- Summary

- Table Of Content

- Methodology

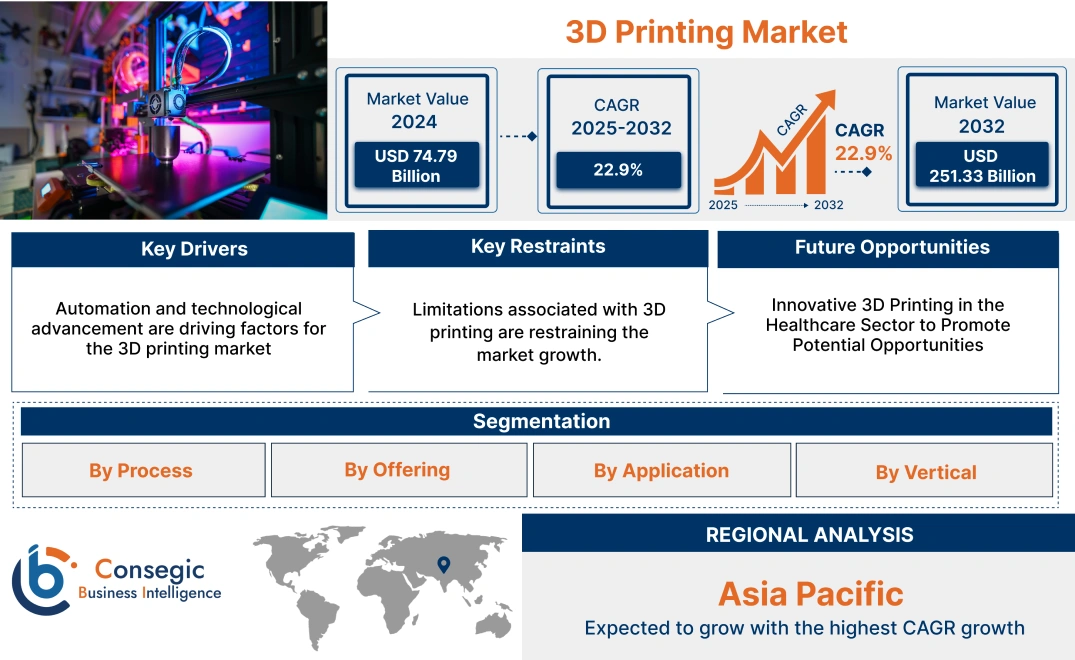

3D Printing Market Size:

3D Printing Market size is estimated to reach over USD 134.27 Billion by 2031 from a value of USD 25.75 Billion in 2023 and is projected to grow by USD 31.20 Billion in 2024, growing at a CAGR of 22.9% from 2024 to 2031.

3D Printing Market Scope & Overview:

3D Printing is the process of creating an object by building it one by one layer at a time to create a physical object from a digital design. 3D printers are used in the manufacturing or prototyping of consumer products, Industrial Products, automotive and aerospace prototypes, medical, healthcare, and dental products, prosthetics, architectural scale models, 3D modeling of fossils and ancient artifacts, movie props, and others. They offer a wide range of benefits such as rapid prototyping, customization and personalization, reduced material waste, on-demand production, low-volume production, design freedom, and innovation. The above benefits are primary determinants for increasing their deployment in automotive, aerospace & defense, healthcare, consumer products, education, energy, and other industries.

3D Printing Market Dynamics - (DRO) :

Key Drivers:

Automation and technological advancement are driving factors for the 3D printing market

In Industry 4.0, 3D printing has emerged as a significant component in transforming manufacturing processes and production lines. The technology is poised for wider adoption in diverse sectors, focusing on practical applications and addressing real-world challenges. Complete workflow automation will aid in the process from product design to printing, with AI-driven design enhancements and reduced manual input. AI and machine learning will refine printing operations, material consumption, and maintenance forecasting, boosting both productivity and output quality. Progress in advanced composites, biocompatible substances, and sophisticated printing methods will facilitate the creation of bigger constructs and encourage acceptance across industries.

