- Summary

- Table Of Content

- Methodology

Acrylic Rubber Market Size:

Acrylic rubber market size is estimated to reach over USD 2,310.18 Million by 2032 from a value of USD 1,449.08 Million in 2024, growing at a CAGR of 6.1% from 2025 to 2032.

Acrylic Rubber Market Scope & Overview:

Acrylic rubber also known as alkyl acrylate copolymer (ACM) is a type of synthetic rubber. It is made primarily from acrylate-based monomers like ethyl acrylate and butyl acrylate. There are various properties of acrylic rubber including chemical resistance, excellent resistance to heat as well as ozone, amongst other properties. It is used in a wide range of applications, including automotive, chemical, electronics, aerospace, and others. In automotive, it is employed in seals, gaskets, O-rings, and others. In electronics, it serves as insulation material and a protective layer. There are various benefits of this rubber including durability, versatility, cost-effectiveness, and others. Recent innovations such as the development of vitrimer cross-linked acrylic rubber are driving the market.

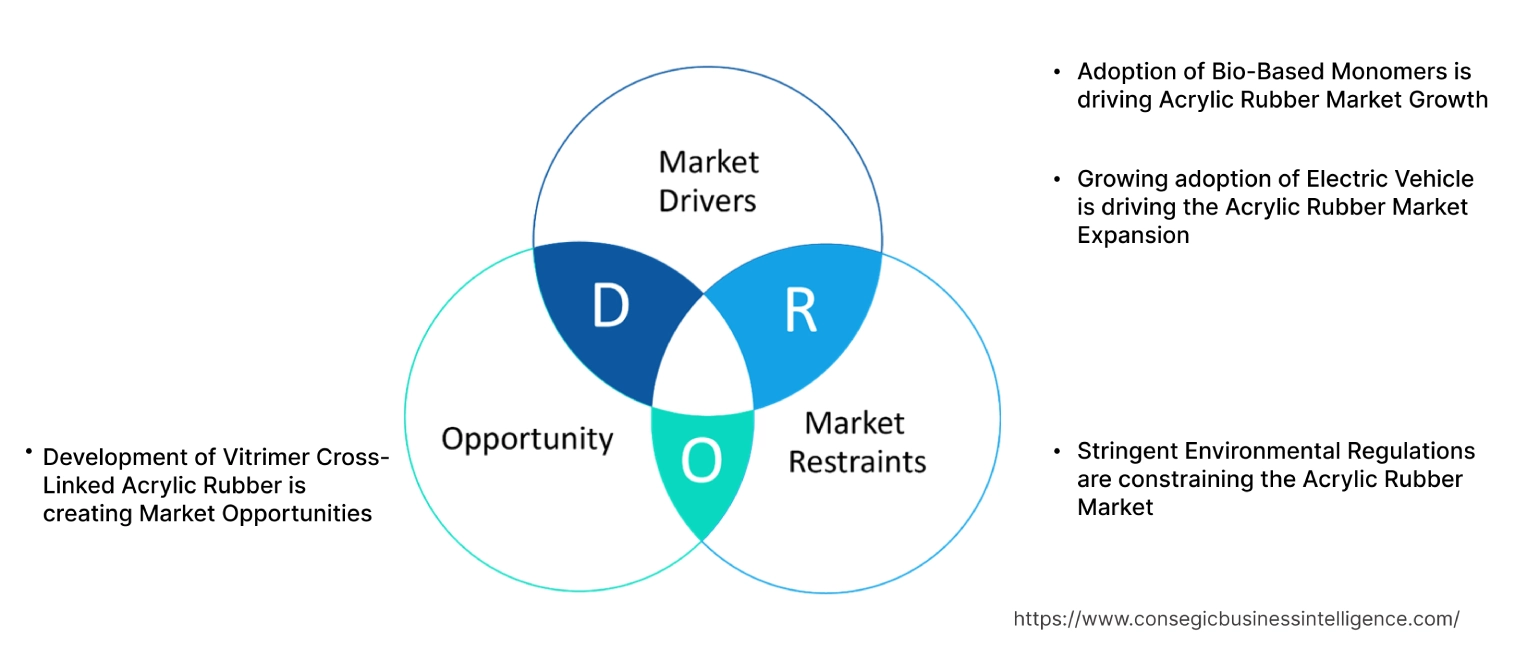

Key Drivers:

Adoption of Bio-Based Monomers is driving Acrylic Rubber Market Growth

Bio-based monomers are derived from bio-based feedstocks, plant seeds, and others. These monomers are primary components used in the production of acrylic rubber. Further, they are biodegradable, non-toxic, and reduce carbon dioxide emissions as compared to traditional fossil-based monomers such as 2-ethylhexyl acrylate (2-EHA) and n-butyl acrylate. The incorporation of bio-based monomers in rubber production is increasing due to stringent environmental regulations and consumer preferences for sustainability solutions.

- In 2023, BASF launched a bio-based 2-octyl acrylate monomer. This bio-based monomer is used in the production of acrylic rubber, reducing the environmental impact. It uses bio-based feedstock and shows excellent weather ability as compared to fossil-based monomers, further incorporating sustainability in the market.

Thus, the integration of bio-based monomers such as 2-Octyl acrylate is driving the acrylic rubber market demand through sustainability and eco-friendly practices.

Growing adoption of Electric Vehicle is driving the Acrylic Rubber Market Expansion

The acrylic rubber plays an important role in ensuring the longevity and efficiency of Electric Vehicle (EV) components, such as insulation for electrical connectors, batteries, and seals among others. The demand for this rubber is rising as EV incorporates complex systems that require high-performance components. The durability and heat resistance of this rubber is essential in EVs for battery packs, inverters, and electric motors.

- In 2023, according to Invest India report, EV sales in India have surged, with over 100,000 units sold for five consecutive months from October 2022 to February 2023. It is driving the market, supported by the increasing use of acrylic rubber in EV components for thermal stability and chemical resistance.

Thus, the growing adoption of the electric vehicle sector is accelerating the acrylic rubber market demand, supported by high-performance components and better thermal protection.

Key Restraints :

Stringent Environmental Regulations are constraining the Acrylic Rubber Market

Environmental regulations significantly restrain the market, as they demand stringent compliance during the manufacturing, usage, and disposal of properties. Regulatory frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and the Environmental Protection Agency (EPA) in the United States and others are imposing regulations on acrylic rubber manufacturers. It imposes regulations to limit emissions, manage chemical waste, and ensure product safety standards. These measures increase operational costs for the manufacturers. Additionally, the acrylic rubber production process relies on petrochemical derivatives, which cause carbon emissions. With the growing focus on sustainability, manufacturers are required to adopt eco-friendly practices, invest in cleaner technologies, and explore renewable sources. This results in high investment costs and delays in the production process.

Thus, environmental regulations are restraining the acrylic rubber market growth, due to regulatory standards and high cost.

Future Opportunities :

Development of Vitrimer Cross-Linked Acrylic Rubber is creating Market Opportunities

The cross-linked acrylic rubber has a cross-linked structure in which the polymer chains are firmly connected, due to which results in less recyclability. The incorporation of vitrimer introduces a combinable cross-linked structure. It shows modifiable and recyclable properties in the rubber, further enhancing the market.

- In 2024, Shinshu University and Nagoya Institute of Technology developed a vitrimer cross-linked acrylic rubber. It incorporates a fast bond recombination reaction at the cross-linking point which results in a recombinable cross-linked structure. This cross-linked rubber is possibly molded with a hot iron and even if it is cut with scissors, it will be reattached and repaired with a household iron showing modifiable and recyclable properties respectively.

Thus, the development of this vitrimer cross-linked acrylic rubber is introducing modifiable and recyclable properties, further creating acrylic rubber market opportunities.

Acrylic Rubber Market Segmental Analysis :

By Source:

By source, the market is divided into ethyl acrylate, butyl acrylate, methoxyethyl acrylate, and others.

Trends in Source:

- According to acrylic rubber market trends, ethyl acrylate is used primarily in production due to its thermal stability and flexibility.

- The use of butyl acrylate in acrylic rubber production is rising due to its chemical resistance and low-temperature performances as per the latest trends.

The ethyl acrylate accounted for the largest market share in the year 2024.

