- Summary

- Table Of Content

- Methodology

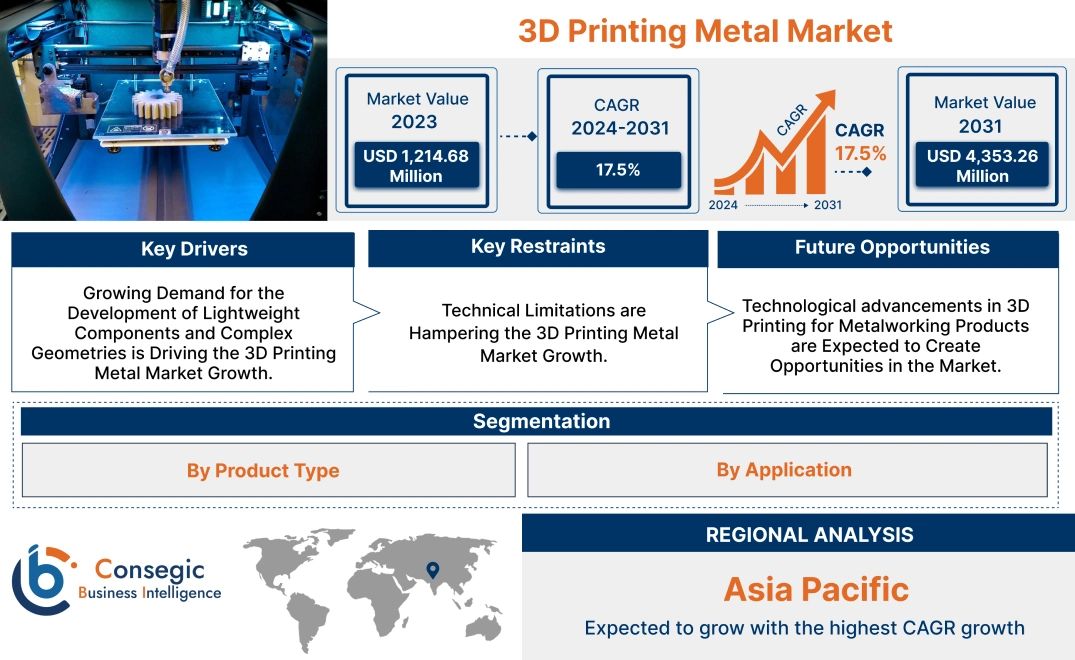

3D Printing Metal Market Size:

3D Printing Metal Market size is growing with a CAGR of 17.5% during the forecast period (2024-2031), and the market is projected to be valued at USD 4,353.26 Million by 2031 from USD 1,214.68 Million in 2023.

3D Printing Metal Market Scope & Overview:

3D printing metal involves the layer-by-layer deposition of metallic materials to create three-dimensional objects. It refers to the use of 3D printing technology to create metal objects. This technology leverages the use of several metal types such as titanium, stainless steel, aluminum, nickel alloy, and others to create metal components. The adoption of 3D printing for metalworking offers numerous advantages such as the creation of intricate designs, optimization of part designs, resulting in lightweight components without compromising strength, the production of highly customized parts, and rapid prototyping among others. These advantages are driving the adoption of 3D printing metal across various sectors, including aerospace & defense, automotive, medical, and others.