- For instance, HP on the opening day of RAPID + TCT 2023 announced a new automation solution to help customers scale 3D printed part production. The products launched were HP jet Fusion 5200 and Endeavor 3D emphasizing labor reduction, as well as providing a cleaner, more efficient flow of material, and facilitating quality control and operational traceability.

- For instance, in November 2023, Markforged launched its newest printer, namely FX10, which is designed to increase productivity and profitability on the factory floor. The FX10 emphasizes built-in automation for quality assurance and print routines, delivering strong and perfect print every time.

Therefore, 3D printing is playing a transformative role in Industry 4.0, driving automated, AI-enhanced manufacturing processes that improve efficiency and quality.

Key Restraints :

Limitations associated with 3D printing are restraining the market growth.

The 3D printing market faces growth challenges due to several inherent limitations in the technology. While 3D printing has revolutionized prototyping and small-scale production across industries, certain technical and practical limitations restrict its broader adoption. Issues such as slow production speeds, limited material variety, and the high cost of specialized materials continue to restrain the market. For example, many 3D printers are limited to specific materials (like plastics or metals), which constrains application diversity, particularly in sectors requiring advanced or composite materials.

Additionally, this printing often struggles with producing high-volume batches due to slower printing speeds compared to traditional manufacturing methods like injection molding or CNC machining. This makes it less cost-effective for large-scale production. Accuracy and surface finish can also be challenging, especially in industries requiring high precision, such as aerospace and medical implants, where post-processing is often needed to achieve the desired quality, adding to costs and production time.

These technological and economic limitations hinder the widespread adoption of printing for large-scale, industrial applications, thereby restraining market growth, especially in cost-sensitive and precision-driven industries.

Future Opportunities :

Innovative 3D Printing in the Healthcare Sector to Promote Potential Opportunities

The innovations in 3D printing in the healthcare sector are witnessing high demand due to factors such as reduced waste generation during the production of medical devices and implants. The sector is moving towards sustainable production methods which are energy-efficient and reduce waste generation. Now organs and implants are constructed with the help of 3D printing, which has proven to be a beneficial tool featuring precision medicines and personalized treatment.

Factors such as preoperative planning, customized surgery, prototyping medical devices, improving surgical instruments, creating prostheses, implants, dentistry, and streamlining drug administration are ongoing trends in the healthcare sector which has immense potential.

- For instance, in November 2023 University of Loughborough researchers developed a 3D printing process that can produce lower-limb socket prostheses outside of the hospital. The result is a fully customized socket that can be produced in as little as eight hours, making the process significantly faster than current methods.

Hence, the adoption of 3D printing in healthcare is accelerating due to its ability to support sustainable production, precision medicine, and personalized treatments.

3D Printing Market Segmental Analysis :

By Process:

Based on the process, the market is segmented into binder jetting, direct energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and VAT polymerization.

The VAT polymerization segment accounted for the largest revenue share in the year 2023.

- VAT polymerization is a highly versatile 3D printing process known for its ability to create highly detailed parts with excellent surface finishes, making it popular across industries like healthcare, automotive, and consumer goods.

- This process includes technologies such as stereolithography (SLA) and digital light processing (DLP), which are widely used for creating prototypes and functional parts that demand high precision.

- Its adoption across various sectors, especially in prototyping and medical applications where fine detail and accuracy are crucial, supports its leading market position.

- For instance, in April 2021 Evonik introduced its new product line of photopolymers for 3D printing namely INFINAM TI 3100 L and INFINAM ST 6100 L, which feature high toughness and impact resistance 3D parts.

- Thus, rising innovation associated with VAT polymerization is driving the 3D printing market trends.

TThe binder jetting segment is anticipated to register the fastest CAGR during the forecast period.

- Binder jetting is gaining traction as a cost-effective 3D printing process capable of producing large volumes of parts quickly. , Unlike other processes that require high energy input, binder jetting builds parts layer-by-layer by binding materials using a liquid agent, making it ideal for applications in the automotive and consumer goods industries.