- The ethyl acrylate is a primary monomer used in the production of acrylic rubber contributing significantly to the elastomer’s properties such as heat, oil resistance, and others.

- Its inclusion in the rubber formulations enhances thermal resistance, chemical stability, and flexibility, which are critical for applications in harsh environments.

- Acrylic rubber made with ethyl acrylate exhibits excellent heat resistance, making it ideal for use in high temperatures.

- To cater to the rising demand for ethyl acrylate, companies are incorporating renewable energy sources such as bioethanol in the production of ethyl acrylate.

- For instance, in 2024, Arkema launched ethyl acrylate made entirely from bioethanol. It is a primary component in the production of acrylic rubber. This ethyl acrylate based on bioethanol offers a biocarbon content (BCC) of 40% and a product carbon footprint (PCF) reduction of up to 30%. This will further enhance the market by incorporating sustainability in the production of rubber.

- Thus, ethyl acrylate is widely used in acrylic rubber formulations due to its thermal stability and flexibility.

The butyl acrylate is expected to grow at the fastest CAGR over the forecast period.

- The use of butyl acrylate in acrylic rubber production is rising, primarily enhancing its flexibility and low-temperature performances.

- The inclusion of butyl acrylate in the rubber formulations also enhances its chemical resistance, further advancing its use.

- It further improves oil and fuel resistance, making the rubber well-suited for automotive seals, gaskets, and hoses.

- Use of butyl acrylate typically results in better elongation and compression set resistance in the rubber.

- Furthermore, butyl acrylate improves weathering resistance and ozone resistance, essential for outdoor applications exposed to ultraviolet (UV) radiation.

- Hence, the use of butyl acrylate in acrylic rubber formulations is growing, driven by better chemical resistance and low-temperature performance as per current trends.

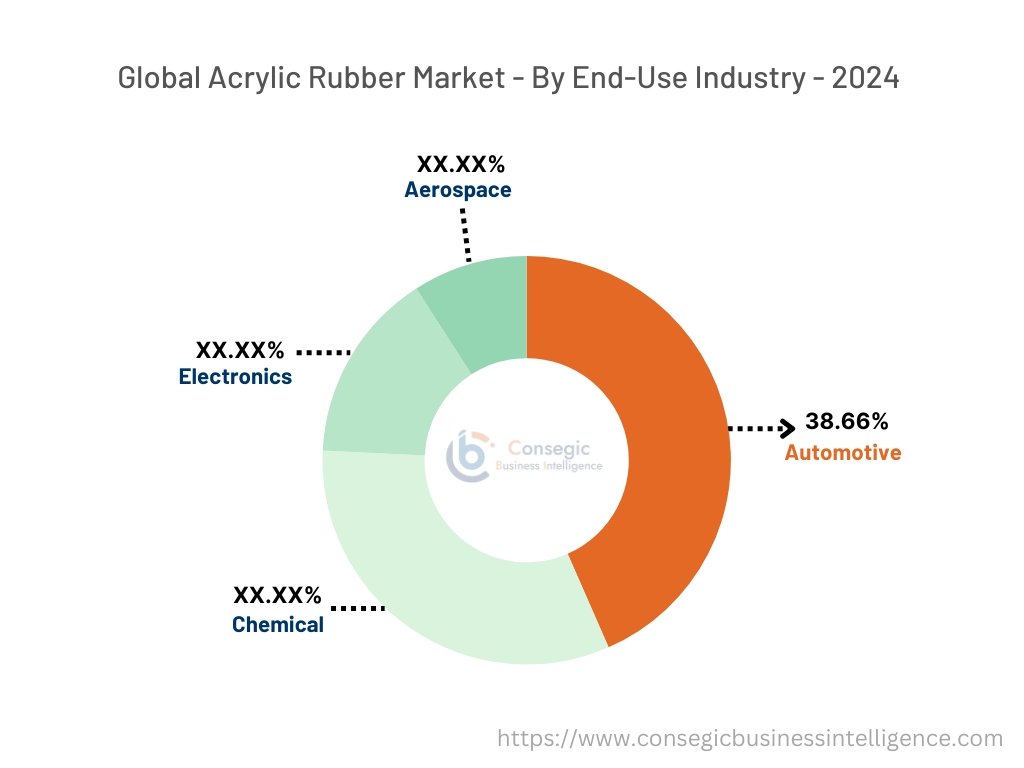

By End-Use Industry:

By end-use industry, the market is divided into automotive, chemical, electronics, aerospace, and others.

