

- According to the market analysis, the growing middle class with increased purchasing power fuels the need for personal vehicles, boosting the segmental trend in the year forecasted.

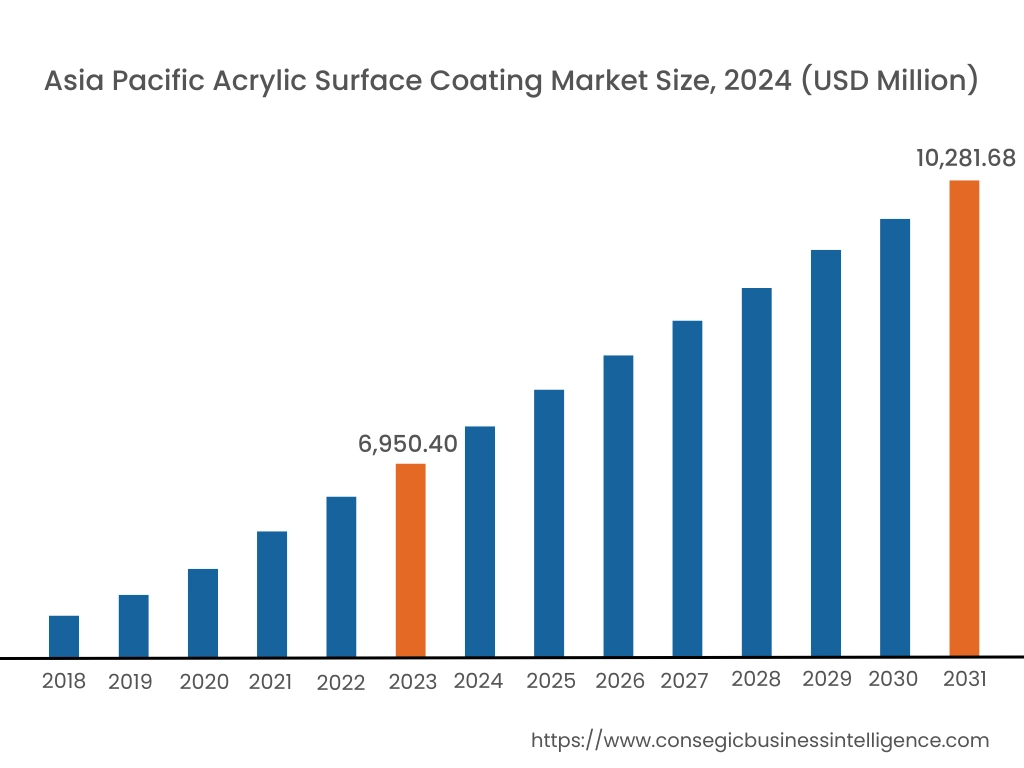

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

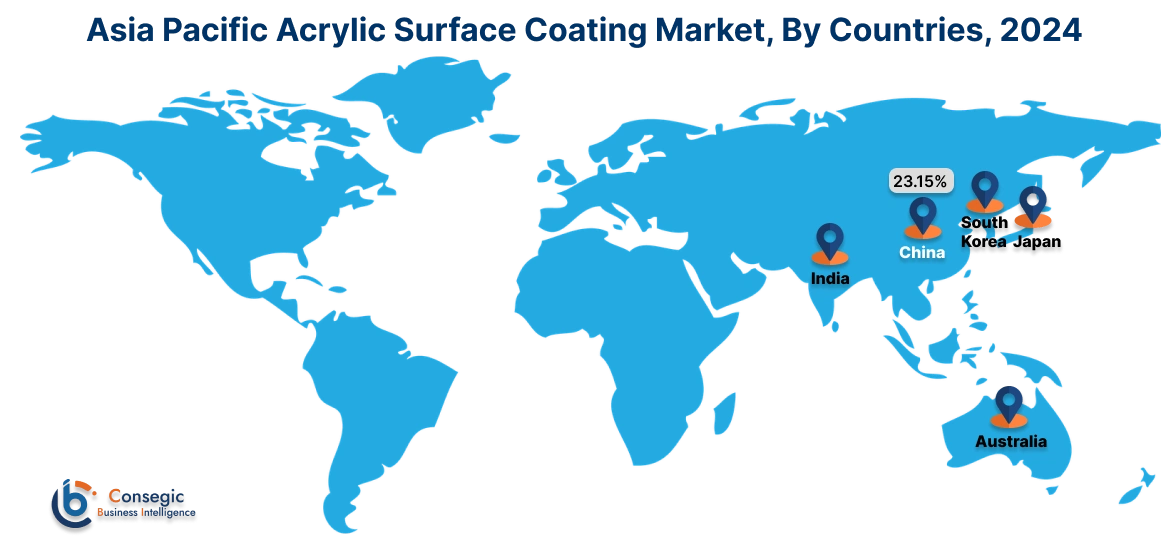

In 2024, Asia Pacific accounted for the highest acrylic surface coating market share at 38.21% and was valued at USD 6,950.40 Million and is expected to reach USD 10,281.68 Million in 2032. In Asia Pacific, China accounted for the highest acrylic surface coating market share of 23.15% during the base year of 2024. The region is witnessing rapid urbanization and infrastructure development, leading to increased requirements for the construction of acrylic coatings. Moreover, the automotive sector in APAC, particularly in countries such as China, Japan, and India, is experiencing a significant surge.

