- Summary

- Table Of Content

- Methodology

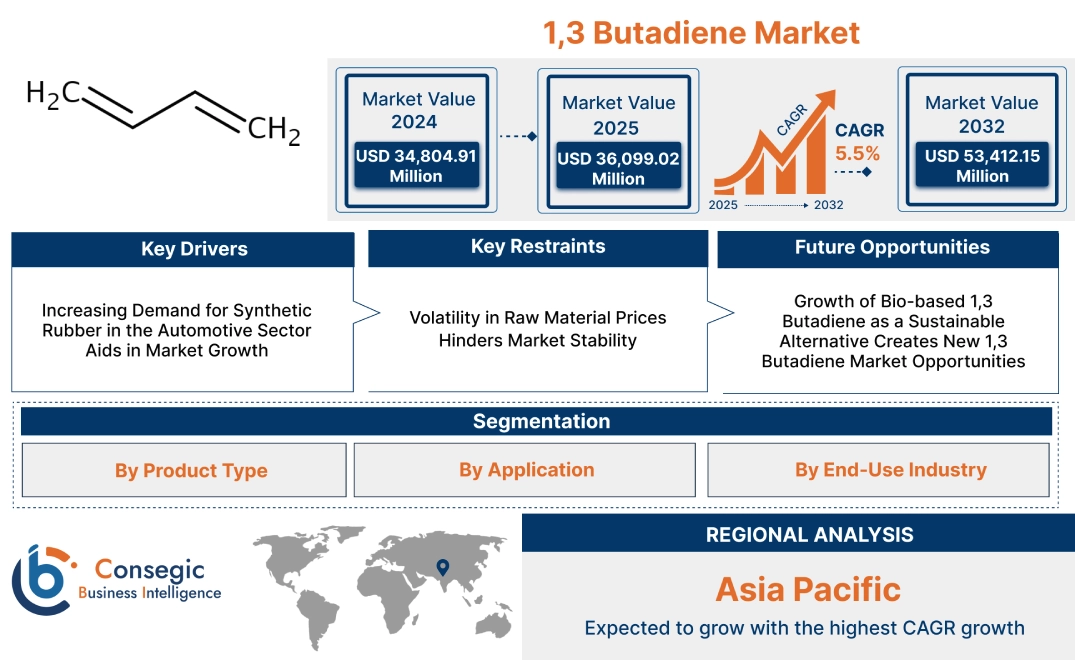

1,3 Butadiene Market Size:

1,3 Butadiene Market size is estimated to reach over USD 53,412.15 Million by 2032 from a value of USD 34,804.91 Million in 2024 and is projected to grow by USD 36,099.02 Million in 2025, growing at a CAGR of 5.5% from 2025 to 2032.

1,3 Butadiene Market Scope & Overview:

1,3 Butadiene is an unsaturated hydrocarbon primarily used as a monomer in the production of synthetic rubber and plastics. It is a colorless, flammable gas with a mild aromatic odor, commonly derived from the cracking process of hydrocarbons. Key characteristics of 1,3 Butadiene include its reactivity and compatibility with other monomers, enabling the synthesis of versatile polymer products. It exhibits excellent thermal stability, making it suitable for high-performance applications. The benefits of 1,3 Butadiene include enhanced elasticity, durability, and chemical resistance when used in synthetic materials. These properties contribute to improved product performance in demanding environments.

1,3 Butadiene is widely applied in the manufacturing of polybutadiene rubber, styrene-butadiene rubber, and nitrile rubber, which are integral to producing tires, adhesives, and industrial components. It is also utilized in the production of ABS (Acrylonitrile Butadiene Styrene) plastics for automotive and electronic applications. End-use industries for 1,3 Butadiene include automotive, construction, consumer goods, and electronics, where its derivatives play a crucial role in ensuring quality and functionality. Its significance in advanced material synthesis positions it as a critical component in industrial and consumer applications.

