- Summary

- Table Of Content

- Methodology

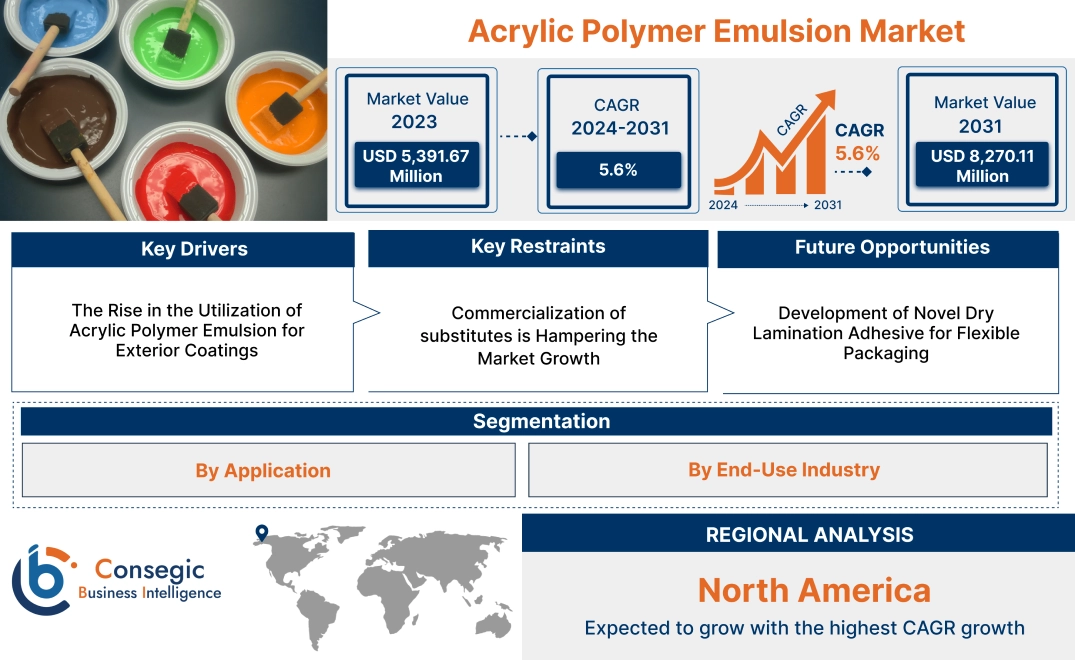

Acrylic Polymer Emulsion Market Size:

Acrylic Polymer Emulsion Market size is growing with a CAGR of 5.6% during the forecast period (2024-2031), and the market is projected to be valued at USD 8,270.11 Million by 2031 from USD 5,391.67 Million in 2023.

Acrylic Polymer Emulsion Market Scope & Overview:

Acrylic polymer emulsions are water-based solutions that use acrylic polymers as the primary binding agent. These polymers are dispersed in water, forming a stable emulsion. When applied to the surface and the water evaporates, the acrylic polymers form a durable, water-resistant film. This film is known for its excellent adhesion, flexibility, and weather resistance. They are categorized by application and end-use industry. In terms of application, they are widely used in paints & coatings, and adhesives and sealants. The construction sector is a major end-user, utilizing acrylic emulsions in paints, coatings, and construction. Automotive, packaging, and textile industries also benefit from the properties of these emulsions.