- The ability to use multiple materials, including metals and ceramics, and its scalability are driving its rapid adoption in industrial settings, especially for functional part manufacturing and mass production.

- Thus, Binder jetting is expected to grow rapidly due to its efficiency, material versatility, and cost-effectiveness in high-volume production, particularly in the automotive and consumer goods sectors.

By Offering:

Based on the offering, the market is segmented into printers, materials, services, and software.

The printers segment accounted for the largest revenue share in the year 2023.

- 3D printers constitute the core of the market, as companies invest in advanced printing systems to enhance in-house prototyping and production capabilities.

- The growing adoption of 3D printers across sectors like automotive, aerospace, and healthcare has fueled this segment's dominance.

- Additionally, advancements in 3D printing technologies, such as multi-material and high-speed printing capabilities, have further encouraged companies to expand their 3D printing infrastructure. As this printing becomes an integral part of industrial manufacturing, the demand for high-performance printers continues to rise.

- For instance, in May 2024, the BMW Group achieved the milestone of production of more than 400,000 parts with the use of 3D printing.

- Thus, rising innovation associated with printers is driving the 3D printing market growth.

The services segment is anticipated to register the fastest CAGR during the forecast period.

- With the increasing adoption of 3D printing, the demand for associated services, such as maintenance, training, custom printing, and consulting, is on the rise.

- Many companies prefer to outsource their printing needs rather than invest in expensive infrastructure, making services a high-growth area.

- Additionally, specialized service providers are expanding their offerings to include design support and end-to-end manufacturing, catering to companies without in-house capabilities.

- The services segment is projected to grow rapidly due to the increasing outsourcing of 3D printing needs and demand for specialized support, maintenance, and consulting services, boosting the 3D printing market expansion.

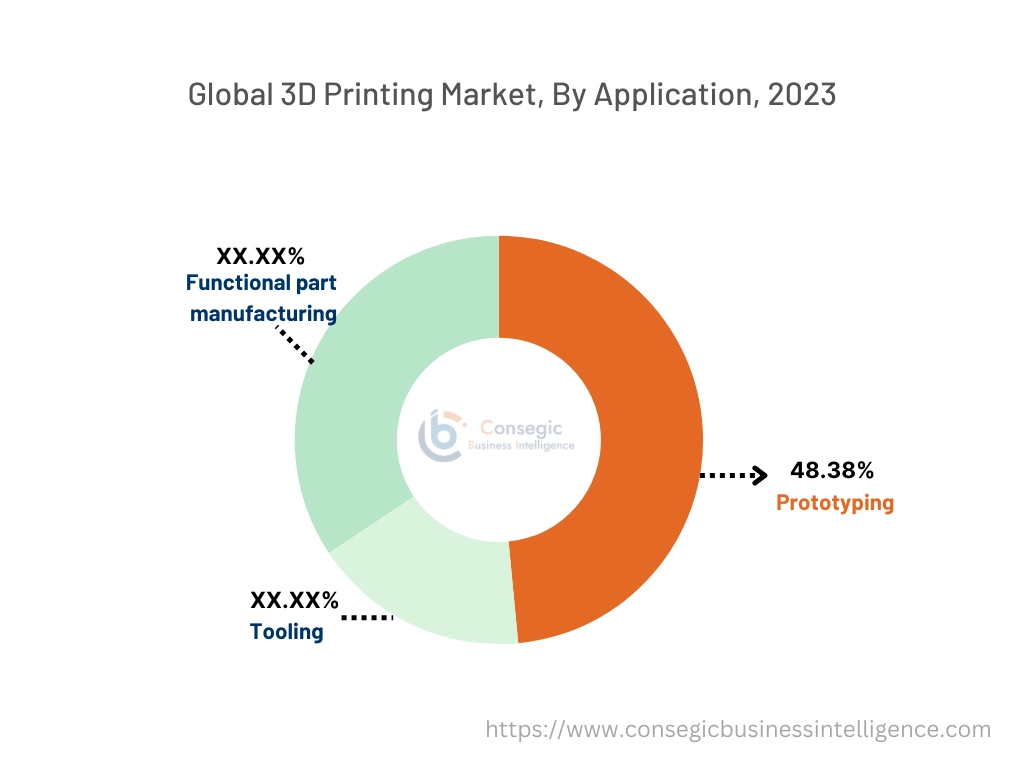

By Application:

Based on the application, the market is segmented into prototyping, tooling, and functional part manufacturing.

