- Summary

- Table Of Content

- Methodology

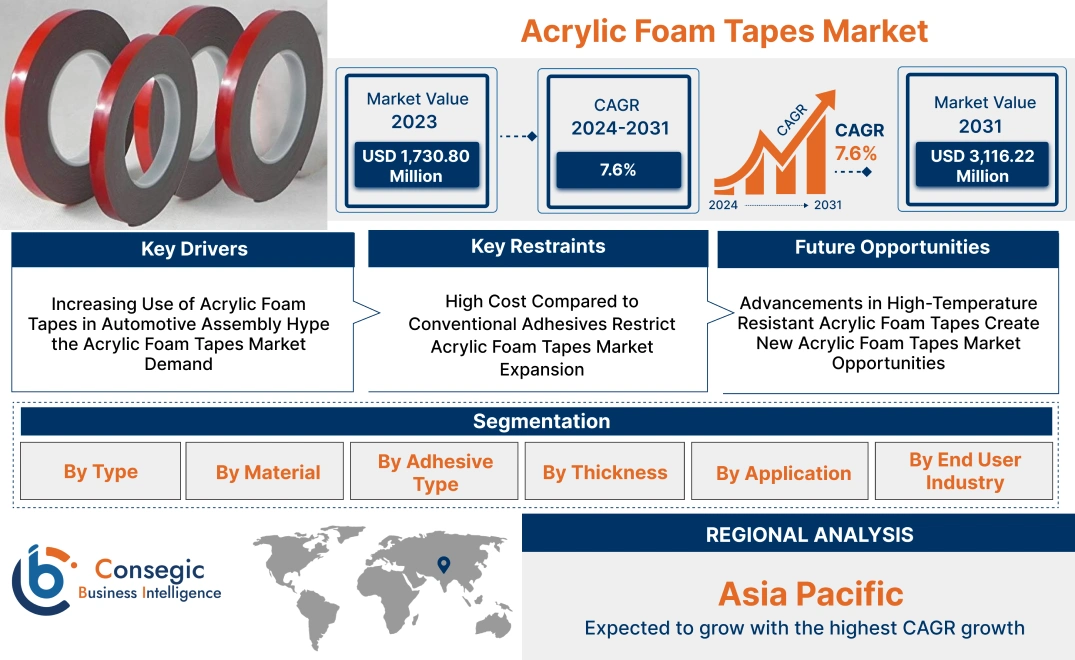

Acrylic Foam Tapes Market Size:

Acrylic Foam Tapes Market Market size is estimated to reach over USD 3,116.22 Million by 2031 from a value of USD 1,730.80 Million in 2023 and is projected to grow by USD 1,831.98 Million in 2024, growing at a CAGR of 7.6% from 2023 to 2031.

Acrylic Foam Tapes Market Scope & Overview:

Acrylic foam tapes are pressure-sensitive adhesives made from viscoelastic acrylic material, offering strong adhesion and excellent durability. These tapes exhibit properties such as high tensile strength, resistance to environmental factors, and the ability to distribute stress uniformly. They are available in various thicknesses and sizes to meet diverse application requirements. Acrylic foam tapes provide benefits such as superior bonding capabilities, reduced need for mechanical fasteners, and enhanced aesthetic appeal. Their ability to maintain adhesion under extreme temperatures and resist chemicals makes them suitable for demanding environments. Additionally, they help reduce noise and vibration, contributing to improved product performance.

Applications of acrylic foam tapes are widespread, including bonding, sealing, mounting, and insulation. They are extensively used in industries such as automotive, construction, electronics, and signage. Automotive manufacturers use these tapes for attaching exterior trims and emblems, while the construction sector employs them for glazing and sealing applications. The electronics industry benefits from their use in assembling devices and components. End-use industries for acrylic foam tapes include automotive, construction, consumer electronics, healthcare, and industrial manufacturing, where strong and reliable adhesion is critical to product quality and performance.