Trends in End-Use Industry

- According to acrylic rubber market trends, the use of acrylic rubber in the automotive is rising, due to its flexibility and heat resistance.

- In electronics, acrylic rubber is used for insulating wires and cables for thermal protection as per the latest trends.

Automotive accounted for the largest market share of 38.66% in the year 2024.

- The acrylic rubber is extensively used in the automotive industry due to its heat and oil resistance.

- Its resistance to ozone and ultraviolet radiation further enhances its durability, making it suitable for outdoor automotive parts such as hoses and weather seals.

- Additionally, it is widely applied in automotive components such as engine seals, gaskets, O-rings, and others, which require exposure to high temperatures. The surge in automotive components is further driving the market, supported by the rising need for thermal protection of auto components.

- For instance, in 2023, according to an Invest India report, the automotive components industry shows a growth rate of 32.8% compared to the year 2021. It is driving the market due to the need for acrylic rubber in applications in various automotive parts such as engine seals, gaskets, O-rings, and others.

- Thus, acrylic rubber is widely used in automotive due to its flexibility and heat resistance.

The electronics segment is expected to grow at the fastest CAGR over the forecast period.

- The acrylic rubber is gaining traction in electronics due to its exceptional properties, including high resistance to heat, oil, and chemicals.

- It is widely used for insulating wires and cables, where its thermal stability ensures reliable performance under extreme conditions.

- Its flexibility and durability make it the preferred material for the seals and gaskets in electronic devices, ensuring protection against environmental factors like moisture and dust.

- In advanced electronics, this rubber is used in the encapsulation of sensitive components such as electric circuits and sensors, safeguarding them against mechanical and thermal stress.

- Thus, the use of acrylic rubber is rising in the electronics sector due to its chemical resistance and durability as per current trends.