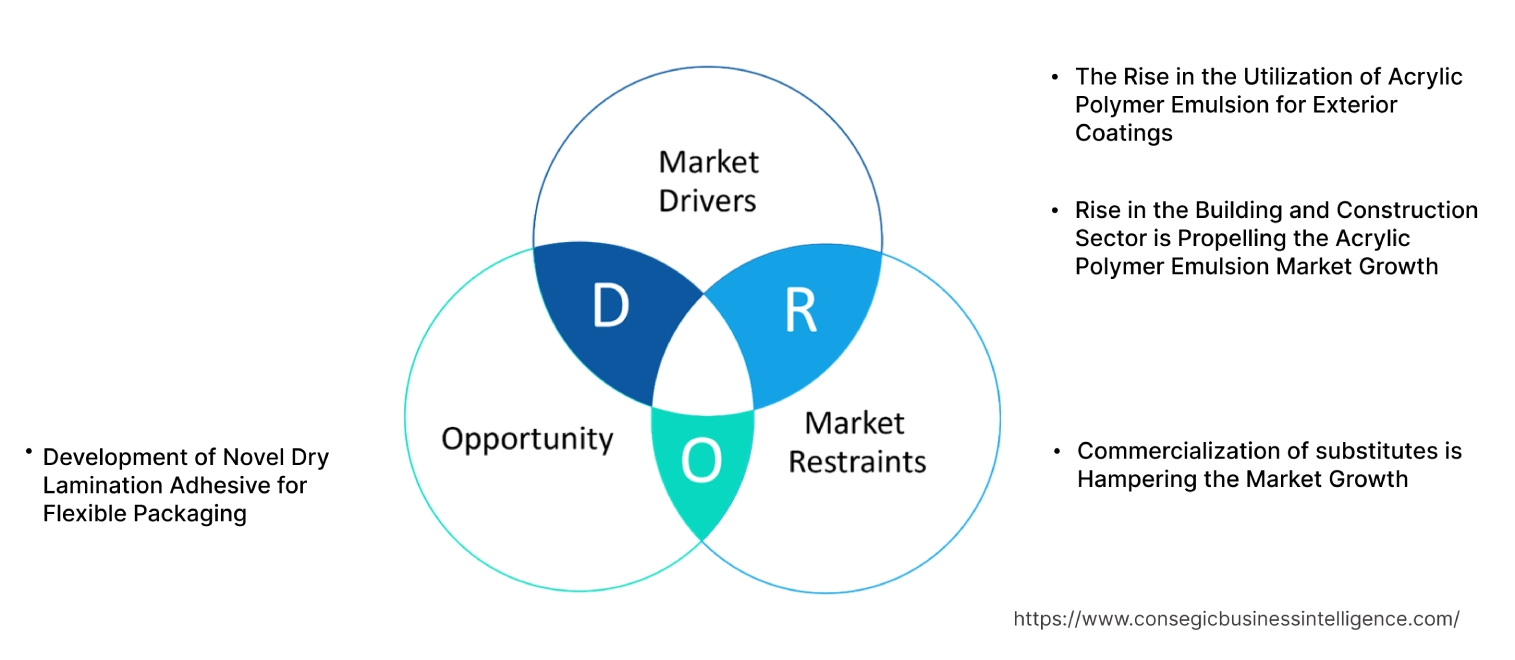

Acrylic Polymer Emulsion Market Dynamics - (DRO) :

Key Drivers:

The Rise in the Utilization of Acrylic Polymer Emulsion for Exterior Coatings

The rising utilization of acrylic polymer emulsions in exterior coatings is driven by their superior performance properties. Acrylic emulsions offer excellent resistance to weathering, UV radiation, and moisture, ensuring long-lasting durability. They also provide flexibility, adhesion, and resistance to cracking and peeling, making them ideal for various exterior applications. Additionally, these emulsions' low VOC content and eco-friendly nature align with growing environmental concerns. Manufacturers are introducing innovative solutions that offer low VOC content and are beneficial for exterior coating.

- For instance, in January 2023, Engineered Polymer Solutions (EPS) introduced EPS 2585, a high-solids waterborne acrylic emulsion designed for direct-to-metal (DTM) applications. This innovative polymer offers excellent performance characteristics, including hardness, flexibility, and corrosion resistance, while meeting stringent low-VOC requirements. Its versatility allows for use in various exterior applications, ensuring long-lasting durability and aesthetic appeal.

Thus, the combination of these factors, coupled with the introduction of innovative low-VOC solutions, is driving the increasing adoption of these emulsions for exterior coating applications.

Rise in the Building and Construction Sector is Propelling the Acrylic Polymer Emulsion Market Growth

The growing building and construction sector is a significant driver of the acrylic polymer emulsion market expansion. The increasing requirement for robust, durable, and aesthetically pleasing buildings and infrastructure projects necessitates the use of high-performance coatings. Acrylic emulsions offer superior properties like excellent adhesion, weather resistance, and durability, making them ideal for diverse applications such as interior and exterior wall paints, primers, and decorative coatings. By enhancing the properties of construction, these solutions contribute to the development of more resilient and long-lasting non-residential structures. These factors are influencing the rise in the construction sector.