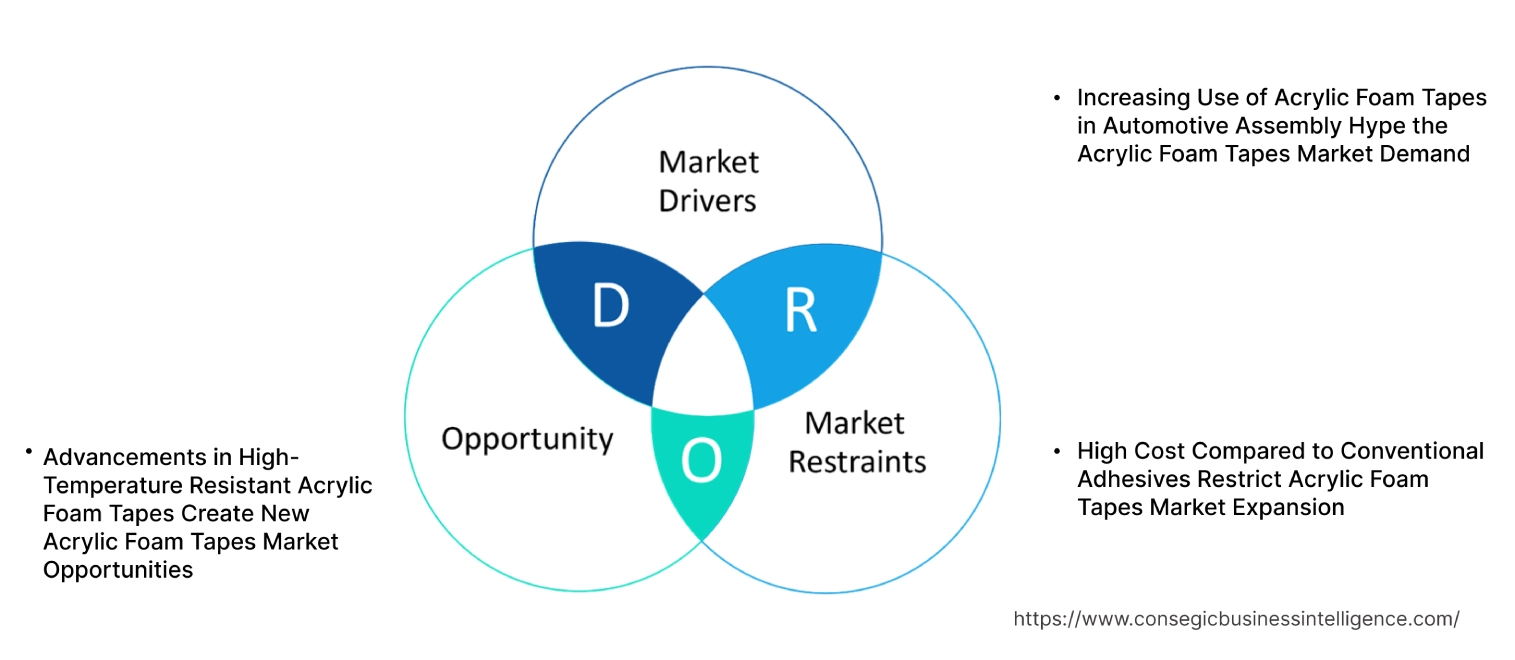

Key Drivers:

Increasing Use of Acrylic Foam Tapes Market in Automotive Assembly Hype the Acrylic Foam Tapes Market Market Demand

Acrylic foam tapes are increasingly being utilized in automotive assembly processes due to their superior bonding and aesthetic advantages. These tapes provide excellent adhesion to various materials such as metals, plastics, and painted surfaces, replacing traditional mechanical fasteners like screws or bolts. By using these tapes, manufacturers can achieve lightweight assemblies, enhance durability, and improve vehicle aesthetics by eliminating visible fastening points. For instance, automotive manufacturers use acrylic foam tapes to attach body side moldings, emblems, and weatherstrips, ensuring a seamless and robust bond. This growing adoption in automotive assembly is significantly boosting the acrylic foam tapes market trend.