The prototyping segment accounted for the largest revenue share of 48.38% in the year 2023.

- Prototyping currently remains the main application of 3D printing in the automotive industry.

- Additionally, several automotive companies are beginning to find innovative end-use applications for 3D printing, signaling an exciting development for the sector.

- For instance, in October 2023, McLaren Racing, a pioneer in carbon-neutral Formula 1 racing, has significantly shifted towards sustainable practices by prioritizing 3D printing for its prototype development, outpacing traditional engineering methods. The team's Southwest London headquarters features a specialized 3D printing lab with over 20 Stratasys printers, producing 9,000 parts yearly, including vital aerodynamic components.

- Thus, the rising utilization of printing for prototyping applications is driving the 3D printing market growth.

The functional part manufacturing segment is anticipated to register the fastest CAGR during the forecast period.

- Functional part manufacturing is an emerging application in 3D printing, allowing industries to produce end-use parts directly.

- The growing capability of printing to create durable, lightweight components, particularly in sectors like aerospace and healthcare, is propelling this segment's growth.

- Functional part manufacturing is gaining traction in high-value, low-volume production settings where customization and material efficiency are prioritized.

- As printing materials and technology continue to advance, its role in producing high-performance, end-use parts is expected to expand.

- Functional part manufacturing is set to grow rapidly as 3D printing advances support end-use part production, offering customized, durable solutions for high-value applications in aerospace and healthcare, boosting the 3D printing market trends.

By Vertical:

Based on the vertical, the market is segmented into automotive, aerospace & defense, healthcare, architecture & construction, consumer products, education, and energy.

The automotive segment accounted for the largest revenue share of the total 3D printing market share in 2023.

- The automotive industry is one of the earliest adopters of 3D printing, using it extensively for prototyping, tooling, and custom part manufacturing.

- Automakers leverage 3D printing for rapid prototyping, allowing them to accelerate design cycles and reduce development costs.

- Additionally, this printing is used to produce lightweight, custom parts in electric vehicles (EVs) and other high-performance applications, contributing to fuel efficiency.

- The increasing focus on EV production and the need for lightweight components have further boosted the demand for printing in the automotive sector.

- The automotive industry leads the market as this printing supports rapid prototyping, custom part production, and lightweight solutions, particularly in electric vehicle manufacturing, driving the 3D printing market demand.

The healthcare segment is anticipated to register the fastest CAGR during the forecast period.

- 3D printing is revolutionizing the healthcare sector by enabling the production of patient-specific medical devices, prosthetics, and implants.

- The technology's ability to create custom-fitted products based on individual patient anatomy has led to its rapid adoption in healthcare.

- Additionally, this printing is being used for surgical planning models, dental devices, and drug delivery systems, which further drives demand in the sector.

- As the technology and materials used in healthcare 3D printing continue to advance, the adoption of this printing for customized patient solutions is expected to grow.

- The healthcare sector is poised for rapid growth in 3D printing adoption due to its capability for patient-specific solutions and the increasing use of 3D printing in medical devices, prosthetics, and surgical planning, boosting the 3D printing market demand.