Key Drivers:

Increasing Demand for Synthetic Rubber in the Automotive Sector Aids in Market Growth

The automotive industry heavily relies on synthetic rubber for manufacturing tires, seals, and other components. As global car production continues to rise, the 1,3 Butadiene market demand for synthetic rubber also escalates. 1,3 Butadiene plays a critical role in the production of styrene-butadiene rubber (SBR) and butadiene rubber (BR), both of which are essential materials for automotive applications. The rising 1,3 Butadiene market trend for fuel-efficient and durable tires is driving the need for these synthetic rubbers, consequently boosting the demand for 1,3 Butadiene. For instance, companies such as Bridgestone and Michelin continue to increase their production of synthetic rubber tires to meet the needs of an expanding automotive market. Therefore, the continuous growth of the automotive sector directly supports the demand for 1,3 Butadiene in synthetic rubber production.

Key Restraints:

Volatility in Raw Material Prices Hinders Market Stability

1,3 Butadiene is primarily derived from petrochemical processes, with its price heavily influenced by fluctuations in crude oil and natural gas prices. The volatile nature of the oil market creates instability in the pricing of 1,3 Butadiene, which can affect its production cost. For example, a rise in crude oil prices can directly increase the cost of 1,3 Butadiene, which may lead to higher production costs for companies that rely on it. This fluctuation in raw material prices can cause uncertainty for manufacturers and hinder 1,3 butadiene market growth, as businesses may struggle to maintain stable margins. Consequently, this price instability presents a significant challenge to the 1,3 Butadiene market growth.

Future Opportunities :

Growth of Bio-based 1,3 Butadiene as a Sustainable Alternative Creates New 1,3 Butadiene Market Opportunities

The growing trend for sustainable and eco-friendly products is expected to drive the development of bio-based 1,3 Butadiene. Researchers and companies are exploring bio-based feedstocks to produce 1,3 Butadiene as a cleaner alternative to the traditional petroleum-derived version. This innovation could help reduce the carbon footprint of industries that depend on 1,3 Butadiene, especially in the automotive and rubber sectors. As governments and organizations push for stricter environmental regulations, the adoption of bio-based 1,3 Butadiene is likely to increase, offering significant trending 1,3 Butadiene market opportunities in the future. For instance, companies like LyondellBasell and Genomatica are investing in bio-based production methods, which could revolutionize the market and contribute to its long-term sustainability. Therefore, the emergence of bio-based 1,3 Butadiene presents a key opportunity for 1,3 Butadiene market expansion and environmental improvement.

1,3 Butadiene Market Segmental Analysis :