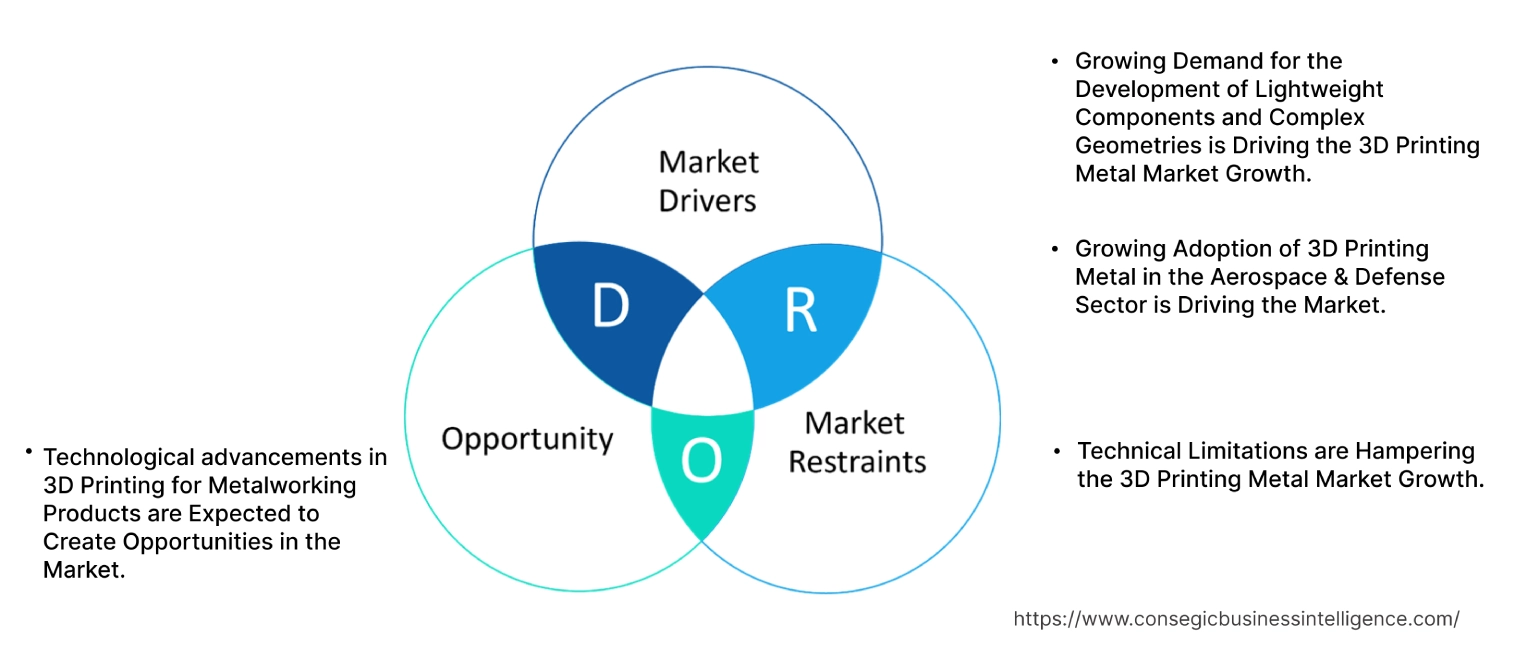

3D Printing Metal Market Dynamics - (DRO) :

Key Drivers:

Growing Demand for the Development of Lightweight Components and Complex Geometries is Driving the 3D Printing Metal Market Growth.

3D printing technology for metal parts offers high flexibility in design and manufacturing, enabling the creation of intricate structures less possible with traditional manufacturing methods. The prospect of efficiency and sustainability has driven a growing emphasis on lightweight across sectors. It offers a suitable solution, enabling the creation of complex lattice structures and optimized designs for significantly lighter components.

3D printing allows engineers to create intricate and complex geometries that optimize specific functions, consolidate parts, and enhance product capabilities. This leads to improved fuel efficiency, enhanced performance, and reduced environmental impact.

- For instance, according to the report published by PwC, 40-50% weight reduction, achieved through redesign and optimization of a simple aluminum sheet metal bracket, translates to USD 700 million in fuel savings over five years for a high-volume single-aisle aircraft. This example highlights the potential of component-level improvements by using 3D printing. Extending this concept to larger-scale aircraft programs, streamlining assembly processes, and reducing the number of 3D-printed metal parts result in substantial savings, estimated at USD10-USD20 billion over the aircraft's lifetime.

The aerospace, automotive, medical, and industrial manufacturing sectors are among the industries benefiting from this technology. As a result, the 3D printing metal market is experiencing significant growth, driven by the increasing requirement for lightweight, complex, and customized components across various sectors.