- For instance, according to the article published by Eurostat, the annual average construction production in the euro area and EU saw a marginal increase of 0.2% and 0.1%, respectively, in 2023. This surge in construction activity, encompassing infrastructure development, residential and commercial projects, and industrial facilities, is fueling the requirement for acrylic emulsion for construction coating and other applications.

Thus, as the construction sector expands, the requirement for these emulsions is fueled by factors like urbanization, infrastructure development, and rising disposable incomes.

Key Restraints :

Commercialization of substitutes is Hampering the Market Growth

The commercialization of substitute materials is a significant factor hindering the share of the acrylic emulsion market. While acrylic emulsions offer several advantages, such as excellent performance, durability, and environmental friendliness, they face competition from alternative materials such as polyurethane dispersions vinyl acetate-ethylene emulsions, and others.

These substitute materials offer lower costs, improved performance in specific applications, or easier processing. For example, polyurethane dispersions provide superior flexibility and adhesion, while vinyl acetate-ethylene emulsions offer good water resistance and film-forming properties. Overall, as these alternative materials become more widely available and cost-effective, they significantly hinder the acrylic polymer emulsion market growth.

Future Opportunities :

Development of Novel Dry Lamination Adhesive for Flexible Packaging

The development of novel dry lamination adhesives for flexible packaging presents a significant acrylic polymer emulsion market opportunity. Acrylic polymer emulsions are a key component in the formulation of many adhesive products. Their unique properties, such as excellent adhesion, flexibility, and water resistance, make them ideal for various adhesive applications.

The adhesives made using this emulsion are mainly based on acrylic polymer technology and offer several advantages over traditional solvent-based adhesives, including lower VOC emissions, improved environmental sustainability, and enhanced performance. As the requirement for sustainable packaging solutions grows, the use of acrylic emulsions in dry lamination adhesives is expected to increase. Manufacturers are introducing novel adhesives mainly for flexible packaging applications.

- For instance, in July 2024, Trinseo introduced LIGOS™ A 9200 an innovative dry lamination adhesive that offers a compelling combination of performance, efficiency, and environmental friendliness. By utilizing a high-solids acrylic waterborne emulsion, LIGOS™ A 9200 enables faster drying times, higher lamination speeds, and reduced energy consumption.

Thus, the increasing requirement for flexible packaging solutions, coupled with the unique properties of these emulsions, is influencing the acrylic polymer emulsion market opportunities in the coming years.

Acrylic Polymer Emulsion Market Segmental Analysis :

By Application:

Based on applications, the market is categorized into paints & coatings, adhesives & sealants.

Trends in the Application:

- The trend for sustainable adhesives is driving the segment.

- The demand for advanced coating solutions is influencing the growth of the segment.

The paints & coatings segment accounted for the largest market share in 2023.

- Acrylic polymer emulsions have enhanced the paint and coatings sector due to their exceptional properties and versatility.

- They offer excellent bonding properties to various surfaces, including wood, metal, and masonry, ensuring long-lasting durability.

- These emulsions exhibit superior weather resistance, protecting surfaces from UV radiation, moisture, and temperature fluctuations. Additionally, they provide excellent color retention, preventing fading and chalking over time. These emulsions offer a wide range of finishes, from high gloss to matte, catering to diverse aesthetic preferences.

- Their water-based nature makes them environmentally friendly and easy to apply, reducing VOC emissions and simplifying cleanup.

- Various manufacturers offer novel solutions for paints and coating applications.

- For instance, MCTRON Technologies introduced Maxxacryl AC-3025, which is a high-performance acrylic polymer emulsion. It offers exceptional adhesion, strong pigment binding, and superior durability. The polymer dries clear, resists water, and provides excellent gloss. It's versatile and compatible with a wide range of additives like fillers, pigments, and dyes.

- Overall, with their combination of performance, durability, and ease of use, acrylic emulsions are being utilized for both interior and exterior paints, providing a protective and aesthetically pleasing finish.

The adhesives & sealants segment is expected to grow at the fastest CAGR over the forecast period.

- Acrylic polymer emulsions are widely used in the formulation of adhesives and sealants due to their versatility and performance.