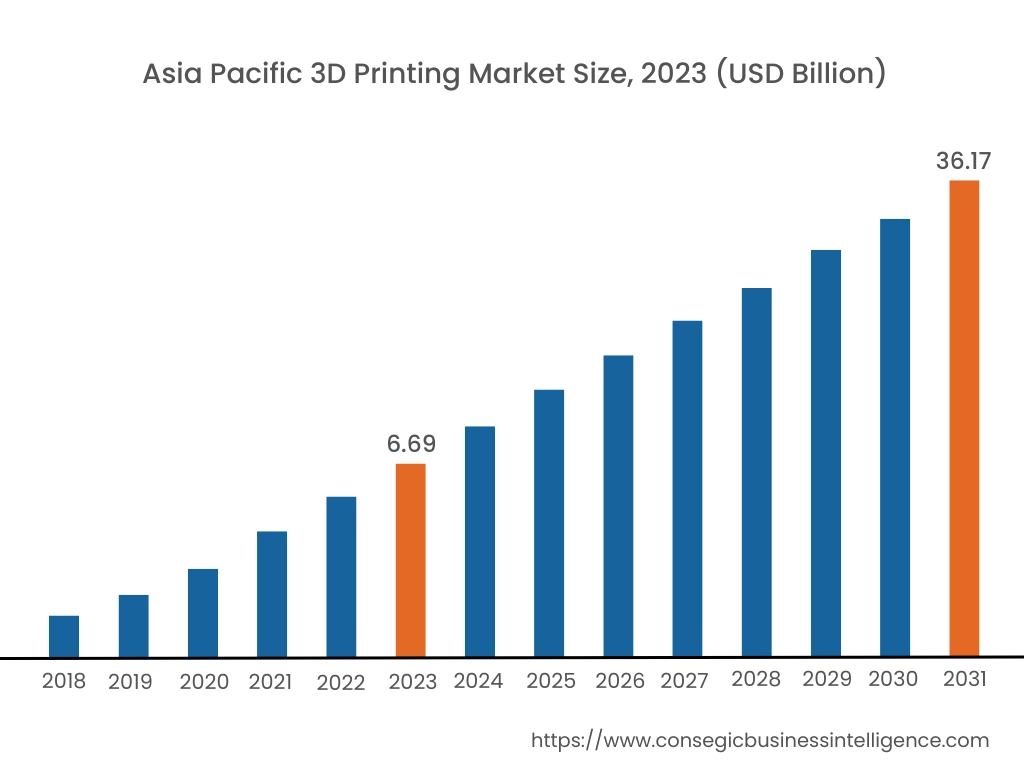

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

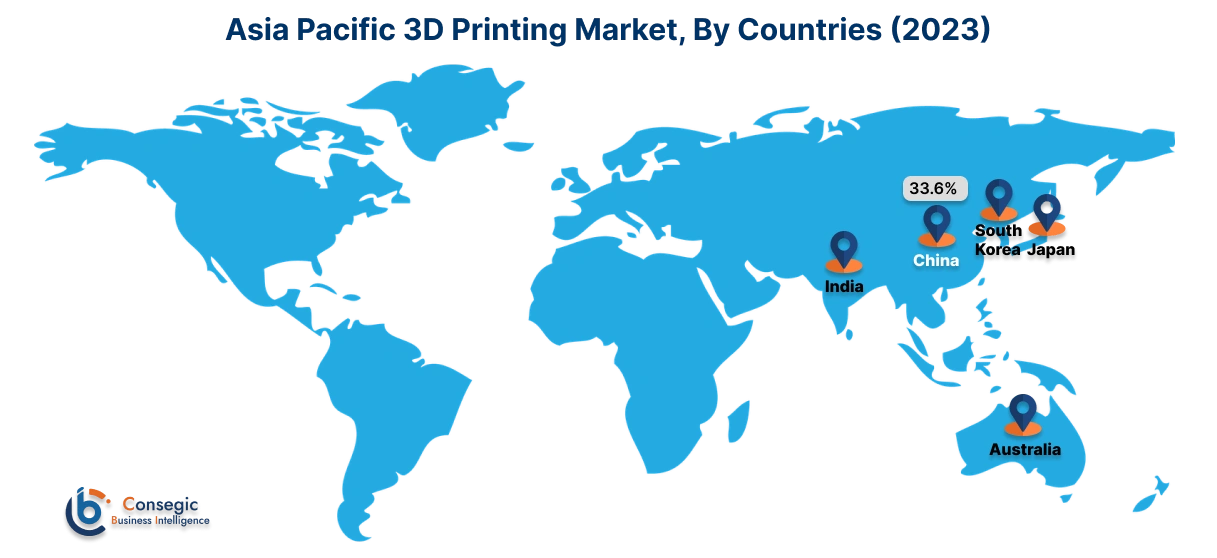

Asia-Pacific region was valued at USD 6.69 Billion in 2023. Out of this, China accounted for the maximum revenue share of 33.6%. Moreover, it is projected to grow by USD 8.13 Billion in 2024 and reach over USD 36.17 Billion by 2031. China leads the region with extensive use of 3D printing in electronics, construction, and consumer goods, supported by government initiatives to promote advanced manufacturing. Japan and South Korea are also heavily invested in 3D printing technology, focusing on high-precision applications for healthcare and automotive. Rapid industrialization, growing adoption in manufacturing, and cost advantages in production boost the market. However, the lack of standardization and skilled professionals in certain areas can limit growth.

North America is estimated to reach over USD 50.08 Billion by 2031 from a value of USD 9.49 Billion in 2023. The market growth for 3D printing is mainly driven by its deployment in automotive, aerospace & defense, healthcare, and other industries.

- For instance, according to the International Organization of Motor Vehicle Manufacturers, the overall automotive production in North America reached 14.79 million in 2022, witnessing a growth of nearly 10% from 13.46 million in 2021.

Furthermore, factors including increasing investments in the field of electric vehicles and air defense systems are projected to drive the market growth in North America during the forecast period.

As per the 3D printing market analysis, Europe is a significant market, led by Germany, the UK, and France, known for their strong industrial and manufacturing capabilities. The region's focus on Industry 4.0 and the adoption of additive manufacturing in sectors such as automotive, aerospace, and healthcare drive growth. The Middle East & Africa (MEA) region is experiencing steady growth in the market, particularly in the UAE and Saudi Arabia, where investments in construction and medical sectors are significant. The UAE's focus on becoming a global leader in 3D-printed construction and Saudi Arabia's investment in technology as part of Vision 2030 drive demand.