Key Restraints :

High Cost Compared to Conventional Adhesives Restrict Acrylic Foam Tapes Market Market Expansion

Acrylic foam tapes are often associated with higher costs compared to conventional adhesives or fasteners, which may restrict their widespread use. The manufacturing process and raw materials involved in producing high-quality acrylic foam tapes contribute to their elevated price. Small-scale industries and cost-sensitive sectors may find it challenging to adopt these tapes, opting instead for cheaper alternatives that meet their basic requirements. For example, traditional adhesives or fasteners are often preferred in low-budget applications, limiting the scope for acrylic foam tapes. This cost barrier hinders the acrylic foam tapes market growth by reducing the adoption rate, particularly in price-sensitive regions and industries.

Future Opportunities :

Advancements in High-Temperature Resistant Acrylic Foam Tapes Market Create New Acrylic Foam Tapes Market Market Opportunities

The development of high-temperature resistant acrylic foam tapes is expected to create significant growth opportunities in the market. Industries such as electronics and aerospace require bonding solutions that can withstand extreme temperatures without compromising performance. Manufacturers are focusing on innovating acrylic foam tapes with enhanced thermal resistance properties to cater to these demanding applications. For instance, such tapes could be used in bonding components within electric vehicles, where heat management is critical. The growing trend for these specialized tapes in high-temperature environments will open new avenues for acrylic foam tapes market expansion, enhancing the application scope of acrylic foam tapes in the future.

Acrylic Foam Tapes Market Segmental Analysis :

By Type:

Based on type, the acrylic foam tapes market is segmented into double-sided, single-sided, and self-stick.

The double-sided tape segment accounted for the largest revenue in acrylic foam tapes market share in 2023.

- Double-sided tapes are preferred for their strong adhesion, versatility, and ability to bond different materials, including metal, glass, and plastic.

- These tapes are extensively used in the automotive and electronics industries for assembling parts and components.

- They offer clean, durable, and seamless bonding solutions, eliminating the need for screws or bolts.

- Their resistance to heat, humidity, and solvents enhances their utility in challenging environments.

- Additionally, double-sided tapes are gaining traction in the construction sector for structural glazing and cladding applications.

- Therefore, according to acrylic foam tapes market analysis, the double-sided tape segment's dominance is attributed to its extensive industrial applications, superior performance, and reliable bonding properties.

The self-stick tape segment is anticipated to register the fastest CAGR during the forecast period.

- Self-stick tapes are widely utilized in packaging, lightweight assemblies, and DIY applications due to their ease of application.

- They reduce installation time and do not require additional tools or adhesives, making them highly convenient.

- Their growing use in residential and commercial applications contributes to the acrylic foam tapes market growth.

- These tapes are particularly popular in temporary bonding and mounting applications.

- Rising trend for simplified and cost-effective solutions further boosts their adoption.

- Thus, according to acrylic foam tapes market analysis, self-stick tapes are witnessing rapid growth due to their user-friendly features, making them ideal for quick and versatile applications across various sectors.