- They offer excellent adhesion to a variety of substrates, including paper, wood, metal, and plastic. These emulsions provide strong initial tack, good final bond strength, and excellent water resistance.

- They also exhibit flexibility, allowing them to accommodate substrate movement and prevent cracking or peeling. Additionally, these emulsions offer good aging resistance, maintaining their adhesive properties over time.

- Overall, based on the acrylic polymer emulsion market analysis, these properties make acrylic emulsions ideal for a wide range of adhesive and sealant applications, including pressure-sensitive adhesives, construction adhesives, and sealants for various substrates, thus driving the acrylic polymer emulsion market expansion.

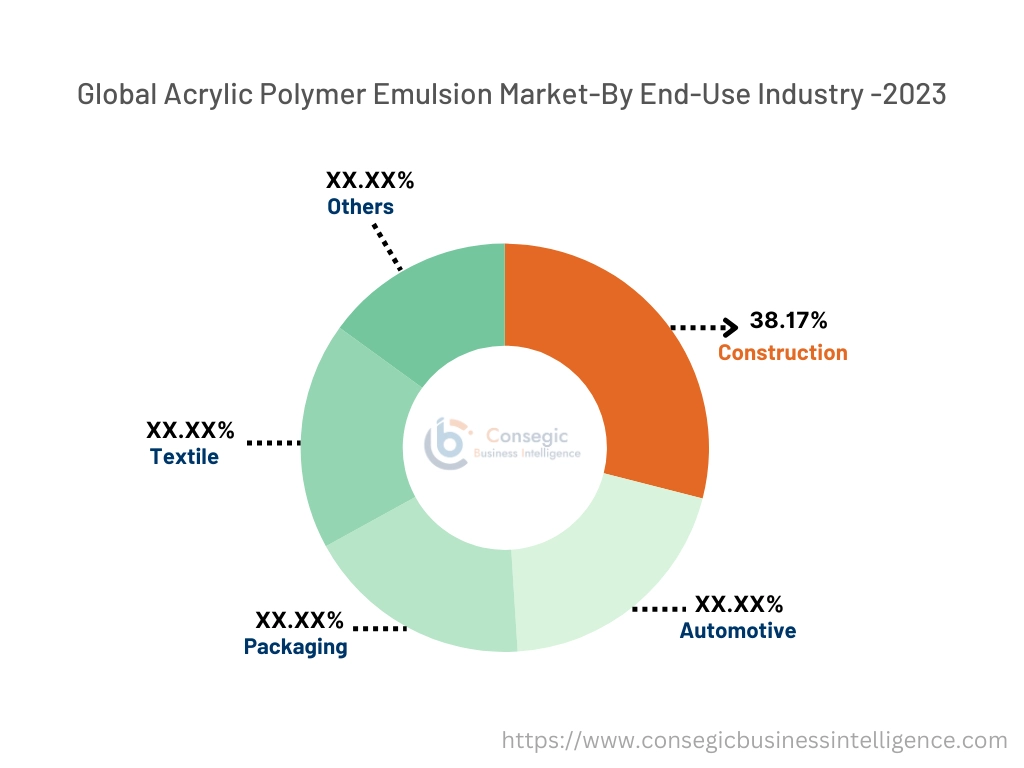

By End-Use Industry:

Based on the end-use industry, the market is categorized into construction, automotive, packaging, textile, and others.

Trends in the end-use industry:

- The utilization of acrylic emulsions for automotive coating is influencing segment growth.

- The trend for high-performance adhesives in the construction sector is influencing the segment.

The construction segment accounted for the largest acrylic polymer emulsion market share of 38.17% in the year 2023.

- Acrylic polymer emulsions play a crucial role in the construction sector, offering a wide range of benefits.

- In construction, they provide excellent adhesion, durability, and weather resistance, protecting surfaces from harsh environmental conditions. They are used in both interior and exterior paints, ensuring long-lasting finishes.

- Additionally, acrylic emulsions are utilized in adhesives and sealants, providing strong bonds and water resistance.

- They are essential in construction projects, from sealing joints and cracks to bonding various materials. These emulsions contribute to the overall durability and longevity of buildings and infrastructure, making them indispensable in the construction sector.

- Moreover, the rise in the trends for the construction of new residential buildings leads to the utilization of these emulsions in various applications.