Growing Adoption of 3D Printing Metal in the Aerospace & Defense Sector is Driving the Market.

The aerospace & defense sector is one of the prominent users of 3D printing technology for metal parts. The aerospace and defense industry involves the development, manufacturing, and maintenance of aircraft, spacecraft, and military equipment. This sector, known for its stringent quality standards and complex component designs, is increasingly adopting 3D printing technology to advance manufacturing processes and product design.

This technology enables the creation of intricate engine metal components such as turbine blades and fuel nozzles with complex internal cooling channels, as well as complex structural components with optimized designs and lightweight materials. By utilizing lattice structures and topology optimization, 3D printing allows for the production of lightweight metal components with high strength-to-weight ratios. Additionally, it accelerates the design and development process through rapid prototyping and functional testing of 3D-printed metal prototypes. Hence, the aerospace & defense sector is emphasizing the adoption of 3D printing metals.

- For instance, in March 2023, Relativity Space launched the world's first rocket made entirely from 3D-printed parts. This innovative rocket, Terran 1, utilizes 3D-printed engines made from a new copper alloy developed by NASA. This alloy, GRCop, offers superior performance at high temperatures, enabling more efficient and reusable rocket components.

As a result, the aerospace and defense sector is a major driver of 3D printing metal adoption, leveraging its benefits for complex components, lightweight designs, rapid prototyping, and efficient manufacturing

Key Restraints :

Technical Limitations are Hampering the 3D Printing Metal Market Growth.

Several technical limitations are hindering its widespread adoption of 3D printing metal technology. One major factor is the limited build volume of many 3D printers for metal, restricting the size and complexity of parts that are produced in a single print. This limits the efficiency of production, especially for large-scale applications. Additionally, achieving consistent mechanical properties, such as strength and ductility is limited, particularly for complex geometries.

Furthermore, designing parts specifically for 3D printing requires specialized knowledge and software tools. Optimizing designs for 3D printing to achieve the appropriate balance of strength, weight, and cost is complex. The range of metal materials suitable for 3D printing is also limited, and not all materials are easily printed with high quality and consistency. High porosity is a common problem in 3D metal printing, as pores in the metal develop due to the powder used in the printing process. Moreover, post-processing steps, such as heat treatment, cleaning, and finishing, are often required to achieve the desired properties and surface finish. These processes are complex and require specialized equipment and expertise.

Future Opportunities :

Technological advancements in 3D Printing for Metalworking Products are Expected to Create Opportunities in the Market.

3D printing for metalworking is undergoing significant technological advancements that are poised to create the potential for the sector. New metal alloys tailored for 3D printing are being developed, offering enhanced properties like strength, durability, and corrosion resistance. Improved printing processes, such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), result in faster print speeds, higher resolution, and the ability to produce larger and more complex components. Additionally, advanced post-processing techniques, such as heat treatment and stress relieving, optimize the mechanical properties of 3D-printed metal parts.

Moreover, AI-powered design tools optimize part designs for 3D printing, reducing material usage and improving performance. Machine learning algorithms analyze and optimize the 3D printing process, leading to higher quality and efficiency. Furthermore, the development of technologically advanced 3D printers for metalworking is expected to boost the adoption of technology.

- For instance, in November 2024, Caracol, a specialist in polymer and composite LFAM hardware, introduced Vipra AM, a new robotic 3D printing metal platform for large-scale metal parts. Caracol’s new robotic platform will be unveiled at Formnext and aims to transform how large-format metal components are made.

As a result, the convergence of advanced materials, improved printing processes, and innovative post-processing techniques is expected to propel the adoption of the technology in the upcoming years further creating 3D printing metal market opportunities and trends.

3D Printing Metal Market Segmental Analysis :

By Product:

Based on product, the market is categorized into titanium, stainless steel, aluminum, nickel alloys, and others.

Trends in the Product:

- Increasing focus on lightweight and high-strength components.

- Growing demand for corrosion-resistant and durable parts.