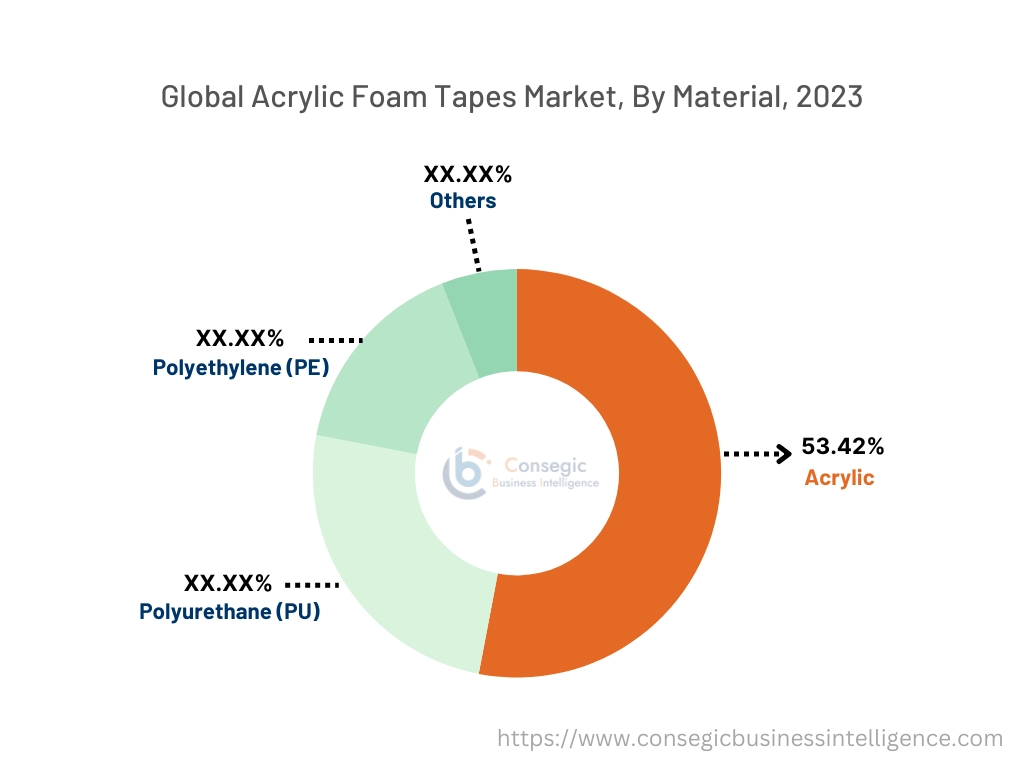

By Material:

Based on material, the market is segmented into polyethylene (PE), polyurethane (PU), acrylic, and others.

The acrylic material segment accounted for the largest revenue share of 53.42% in acrylic foam tapes market share in 2023.

- Acrylic-based tapes are known for their excellent adhesion, resistance to UV rays, and environmental durability.

- They are extensively utilized in the automotive and construction sectors for heavy-duty bonding.

- These tapes withstand temperature extremes, making them suitable for outdoor and industrial applications.

- Their transparency and weatherproof properties enhance their use in aesthetic bonding for glass and signage.

- Acrylic materials are also favored for their longer lifespan and low maintenance requirements.

- Therefore, according to market analysis, acrylic materials dominate the market due to their superior properties, long-term reliability, and suitability for diverse industrial uses.

The polyethylene (PE) segment is anticipated to register the fastest CAGR during the forecast period.

- PE-based tapes are eco-friendly and recyclable, aligning with growing environmental concerns.

- Their lightweight and flexible properties make them suitable for packaging and lightweight assemblies.

- These tapes are cost-effective and provide reliable bonding solutions in non-critical applications.

- The growing emphasis on sustainable materials drives the demand for PE-based tapes.

- Increased adoption in e-commerce packaging and other industries supports their rapid growth.

- Thus, according to market analysis, the PE segment is growing quickly due to its sustainability, affordability, and adaptability in various non-industrial applications.

By Adhesive Type:

Based on adhesive type, the market is segmented into solvent-based, water-based, and hot melt-based.

The solvent-based adhesive segment accounted for the largest revenue share in 2023.

- Solvent-based adhesives offer high bonding strength and temperature resistance, making them ideal for demanding applications.

- They are widely used in the automotive and aerospace industries for structural bonding.

- These tapes excel in harsh conditions, providing durability and reliability.

- Their ability to bond diverse materials such as metals and composites enhances their versatility.

- Solvent-based adhesives maintain adhesion under exposure to moisture, oils, and chemicals.

- Therefore, according to market analysis, the solvent-based adhesive segment leads the market due to its superior performance in high-demand industrial applications.

The water-based adhesive segment is anticipated to register the fastest CAGR during the forecast period.

- Water-based adhesives are environmentally friendly, with low VOC emissions, making them a sustainable option.

- Their application spans packaging, labeling, and lightweight bonding solutions.

- The increasing shift toward eco-friendly solutions in various industries promotes their adoption.

- These adhesives are cost-effective and suitable for non-critical applications.

- Growing regulations on VOCs and environmental compliance fuel the acrylic foam tapes market demand.

- Thus, according to market analysis, water-based adhesives are rapidly gaining traction due to their environmental benefits and suitability for lightweight applications.

By Thickness:

Based on thickness, the market is segmented into less than 1mm, 1mm to 2mm, and more than 2mm.