- For instance, according to a joint announcement by the S. Census Bureau and the U.S. Department of Housing and Urban Development, approximately 1.31 million new housing units were started and 1.61 million were completed in 2024. This influences the use of acrylic emulsion as these emulsions offer several advantages in construction, such as durability, weather resistance, and ease of application among others

- Thus, the aforementioned factors are driving the demand for the acrylic polymer emulsion market trend.

The packaging segment is expected to grow at the fastest CAGR over the forecast period.

- Acrylic polymer emulsions play a crucial role in the packaging sector, offering a range of benefits.

- They are used in various applications, including coatings, adhesives, and laminates.

- In coatings, these emulsions enhance the surface properties of packaging materials, improving their printability, water resistance, and barrier properties.

- As adhesives, they provide strong bonds for paper and board, ensuring the integrity of packaging.

- In laminates, these emulsions act as a binding agent, combining different materials like paper, plastic, and metal to create durable and versatile packaging solutions.

- These emulsions offer excellent adhesion, flexibility, and resistance to moisture and chemicals, making them ideal for protecting products and extending their shelf life.

- Overall, by utilizing these emulsions, the packaging sector is able to produce sustainable, high-performance, and visually appealing packaging solutions, thus driving the acrylic polymer emulsion market demand and trend in coming years.