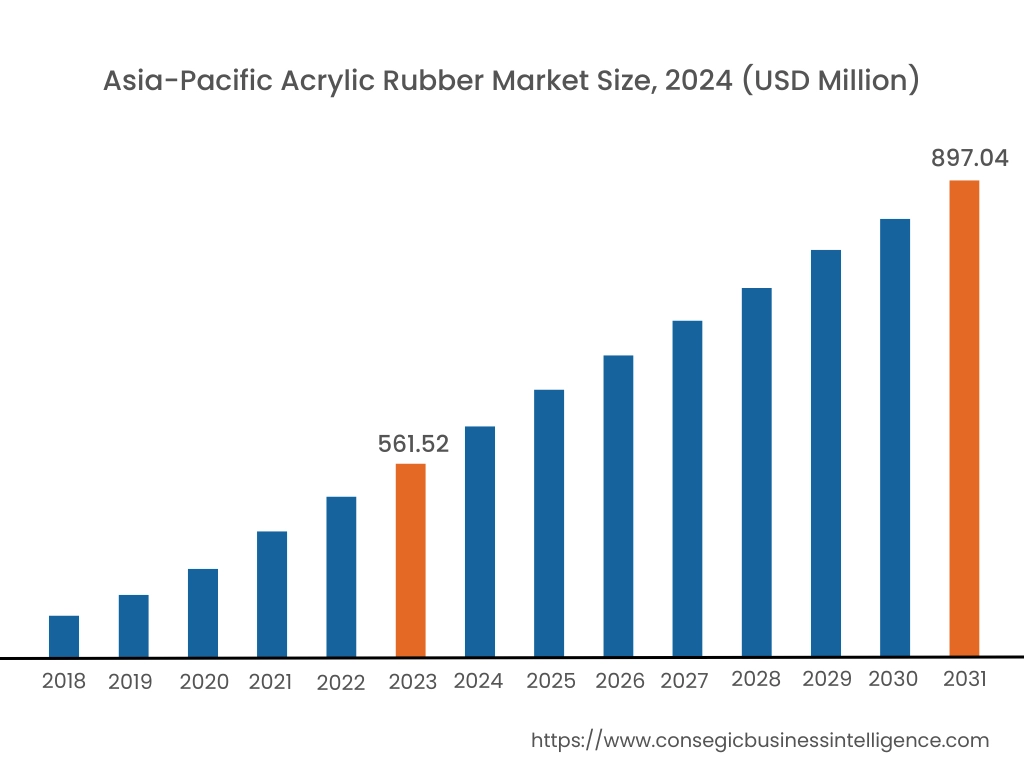

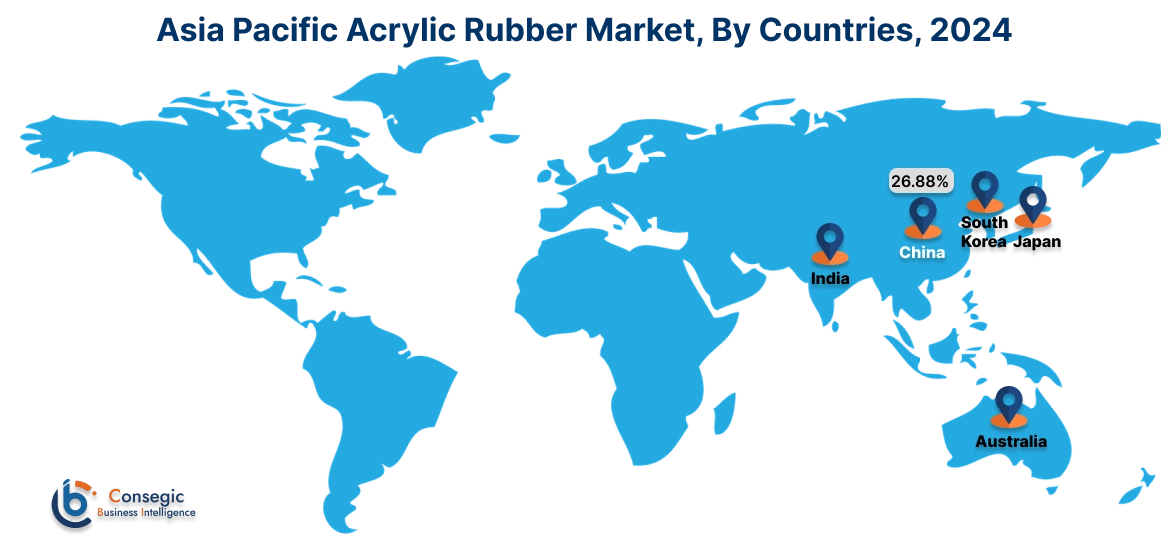

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest market share at 38.75% and was valued at USD 561.52 Million and is expected to reach USD 897.04 Million in 2032. In Asia Pacific, China accounted for the highest market share of 26.88% during the base year of 2024. As per market analysis, the acrylic rubber market share of the Asia-Pacific region is driven by rapid urbanization and industrial developments. The region is a global manufacturing hub, with industries such as electronics, textiles, and machinery heavily relying on this rubber for oil resistance, thermal stability, and more. Countries like China, India, and Japan are major automotive markets, driving the adoption of acrylic rubber in engine seals, gaskets, and O-rings. Further, in India, the production of passenger vehicles, two-wheelers, and others is rising in the automotive sector, driving the market.

- In 2023, according to the Society of Indian Automobile Manufacturers, in India, production of passenger vehicles is 4.5 million units in the year 2023 and it is 25% more than the passenger vehicle production in the year 2022. The acrylic rubber is used in gaskets, seals, and others in passenger vehicles for thermal stability, oil resistance, and more. This surge in the production of passenger vehicles is driving the market.

Thus, the Asia-Pacific region is leading in the market due to well-established automotive infrastructure and wider consumption as per the analysis.

North America is expected to witness the fastest CAGR over the forecast period of 6.5% during 2024-2031. According to market analysis, North America’s acrylic rubber market share is experiencing rapid proliferation in the market, driven by the well-established automotive and electronics sector. The region benefits from a strong automotive sector, which remains a significant consumer of acrylic rubber used in gaskets, bearings, and others. The growing emphasis on electric vehicles in the region is further accelerating the market. The region is also experiencing rapid construction and industrial developments, which is further driving the need for this rubber to ensure the encapsulation of sensitive components such as electric circuits and sensors. Thus, North America is experiencing market growth, driven by technological innovation and the presence of major manufacturers.