The 1mm to 2mm thickness segment accounted for the largest revenue share in 2023.

- This thickness range offers a balance of strength and flexibility, making it suitable for industrial applications.

- Tapes in this category are commonly used for bonding, mounting, and insulation purposes.

- Their optimal thickness ensures compatibility with diverse surfaces, including rough and uneven ones.

- They are favored in automotive and construction sectors for durable bonding solutions.

- Resistance to environmental factors like heat and moisture enhances their utility.

- Therefore, according to market analysis, the 1mm to 2mm thickness segment dominates the market due to its versatility and widespread adoption in industrial applications.

The less than 1mm segment is anticipated to register the fastest CAGR during the forecast period.

- Thin tapes are extensively used in precision applications such as electronics assembly and labeling.

- They provide lightweight solutions without compromising adhesion strength.

- These tapes are increasingly adopted in miniaturized devices and compact assemblies.

- Their unobtrusive nature is ideal for applications requiring a clean and seamless finish.

- Growing trend for compact and lightweight designs across industries supports their expansion.

- Thus, according to market analysis, thin tapes are growing rapidly due to their suitability for precision and lightweight applications, especially in electronics and advanced assemblies.

By Application:

Based on application, the market is segmented into bonding, mounting, sealing, insulation, and others.

The bonding segment accounted for the largest revenue share in 2023.

- Acrylic foam tapes are essential for bonding applications, offering superior adhesive strength and durability.

- They are widely used in automotive, construction, and electronics industries for permanent bonding solutions.

- Their ability to eliminate mechanical fasteners improves aesthetics and reduces material costs.

- Bonding applications include assembling panels, trim, and structural components.

- The use of high-performance adhesives in bonding applications ensures long-term reliability.

- Therefore, according to market analysis, the bonding segment dominates the market due to its versatile and durable nature, catering to diverse industrial needs.

The sealing segment is anticipated to register the fastest CAGR during the forecast period.

- Sealing tapes are used for moisture and air resistance in applications like construction and HVAC systems.

- They provide excellent insulation and barrier properties for protective purposes.

- Rising infrastructure development and renovation projects boost their adoption.

- Their efficiency in preventing leaks and ensuring energy conservation increases trend.

- Sealing tapes are preferred for applications requiring high environmental resistance.

- Thus, according to market analysis, the sealing segment is rapidly growing due to its critical role in enhancing insulation and environmental protection across various industries.

By End-Use Industry:

Based on end-user industry, the market is segmented into automotive, building & construction, electronics, aerospace, and others.

The automotive industry accounted for the largest revenue share in 2023.

- Acrylic foam tapes are widely used for bonding exterior panels, trims, and structural components in vehicles.

- They help reduce vehicle weight and enhance fuel efficiency by replacing mechanical fasteners.

- Their resistance to vibration, temperature, and weather ensures long-term durability in automotive applications.

- These tapes also improve vehicle aesthetics by enabling seamless bonding.

- Increasing vehicle production and advancements in lightweight materials contribute to the acrylic foam tapes market trend

- Therefore, according to market analysis, the automotive sector leads the market due to the extensive use of acrylic foam tapes in vehicle assembly and design.

The electronics industry is anticipated to register the fastest CAGR during the forecast period.

- Acrylic foam tapes are used for bonding electronic components and providing insulation in devices.

- They offer thermal stability and adhesive strength required for advanced electronics.

- Growing trend for compact and efficient devices fuels their adoption in the electronics sector.

- They enable precise bonding, reducing the size and weight of electronic assemblies.

- The rising popularity of wearables and smart devices enhances their market prospects.

- Thus, according to market analysis, the electronics sector is expanding rapidly due to technological advancements and increasing demand for lightweight and compact electronic products.