- For instance, according to MarkLines Co, an advertising agency company, production levels of passenger cars in Japan for November 2023 rose by 12.8% year-on-year to reach 819,373 units. Additionally, export figures for November saw an increase of 8.7% year-on-year, totaling 381,087 units. This drives the need for high-quality, durable, and aesthetically appealing acrylic coatings.

Additionally, the rising disposable income in many APAC countries is fueling the need for premium-quality paints and coatings, including acrylic-based products. Furthermore, APAC offers cost-effective manufacturing capabilities such as low labor cost and supply chain efficiency, making it an attractive region for acrylic coating production and export. Overall, the combination of rapid urbanization, a booming automotive sector, rising disposable incomes, and cost-effective manufacturing has solidified APAC's dominance in the global acrylic surface coating market.

In North America, the acrylic surface coating market is experiencing the fastest growth with a CAGR of 5.6% over the forecast period. The market is driven by multiple trends. The region is home to major key players such as PPG, Sherwin-Williams, and Axalta Coating Systems. Moreover, the mature automotive and construction sectors in countries such as the US and Canada create a substantial requirement for high-quality acrylic surface coatings. Additionally, stringent environmental regulations in North America have spurred the development of eco-friendly and low-VOC acrylic coatings. Furthermore, the growing aerospace sector requires specialized coating for aircraft and components, further bolstering the market in the region. Also, the region is at the forefront of technological advancements in the coatings sector. This includes the development of new formulations, application techniques, and curing processes that improve the performance and sustainability of acrylic coatings.

Europe's acrylic surface coating market analysis states trends are responsible for the progress of the market in the region. The region's mature economies, stringent environmental regulations, and focus on sustainable practices drive requirements for high-quality, eco-friendly acrylic coatings. The automotive sector, particularly in Germany and France, is a major consumer of acrylic coatings. Additionally, the construction sector, especially in Western Europe, is a key driver of market growth. The region's strong emphasis on energy efficiency projects further boosts needs. Also, the aging infrastructure in many European countries requires maintenance and renovation, driving demand for protective coatings. However, factors such as economic fluctuations and geopolitical uncertainties impact the market.

The Middle East and Africa (MEA) acrylic surface coating market analysis states that the region is also witnessing a notable surge. The need for coatings that withstand harsh climatic conditions, such as high temperatures, humidity, and sandstorms, is driving the demand for high-performance acrylic coatings. Moreover, the growing emphasis on architectural design and aesthetics is driving the demand for premium acrylic coatings that offer superior color retention, gloss, and finish. Additionally, the region's strategic geographic location and increasing maritime activities are driving requirements for marine coatings. Acrylic-based marine coatings offer superior corrosion resistance, antifouling properties, and durability, making them ideal for protecting vessels and offshore structures.

Latin America's acrylic surface coating market size is also emerging. Significant investments in infrastructure projects, including roads, bridges, and buildings, are boosting demand for durable and weather-resistant acrylic coatings. Moreover, increasing consumer awareness of the benefits of high-quality coatings, such as durability, aesthetics, and energy efficiency, is driving demand for premium coatings. Additionally, the increasing focus on renewable energy sources, such as solar and wind power, requires specialized coatings to protect components from harsh weather conditions. However, fluctuating exchange rates impact the cost of raw materials and finished products. Income disparities limit the market for coatings in certain countries.

Top Key Players and Market Share Insights:

The Acrylic Surface Coating market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Acrylic Surface Coating market. Key players in the Acrylic Surface Coating industry include-

- AkzoNobel N.V. (Netherlands)

- PPG Industries, Inc. (U.S.)

- Asian Paints (India)

- Dunn-Edwards Corporation (U.S.)

- Everest Systems Co. (U.S.)

- Sherwin-Williams Company (U.S.)

- Axalta Coating System (U.S.)

- Sika AG (Switzerland)

- Nippon Paint (Japan)

- Jotun A/S (Norway)

Recent Industry Developments :

Product Launch:

- In August 2021, Alexseal launched Acrylic Topcoat X. It is a new generation acrylic topcoat designed specifically for the yachting sector, boasting a high gloss finish, exceptional depth of image, and easy application, while offering excellent resistance to UV rays, salt water, abrasion, and fuel.

- In March 2021, Axalta, a leading global coatings provider, introduced Imron Industrial NISO 3325, a new non-isocyanate acrylic enamel topcoat designed for the North American agriculture, construction, and earthmoving equipment markets. This innovative solution prioritizes both performance and safety by eliminating the need for isocyanates, which pose health risks.

Acrylic Surface Coating Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 26,866.16 Million |

| CAGR (2025-2032) | 5.1% |

| By Technology |

|

| By Substrate |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Acrylic Surface Coating Market by 2032? +

The Acrylic Surface Coating Market is projected to reach USD 26,866.16 million by 2032, growing at a CAGR of 5.1% during the forecast period (2025-2032).

Which technology segment dominates the market? +

The water-based coatings segment accounted for the largest market share in 2024, owing to their eco-friendly nature, reduced VOC emissions, and suitability for a variety of applications.

Which region holds the largest market share in the Acrylic Surface Coating Market? +

Asia Pacific accounted for the highest market share in 2024, driven by rapid urbanization, infrastructure development, and a booming automotive sector in countries like China, Japan, and India.

Which region is expected to grow the fastest during the forecast period? +

North America is expected to grow at the fastest CAGR of 5.6%, supported by stringent environmental regulations, a mature construction and automotive sector, and advancements in coating technologies.