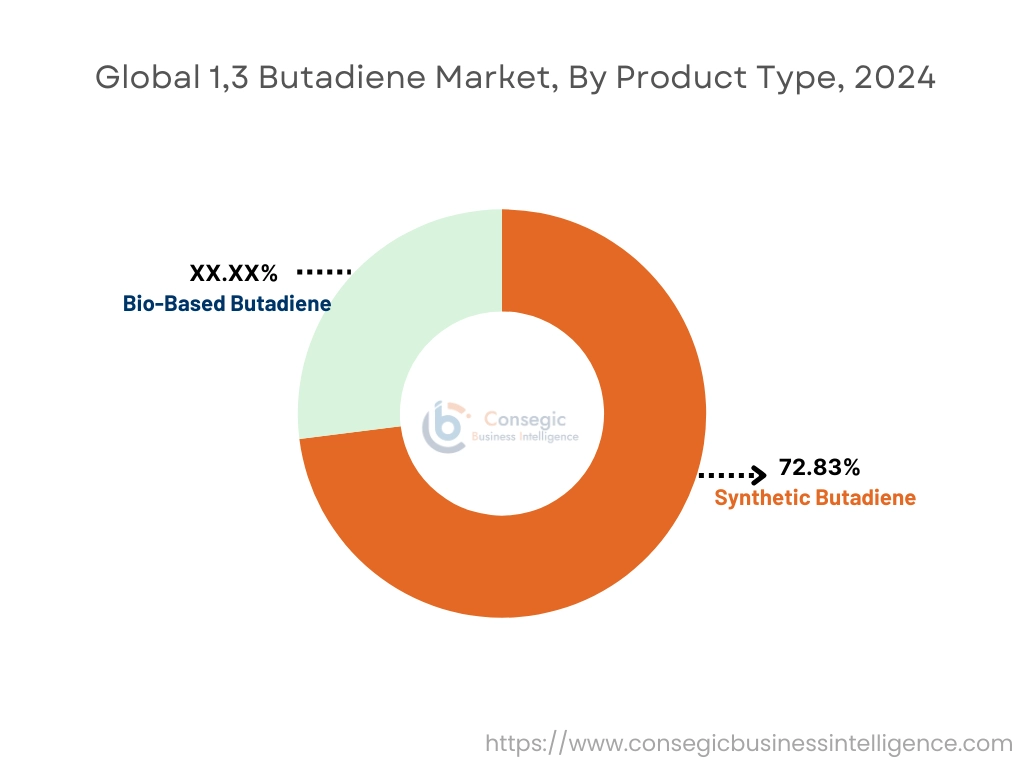

By Product Type:

Based on product type, the market is segmented into Synthetic Butadiene and Bio-Based Butadiene.

The Synthetic Butadiene segment accounted for the largest revenue in the Global 1,3 Butadiene Market share by 72.83% in 2024.

- Synthetic Butadiene is produced from petroleum by-products, specifically through steam cracking of hydrocarbons, making it readily available and cost-effective.

- It is extensively used in the production of synthetic rubbers, primarily in the automotive industry, to manufacture durable tires and other automotive components.

- Synthetic Butadiene is also crucial in producing synthetic latex, resins, and other polymeric materials, contributing to its broad application base.

- It remains the most widely used form of butadiene, benefiting from a well-established supply chain and infrastructure across key global markets.

- Therefore, according to 1,3 Butadiene market analysis, synthetic Butadiene's dominance in the market is driven by its cost-effectiveness, high availability, and extensive use in automotive and industrial applications.

The Bio-Based Butadiene segment is anticipated to register the fastest CAGR during the forecast period.

- Bio-Based Butadiene is derived from renewable sources, such as sugarcane and corn, positioning it as a more sustainable alternative to synthetic butadiene.

- With an increasing focus on sustainability and regulatory pressure to reduce carbon footprints, the adoption of bio-based chemicals, including Bio-Based Butadiene, is on the rise.

- This form of butadiene is used in producing high-quality synthetic rubbers and plastics, particularly in environmentally-conscious automotive products such as green tires.

- Research into more efficient production methods and the growing trend of bio-based product consumption is expected to drive rapid market growth.

- Thus, according to 1,3 Butadiene market analysis, Bio-Based Butadiene segment is poised for up-trend as it meets the increasing trend for sustainable and eco-friendly industrial solutions.

By Application:

Based on application, the market is segmented into Polybutadiene Rubber (PBR), Styrene-Butadiene Rubber (SBR), Acrylonitrile Butadiene Styrene (ABS) Resins, Nitrile Rubber (NBR), and Others.

The Styrene-Butadiene Rubber (SBR) segment accounted for the largest revenue share in 2024.

- SBR is a key component in the production of automotive tires due to its excellent wear resistance, low rolling resistance, and strong performance under high-stress conditions.

- The segment's dominant revenue share is further supported by its use in industrial goods like conveyor belts, gaskets, and hoses, which require durable materials.

- The growing automotive production, especially in emerging economies, significantly contributes to the demand for SBR, particularly for high-performance tires.

- Its applications extend beyond tires, with uses in adhesives, coatings, and footwear, providing consistent demand across diverse industries.

- Therefore, according to market analysis, SBR remains the largest revenue-generating application in the 1,3 Butadiene market due to its versatility, performance in automotive products, and widespread industrial usage.

The Acrylonitrile Butadiene Styrene (ABS) Resins segment is anticipated to register the fastest CAGR during the forecast period.