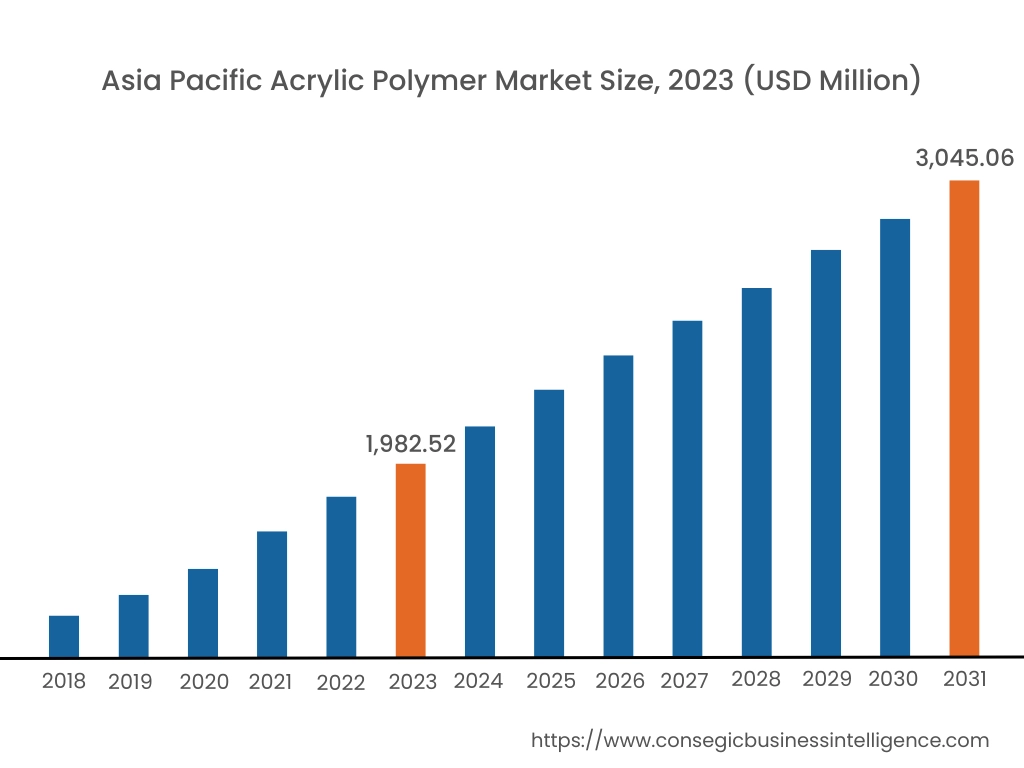

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

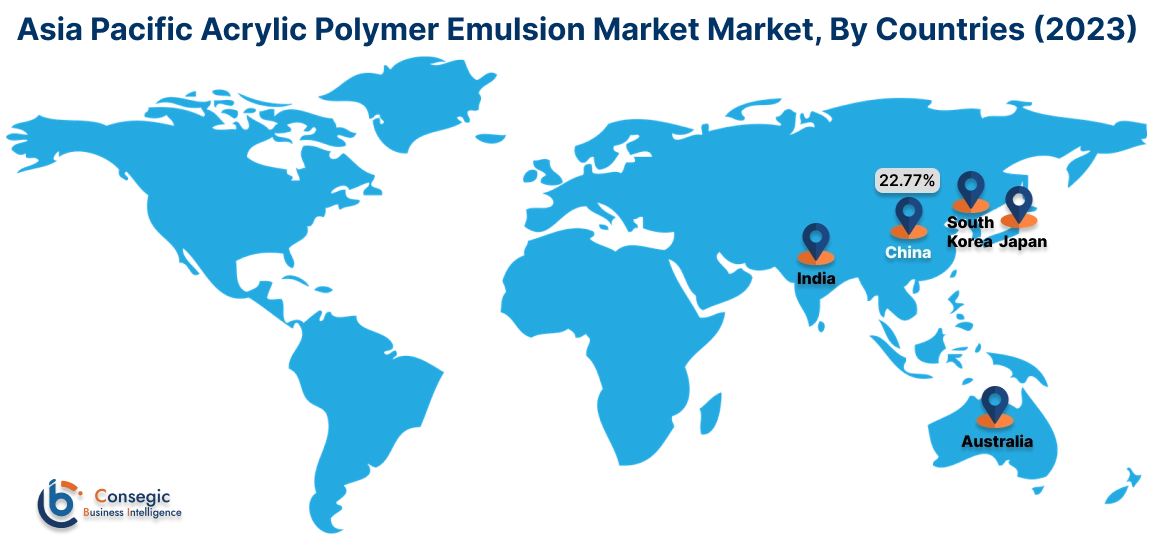

In 2023, Asia Pacific accounted for the highest acrylic polymer emulsion market share at 36.77% and was valued at USD 1,982.52 Million and is expected to reach USD 3,045.06 Million in 2031. In Asia Pacific, China accounted for the highest market share of 22.77% during the base year of 2023. The Asia-Pacific region has witnessed significant growth in the construction and automotive industries, driving the requirement for high-performance coatings and adhesives. Acrylic emulsions have emerged as a key solution, offering a balance of performance, cost-effectiveness, and environmental friendliness. These emulsions are widely used in architectural coatings, providing excellent adhesion, durability, and weather resistance, particularly in regions with diverse climatic conditions. In the automotive sector, these emulsions are used in automotive coatings to enhance the appearance and durability of vehicles. Additionally, as per the analysis, they find applications in adhesives and sealants, contributing to the region's rapid infrastructure development. As the Asia-Pacific region continues to expand, the acrylic polymer emulsion market demand is growing, driven by urbanization, industrialization, and a rising middle class.

The North American market for Acrylic Polymer Emulsions is experiencing the fastest growth with a CAGR of 6.1% over the forecast period. As per the acrylic polymer emulsion market analysis, in North America, acrylic emulsions have become an essential solution for paints and coating applications. Their versatility, durability, and environmental friendliness have led to widespread adoption. These emulsions are extensively used in architectural coatings for both interior and exterior applications, providing excellent adhesion, weather resistance, and color retention. Additionally, they are employed in industrial coatings, offering protection against corrosion and wear. The construction sector benefits from these emulsions in adhesives and sealants, ensuring strong bonds and water resistance. The rise in construction establishments influences the use of acrylic emulsion.

- For instance, in April 2024, Lubrizol, a leading global specialty chemical company, announced a significant USD 20 million investment in its Gastonia, North Carolina plant. This investment is aimed at enhancing the production capacity of innovative acrylic emulsion.

The region's stringent environmental regulations have further driven the adoption of water-based emulsions, reducing the use of solvent-based alternatives. As a result, acrylic polymer emulsions have become an indispensable component of the North American paint and coatings market.