Latin America is an emerging market, led by Brazil and Mexico. The region's growth is driven by increasing adoption in the automotive, aerospace, and healthcare industries. Brazil's investments in advanced manufacturing technologies and Mexico's role as a manufacturing hub for North America support the expansion of 3D printing applications.

Top Key Players & Market Share Insights:

The 3D printing market is highly competitive with major players providing 3D printing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global 3D printing market. Key players in the 3D printing industry include-

- Stratasys (US)

- 3D Systems, Inc. (US)

- HP Development Company, L.P. (US)

- EOS GmbH (Germany)

- General Electric (US)

- Materialise NV (Belgium)

- Desktop Metal, Inc. (US)

- Protolabs (US)

- Optomec, Inc. (Mexico)

- Prodways Group (France)

Recent Industry Developments :

Product launches:

- In March 2023, 3D Systems Inc. introduced two innovative printing materials, NextDent Cast and NextDent Base, alongside the NextDent LCD1 printing platform. These new materials are engineered to improve material properties, while the compact, user-friendly NextDent LCD1 printer is set to streamline the additive manufacturing process for customers, facilitating a swifter transition to advanced manufacturing techniques.

3D Printing Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 134.27 Billion |

| CAGR (2024-2031) | 22.9% |

| By Process |

|

| By Offering |

|

| By Application |

|

| By Vertical |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the 3D Printing Market? +

In 2023, the 3D Printing market was USD 25.75 Billion.

What will be the potential market valuation for the 3D Printing by 2031? +

In 2031, the market size of 3D Printing market is expected to reach USD 134.27 billion.

What are the segments covered in the 3D Printing market report? +

The processes, offerings, applications, and verticals are the segments covered in this report.

Who are the major players in the 3D Printing market? +

Stratasys (US), 3D Systems, Inc. (US), HP Development Company, L.P. (US), EOS GmbH (Germany), General Electric (US), Materialise NV (Belgium), Desktop Metal, Inc. (US), Protolabs (US), Optomec, Inc. (Mexico), Prodways Group (France) are the major players in the 3D Printing market