The titanium segment accounted for the largest market share in 2023.

- Titanium is a dominant segment in the 3D printing metal market demand due to its advantageous properties. Its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility make it suitable for various applications.

- In the aerospace sector, titanium is used to produce lightweight and high-strength components for aircraft and spacecraft. The automotive industry leverages titanium for manufacturing lightweight and high-strength components in racing cars and luxury vehicles. The medical sector benefits from titanium's biocompatibility, using it to create custom implants, dental prosthetics, and surgical instruments.

- The adoption of titanium in 3D printing is driven by several factors, including the increasing requirement for lightweight and high-performance components in the aerospace and automotive industries.

- Advancements in 3D printing technology, such as improved printing techniques and material development, are enabling the production of more complex and reliable titanium parts.

- For instance, in July 2024, Bright Laser Technologies introduced two new additive manufacturing materials, including titanium. BLT-Ti65 powder, a high-temperature titanium alloy, provides excellent strength, plasticity, creep resistance, corrosion resistance, and thermal stability at temperatures up to 650°C, Direct Energy Deposition processes in 3D printing. Targeting applications in aerospace, chemical equipment, and marine industries, the material is said to have been developed to mitigate failures caused by unmelted or partially melted powder particles, inter-track and inter-layer porosity, and cracking.

- Thus, titanium's unique properties and the increasing requirement for lightweight, high-performance components are driving the adoption of the titanium in 3D printing metal market trend.

The stainless-steel segment is expected to grow at the fastest CAGR over the forecast period.

- Stainless steel, renowned for its exceptional mechanical properties, corrosion resistance, and biocompatibility, is a popular material for 3D printing.

- It finds applications in various industries, including aerospace, automotive, medical, and consumer goods. 3D printing enables the creation of intricate and lightweight stainless-steel parts that are difficult to manufacture using traditional methods.

- This technology offers significant advantages such as improved performance, reduced lead times, lower costs, and the ability to produce highly customized parts. Based on the analysis, the increasing demand for customized and high-performance parts is further driving the trends for the use of stainless steel in 3D printing metal market expansion.