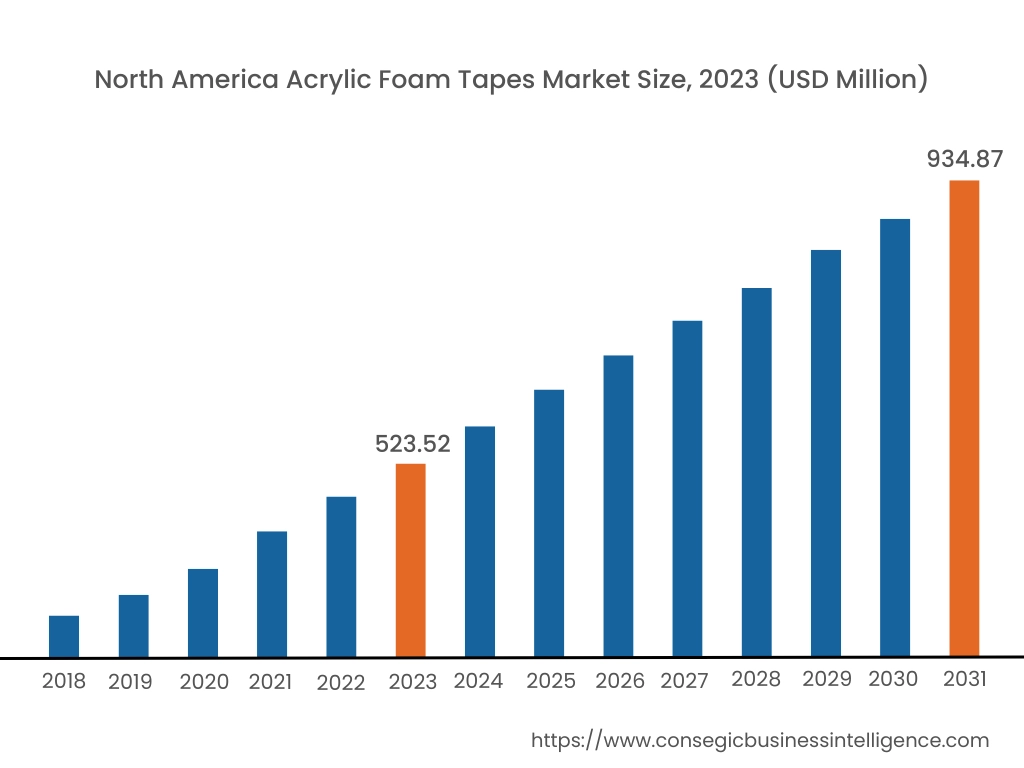

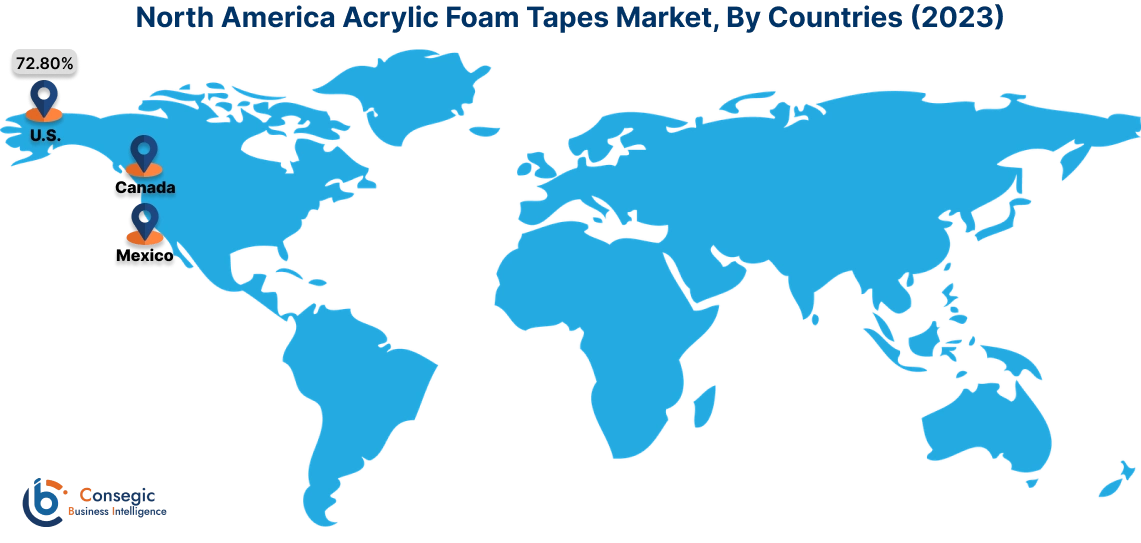

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

In 2023, North was valued at USD 523.52 Million and is expected to reach USD 934.87 Million in 2031. In North America, the U.S. accounted for the highest share of 72.80% during the base year of 2023. North America holds a significant share in the acrylic foam tapes market, primarily led by demand from the automotive, construction, and electronics industries. The United States and Canada have established strong production and consumption bases for acrylic foam tapes, driven by the rising adoption of these tapes in applications such as bonding, insulation, and vibration damping. Stringent regulations on environmental sustainability and increasing consumer preference for efficient adhesive solutions are key factors influencing market performance in the region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 7.9% over the forecast period. The region, particularly China, Japan, and India, benefits from a booming manufacturing sector, including automotive, electronics, and construction, all of which are significant consumers of acrylic foam tapes. The growing emphasis on lightweight materials in automotive manufacturing and the increasing need for energy-efficient buildings further boost the acrylic foam tapes market demand. Competitive pricing and the availability of raw materials in Asia-Pacific support the continued market expansion.

Europe remains a prominent market for acrylic foam tapes, driven by advanced automotive and construction sectors. Germany, France, and the UK are key markets for acrylic foam tapes due to the rising trend of automotive lightweighting, where these tapes are extensively used for bonding and sealing applications. The region’s focus on sustainability and eco-friendly solutions also enhances the demand for acrylic foam tapes, particularly in the packaging and construction sectors, where energy efficiency is a priority.

The acrylic foam tapes market in the Middle East and Africa is relatively nascent but steadily expanding, particularly in countries like the UAE and South Africa. The construction and automotive industries are major contributors to market growth in this region. As infrastructure development accelerates and automotive production increases, the demand for acrylic foam tapes for bonding, insulation, and sealing applications rises. However, challenges such as high production costs and limited raw material availability may affect the pace of market expansion.