According to acrylic rubber market analysis, the European region is growing significantly in the market due to well-established automotive and manufacturing sectors. The European countries are leading in the manufacturing of cars and other vehicles such as trucks, containers, and others, further fueling the market growth. Countries like France, the United Kingdom, and Russia are key contributors due to the major production of advanced rubber formulations such as high-stress and bio-based acrylic rubber. The properties of high thermal stability and higher chemical resistance are the major factors accelerating the growth of the market in the region. Moreover, European manufacturers are investing heavily in research and development of advanced rubber formulations, further driving the acrylic rubber market expansion.

According to acrylic rubber market analysis, the market is expanding in the Middle East and Africa region driven by rapid construction and the growing automotive sector. In countries like Dubai, UAE, and South Africa the market is propelling due to the rapid proliferation of industrial projects and the expanding manufacturing sector. It is fueling the adoption of acrylic rubber in engine seals, gaskets, O-rings, and others. Oil and gas remain significant contributors in this region, as this rubber is critical for heat and chemical resistance. Also, the government in this region is implementing stringent environmental regulations driving the transition towards sustainable and eco-friendly processes for this rubber production. The region is expected to grow significantly in the market, supported by industrial developments and government support.

According to market analysis, Latin America is witnessing moderate growth in the market, driven by expanding industrial activities, rising vehicle ownership, and infrastructure development. Key countries like Brazil, Mexico, and Argentina lead the market due to their strong automotive and industrial sectors. The growing automotive market is a significant contributor, with increasing demand for acrylic rubber in engine seals, gearings, and others. Environmental regulations are encouraging the adoption of bio-based acrylic rubber in the region, driving acrylic rubber market opportunities. However, challenges such as supply chain complexities, rising raw material costs, and regulatory barriers impact the growth of the market in the region.

Top Key Players and Market Share Insights:

The acrylic rubber industry is highly competitive with major players providing precise measurements between objects to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global acrylic rubber market. Key players in the acrylic rubber industry include-

- ZEON CORPORATION. (Japan)

- DuPont de Nemours Inc (United States)

- Hanna Rubber Company (United States)

- Kivi Markings (India)

- CSL Silicones Inc. (Canada)

- Hi-Tech Polymers (India)

- RubberMill, Inc. (United States)

- Tiger Rubber Company (India)

- ZORGE (Netherlands)

- GBSA, Inc. (United States)

Recent Industry Developments :

Partnerships and Collaborations:

- In 2024, Zeon partnered with Visolis to advance bio-isoprene monomer and sustainable aviation fuel(SAF) production. This bio-based monomer will be used in the production of silicone rubber, acrylic rubber, and others. It is driving the market, by reducing dependency on petrochemical monomers and incorporating sustainability.

- In 2023, Mitsubishi Chemical partnered with Honda to develop colored acrylic resin for car bodies. This acrylic resin is known as PMMA (polymethyl methacrylate acrylic) and it is composed of resin and acrylic rubber to improve the impact resistance required for automobile bodies.

Acrylic Rubber Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2,310.18 Million |

| CAGR (2025-2032) | 6.1% |

| By Source |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Acrylic rubber market? +

Acrylic rubber market size is estimated to reach over USD 2,310.18 Million by 2032 from a value of USD 1,449.08 Million in 2024, growing at a CAGR of 6.1% from 2025 to 2032.

What specific segmentation details are covered in the Acrylic rubber market report? +

The Acrylic rubber market report includes specific segmentation details for the source and end-use industry.

Which is the fastest-growing region in Acrylic rubber market? +

North America is the fastest-growing region in the Acrylic rubber market.

Who are the major players in the Acrylic rubber market? +

The key participants in the Acrylic rubber market are ZEON CORPORATION. (Japan), DuPont de Nemours Inc. (United States), Hi-Tech Polymers (India), RubberMill, Inc. (United States), Tiger Rubber Company (India), ZORGE (Netherlands), GBSA, Inc. (United States), Hanna Rubber Company (United States), Kivi Markings (India), CSL Silicones Inc. (Canada).