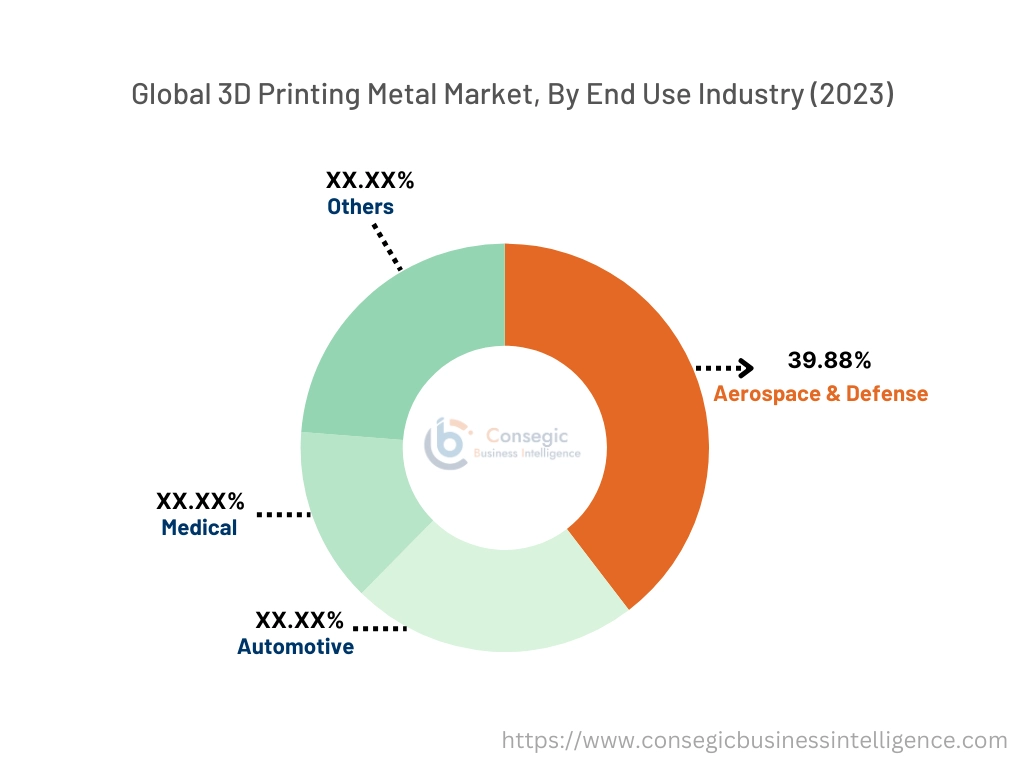

By End Use Industry:

Based on the end-use industry, the market is categorized into aerospace & defense, automotive, medical, and others

Trends in the End-Use Industry:

- Advancements in biocompatible materials enable the production of customized implants and prosthetics.

- Rinsing trends for the use of 3D printing in the production of functional parts and prototypes.

The aerospace & defense segment accounted for the largest market share of 39.88% in the year 2023.

- The aerospace and defense sector is a major end-user of the 3D printing metal market. This sector has been an early adopter of additive manufacturing due to its stringent requirements for lightweight, high-strength, and complex components.

- 3D printing enables the creation of intricate engine components such as turbine blades and combustors, as well as lightweight structural components such as brackets and frames. It also facilitates rapid prototyping and production of custom tooling and fixtures, reducing lead times and costs.

- Moreover, 3D printing allows direct production of end-use parts, eliminating the need for traditional manufacturing processes. This technology offers significant benefits, including lightweight, part consolidation, improved performance, reduced lead times, and optimized supply chains. Hence, end-use companies are increasingly adopting 3D printing technology for metalworking.

- For instance, in August 2024, SpaceX, revealed its Raptor 3 engine for the first time. Produced using advanced manufacturing technologies including extensive 3D printing metal, the company reports that its engineers have been able to move many external parts inward, consolidating and simplifying the design.

- As 3D printing technology continues to advance, its impact on the aerospace and defense sector is growing significantly, advancing the way aircraft, spacecraft, and military equipment are designed, manufactured, and maintained.

The medical segment is expected to grow at the fastest CAGR over the forecast period.

- The medical sector is one of the fastest-growing sectors for 3D printing metal. This innovative approach enables the production of highly customized and complex medical devices and implants, revolutionizing healthcare.

- 3D printing facilitates the creation of patient-specific implants and prosthetics, such as hip, knee, and dental implants, tailored to individual anatomy. Additionally, it enables the production of custom surgical instruments for specific procedures, enhancing surgical precision and patient outcomes.

- A wide range of medical devices, including stents, bone plates, and orthopedic devices, are manufactured using 3D printing.

- The benefits of 3D printing in the medical sector are significant. It enables patient-specific solutions, improves surgical outcomes, reduces manufacturing costs, accelerates development processes, and allows for the creation of complex geometries.

- Based on the analysis, as 3D printing technology advances, its impact on healthcare is expected to grow, leading to improved patient care, and further creating 3D printing metal market opportunities and trends.