In Latin America, the acrylic foam tapes market is developing, with Brazil and Mexico leading the region’s growth. The automotive, packaging, and construction sectors are key end-users of acrylic foam tapes. The demand for high-performance tapes in these industries, along with increased focus on energy efficiency and sustainability, is supporting market progress. The market is also benefiting from the growing construction activities and the expansion of the automotive manufacturing base in the region.

Top Key Players and Market Share Insights:

The Global Acrylic Foam Tapes Market Market is highly competitive with major players providing FWA to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Global Acrylic Foam Tapes Market Market. Key players in the Acrylic Foam Tapes Market industry include-

- 3M Company (United States)

- Tesa SE (Germany)

- Mactac (United States)

- Shurtape Technologies LLC (United States)

- Shenzhen Kintec Adhesive Technology Co., Ltd. (China)

- Avery Dennison Corporation (United States)

- Saint-Gobain (France)

- Nitto Denko Corporation (Japan)

- Lintec Corporation (Japan)

- Intertape Polymer Group (Canada)

Acrylic Foam Tapes Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 3,116.22 Million |

| CAGR (2024-2031) | 7.6% |

| By Type |

|

| By Material |

|

| By Adhesive Type |

|

| By Thickness |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Acrylic Foam Tapes Market? +

In 2023, the Acrylic Foam Tapes Market was USD 1,730.80 million.

What will be the potential market valuation for the Acrylic Foam Tapes Market by 2031? +

In 2031, the market size of Acrylic Foam Tapes Market is expected to reach USD 3,116.22 million.

What are the segments covered in the Acrylic Foam Tapes Market report? +

The diagnosis and end-user industry are the segments covered in this report.

Who are the major players in the Acrylic Foam Tapes Market? +

3M Company (United States), Tesa SE (Germany), Avery Dennison Corporation (United States), Saint-Gobain (France), Nitto Denko Corporation (Japan), Lintec Corporation (Japan), Intertape Polymer Group (Canada), Mactac (United States), Shurtape Technologies LLC (United States), Shenzhen Kintec Adhesive Technology Co., Ltd. (China) are the major players in the Acrylic Foam Tapes market.