In Europe, acrylic polymer emulsions have gained significant popularity due to their excellent performance and environmental friendliness. They are widely used in architectural coatings, providing durable and aesthetically pleasing finishes for both interior and exterior surfaces. These emulsions offer superior weather resistance, protecting buildings from harsh weather conditions. Additionally, they are employed in industrial coating, safeguarding metal structures and machinery from corrosion. The construction sector benefits from acrylic-based adhesives and sealants, ensuring strong bonds and water resistance. European regulations prioritize sustainability and environmental impact, making water-based acrylic emulsions an ideal choice for various applications. As a result, based on the market analysis, acrylic polymer emulsions have become an integral part of the European paint and coatings sector, contributing to the region's commitment to sustainable building practices and creating significant opportunities for development.

In the Middle East and Africa, acrylic polymer emulsions have gained significant traction due to their exceptional performance and adaptability to diverse climatic conditions. These regions often experience extreme temperatures, high humidity, and exposure to harsh UV radiation. Acrylic emulsions offer excellent resistance to these environmental factors, ensuring the durability and longevity of coatings. They are widely used in architectural coatings to protect buildings from weather and corrosion. Additionally, acrylic emulsions find applications in industrial coatings, protecting machinery and equipment from harsh conditions. In the construction sector, they are used in adhesives and sealants, providing strong bonds and water resistance. As per the market analysis, as the infrastructure and construction sectors continue to grow in these regions, the demand for high-performance sustainable coatings is increasing, making acrylic emulsions a vital component of the paint and coatings sector in the Middle East and Africa.

In Latin America, acrylic polymer emulsions have gained significant traction due to their versatility, durability, and cost-effectiveness. They are widely used in architectural coatings, offering excellent adhesion, weather resistance, and color retention, particularly important in regions with diverse climatic conditions. Additionally, acrylic emulsions are used in industrial coatings to protect surfaces from corrosion and wear. The construction sector benefits from acrylic emulsions in adhesives and sealants, ensuring strong bonds and water resistance. Based on the analysis, as Latin American countries prioritize infrastructure development and housing projects, the demand for high-performance, sustainable building materials, including acrylic polymer emulsions, is on the rise. This is further fueled by increasing consumer awareness of the benefits of quality paints and coatings, driving the growth of the acrylic polymer emulsion market trends in the region.

Acrylic Polymer Emulsion Market Competitive Landscape:

The acrylic polymer emulsion market is highly competitive with major players providing novel products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global acrylic polymer emulsion market. Key players in the acrylic polymer emulsion industry include-

- Dow (United States)

- BASF (Germany)

- Mallard Creek Polymers (United States)

- Nippon Shokubai Co., Ltd. (Japan)

- Kamsons Chemicals Pvt. Ltd (India)

- MCTRON Inc. (United States)

- Celanese Corporation (United States)

- Arkema S.A. (France)

- Avery Dennison Corporation (United States)

- The Lubrizol Corporation (United States)

Recent Industry Developments:

Investments and Fundings:

- In April 2024, Lubrizol, a leading global specialty chemical company, announced a significant USD 20 million investment in its Gastonia, North Carolina plant. This investment is aimed at enhancing the production capacity of innovative acrylic emulsion.

Product Launches:

- In July 2024, Trinseo introduced LIGOS™ A 9200 is a significant advancement in flexible packaging solutions. This innovative dry lamination adhesive offers a compelling combination of performance, efficiency, and environmental friendliness. By utilizing a high-solids acrylic waterborne emulsion, LIGOS™ A 9200 enables faster drying times, higher lamination speeds, and reduced energy consumption.

Acrylic Polymer Emulsion Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 8,270.11 Million |

| CAGR (2024-2031) | 5.6% |

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Acrylic Polymer Emulsion Market? +

In 2023, the Acrylic Polymer Emulsion Market is USD 5,391.67 Million.

Which is the fastest-growing region in the Acrylic Polymer Emulsion Market? +

North America is the fastest-growing region in the Acrylic Polymer Emulsion Market.

What specific segmentation details are covered in the Acrylic Polymer Emulsion Market? +

Application and End-Use Industry segmentation details are covered in the Acrylic Polymer Emulsion Market

Who are the major players in the Acrylic Polymer Emulsion Market? +

Dow (United States), BASF (Germany), MCTRON Inc. (United States), Celanese Corporation (United States), Arkema S.A. (France), Avery Dennison Corporation (United States), The Lubrizol Corporation (United States), Mallard Creek Polymers (United States), Nippon Shokubai Co., Ltd. (Japan), and Kamsons Chemicals Pvt. Ltd (India).