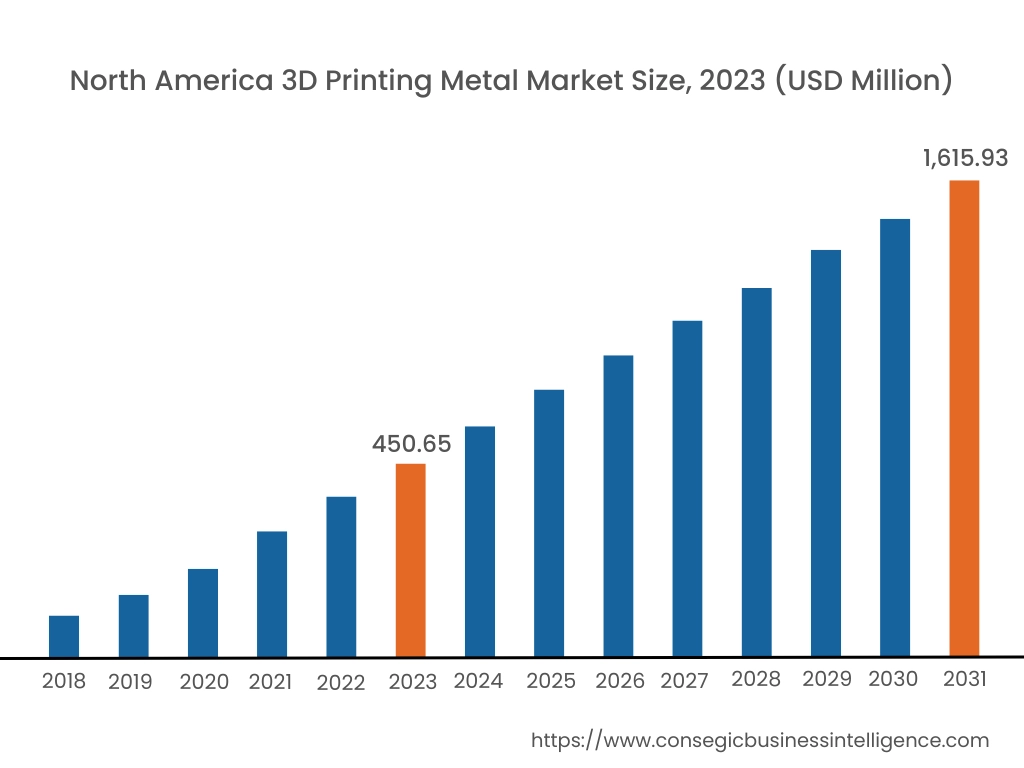

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America accounted for the highest market share at 37.10% and was valued at USD 450.65 Million and is expected to reach USD 1,615.93 Million in 2031. In North America, the U.S. accounted for the highest market share of 73.15% during the base year of 2023. North America holds a dominant position in the global 3D printing metal market share due to several key factors such as the presence of major automotive manufacturers and strong aerospace and defense sector. The region boasts a strong presence of technology leaders and research institutions that are at the forefront of 3 printing innovations. These organizations are actively investing in research and development, leading to the development of advanced 3D printing technologies and materials. These factors, coupled with a robust manufacturing ecosystem and strong government support contribute to North America's leading position in the global 3D printing metal market.

- For instance, in July 2022, the S. Department of Commerce’s National Institute of Standards and Technology (NIST) invested USD 3.7 million in research to advance measurement science and overcome barriers to the widespread adoption of 3D printing metal.

Based on the analysis, collectively aforementioned factors are driving the 3D printing metal market share across North America.

Asia Pacific is experiencing the fastest growth with a CAGR of 17.9% over the forecast period. The region's robust economic growth and rapid industrialization are fueling the demand for advanced manufacturing technologies, including 3D printing metal. Countries such as China, India, and South Korea are experiencing significant industrial expansion, leading to increased adoption of 3D printing metal for various applications. The rising requirement for customized products and rapid prototyping is driving the adoption of these technologies. Governments in the region are actively supporting the development and adoption of advanced manufacturing technologies, including 3D printing metal. They are implementing policies, providing financial incentives, and establishing research and development centers to foster innovation and drive sector growth.

Europe presents a significant contribution to the 3D printing metal market analysis. A key driver of this growth is the strong support from European governments, which have implemented various initiatives and funding programs to promote additive manufacturing. These initiatives encourage research and development, foster innovation, and incentivize the adoption of 3D printing technologies across industries. Furthermore, Europe has a strong focus on industrial applications and manufacturing processes. The region's manufacturing sector is leveraging 3D printing to improve efficiency, reduce production costs, and create complex components. Industries such as automotive, aerospace, and medical are at the forefront of adopting 3D printing metal technologies. As per the analysis, these factors, combined with Europe's strong technological infrastructure and skilled workforce, position the region as a key player in the market.

As per the 3D printing metal market analysis, the Middle East and Africa (MEA) region is a niche market characterized by significant potential. The region's strong oil and gas sector is a significant driver for 3D printing metal adoption. This technology enables the production of complex components for oil rigs, pipelines, and other infrastructure, leading to increased efficiency and reduced downtime. Additionally, the growing healthcare and automotive sectors in the region are also creating potential for 3D printing metal. This technology is used to produce customized medical implants and surgical tools, as well as complex automotive components. Moreover, government bodies across the region are increasingly investing in advanced manufacturing technologies, including 3D printing. These investments are aimed at diversifying economies, creating jobs, and fostering innovation further supporting the 3D printing metal market expansion.

Latin America is rapidly emerging as a significant market for 3D printing metal technologies. The region's expanding aerospace and automotive sectors are driving demand for complex and lightweight components, which are efficiently produced using additive manufacturing techniques. Additionally, the healthcare sector is increasingly adopting 3D printing for the production of customized medical devices and dental prosthetics, improving patient outcomes. Moreover, supportive government initiatives, including investments in research and development, tax incentives, and favorable policies, are further fueling the growth of the 3D printing metal market trends in Latin America. These factors, combined with the region's increasing focus on innovation and technological advancements, position Latin America as a promising market for 3D printing metal technologies, thus influencing the 3D printing metal market.

Top Key Players & Market Share Insights:

The global 3D printing metal market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the 3d printing metal market demand. Key players in the 3D printing metal industry include-

- Wipro Enterprises Pvt. Ltd. (India)

- EOS GmbH (Germany)

- Proto Labs (U.S.)

- General Electric Company (U.S.)

- Markforged (U.S.)

- Renishaw plc. (UK)

- Nikon SLM Solutions AG (Germany)

- Fathom (U.S.)

- Quickparts (U.S.)

- Stratasys (U.S.)

Recent Industry Developments:

Product Launches:

- In November 2024, Caracol, a pioneer in large-format additive manufacturing (LFAM), launched Vipra AM, a novel robotic 3D printing metal platform designed to enhance the production of large-scale metal components. This innovative system leverages wire arc additive manufacturing (WAAM) technology to build complex structures with unmatched efficiency and precision.

- In November 2024, 3D Monotech, a division of Monotech Systems Limited, introduced a novel Markforged FX10 3D printer to the Indian market. This innovative device is capable of printing both metal and advanced composite materials.

- In July 2024, HP's 3D Printing division is using NVIDIA's Modulus AI to enhance its manufacturing capabilities. This AI tool, powered by physics-informed neural networks, integrates physical laws into machine learning models, improving efficiency and accuracy in 3D printing.

- In July 2024, Bright Laser Technologies introduced two new additive manufacturing materials, including titanium. BLT-Ti65 powder, a high-temperature titanium alloy, provides excellent strength, plasticity, creep resistance, corrosion resistance, and thermal stability at temperatures up to 650°C, for Direct Energy Deposition processes in 3D printing.

- In October 2023, AMCM, a prominent German partner of 3D printer manufacturer EOS, launched its latest metal Laser Beam Powder Bed Fusion (PBF-LB) 3D printer, the AMCM M 8K. This cutting-edge technology is poised to revolutionize the additive manufacturing industry.

3D Printing Metal Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 4,353.26 Million |

| CAGR (2024-2031) | 17.5% |

| By Type |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the 3D Printing Metal market? +

In 2023, the 3D Printing Metal market is USD 1,214.68 Million.

Which is the fastest-growing region in the 3D Printing Metal market? +

Asia Pacific is the fastest-growing region in the 3D Printing Metal market.

What specific segmentation details are covered in the 3D Printing Metal market? +

Product and End Use Industry segmentation details are covered in the 3D Printing Metal market.

Who are the major players in the 3D Printing Metal market? +

Wipro Enterprises Pvt. Ltd. (India), EOS GmbH (Germany), Renishaw plc. (UK), and Nikon SLM Solutions AG (Germany) are some of the major players in the market.