- ABS resins offer excellent toughness, impact resistance, and heat stability, making them ideal for a variety of applications in the automotive, electronics, and construction industries.

- The automotive sector increasingly utilizes ABS for producing lightweight, durable components, contributing to the rapid growth of this segment.

- As trend for consumer electronics rises, ABS's role in the production of housings, electrical appliances, and other devices further accelerates its market expansion.

- The automotive industry's need for cost-effective, high-performance materials drives the growing consumption of ABS in vehicle components such as dashboards and bumpers.

- Thus, according to market analysis, the expanding use of ABS resins in high-performance applications such as automotive and electronics will continue to propel the segment's rapid growth in the coming years.

By End Use Industry:

Based on end-use industry, the market is segmented into Automotive, Consumer Goods, Construction, Healthcare, and Industrial.

The Automotive segment accounted for the largest revenue share in 2024.

- The automotive industry is the largest consumer of 1,3 Butadiene, particularly for the production of synthetic rubbers used in tires, seals, and gaskets.

- The increasing demand for high-performance tires, which use synthetic rubbers made from 1,3 Butadiene, drives the growth in the automotive sector.

- Automakers also use 1,3 Butadiene-based products in the production of lightweight components to improve fuel efficiency and reduce emissions, in line with stricter regulatory standards.

- The segment benefits from global trends in vehicle production, including the growth of electric vehicles, which require advanced rubber materials for tires.

- Therefore, according to market analysis, automotive sector remains the primary driver for the demand of 1,3 Butadiene, supported by the ongoing need for high-performance materials in vehicle manufacturing.

The Healthcare segment is anticipated to register the fastest CAGR during the forecast period.

- In the healthcare industry, 1,3 Butadiene derivatives like nitrile rubber are used in medical gloves, catheters, and other disposable medical products.

- The growing global emphasis on hygiene, particularly due to the COVID-19 pandemic, has led to increased usage of nitrile gloves, driving demand for 1,3 Butadiene in healthcare applications.

- Additionally, the need for high-quality, durable materials in medical devices and healthcare products further accelerates the segment's growth.

- Advances in medical device technology and increased investments in healthcare infrastructure also contribute to the rapid expansion of the healthcare end-use segment.

- Thus, according to market analysis, healthcare industry's rising focus on disposable, high-performance products ensures the fast growth of 1,3 Butadiene applications in medical and healthcare supplies.

Regional Analysis:

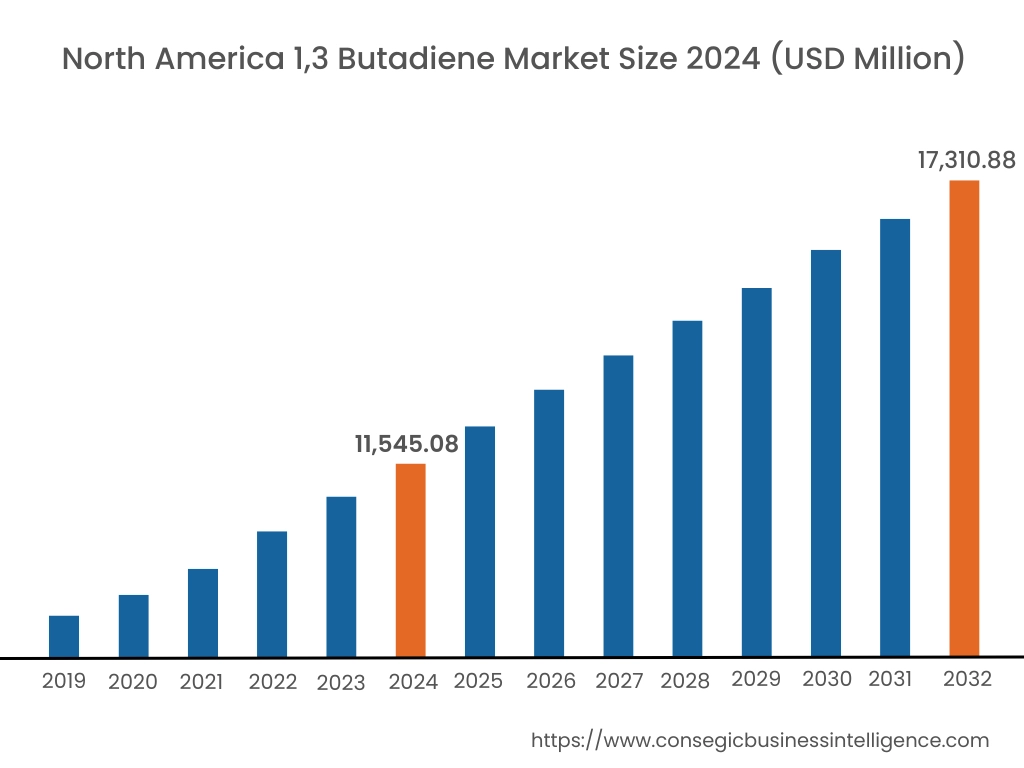

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 11,545.08 Million and is expected to reach USD 17,310.88 Million in 2032. In North America, the U.S. accounted for the highest share of 73.70% during the base year of 2024.

In North America, the 1,3 butadiene market is primarily influenced by the high demand for synthetic rubber, which is crucial for automotive and tire manufacturing. The United States is the leading consumer, supported by the presence of major automotive companies and oil refineries. The market faces regulatory pressures, particularly concerning environmental concerns over emissions from chemical plants and refineries. However, advancements in shale gas production have boosted domestic production capacity.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.9% over the forecast period.

Asia-Pacific holds the largest share of the 1,3 butadiene market. China is the largest consumer due to its massive automotive industry and the demand for synthetic rubber. India, Japan, and South Korea also contribute significantly to market expansion, supported by strong industrial sectors. This region is a key player in the petrochemical industry, with numerous refineries and petrochemical plants increasing 1,3 butadiene production. Economic growth, infrastructure development, and industrialization continue to support high demand.

In Europe, the 1,3 butadiene market is driven by the automotive and tire industries, with Germany being the primary consumer. Europe also has strict environmental regulations, which impact the production processes of 1,3 butadiene. The region's market is transitioning towards sustainable practices, including the increased use of bio-based and recycled materials. The production of 1,3 butadiene in Europe is concentrated in countries with large petrochemical sectors, such as Germany, France, and Belgium.

The Middle East has a strong 1,3 butadiene market due to the region's extensive oil and gas resources. Countries like Saudi Arabia and the UAE benefit from cheap feedstock, which enables them to maintain low production costs. These regions export large quantities of 1,3 butadiene, particularly to Asia-Pacific and Europe. The African market remains relatively small but is gradually developing as industrialization increases in key markets like South Africa.

Latin America’s 1,3 butadiene market is concentrated in Brazil and Mexico, where automotive and tire manufacturing industries contribute to demand. The region also benefits from its proximity to the United States, which influences the trade of raw materials. However, political instability and economic volatility in some countries limit market growth. The focus is mainly on expanding production capacity and enhancing petrochemical infrastructure in Brazil and Mexico.

Top Key Players & Market Share Insights:

The Global 1,3 Butadiene Market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Global 1,3 Butadiene Market. Key players in the 1,3 Butadiene industry include-

- Royal Dutch Shell (Netherlands)

- ExxonMobil Corporation (United States)

- Sabic (Saudi Arabia)

- Chevron Phillips Chemical Company (United States)

- Evonik Industries AG (Germany)

- Braskem (Brazil)

- LyondellBasell Industries (Netherlands)

- INEOS Group (United Kingdom)

- Reliance Industries Limited (India)

- LG Chem Ltd. (South Korea)

1,3 Butadiene Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 53,412.15 Million |

| CAGR (2025-2032) | 5.5% |

| By Product Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the 1,3 Butadiene Market? +

In 2024, the 1,3 Butadiene Market was USD 34,804.91 million.

What will be the potential market valuation for the 1,3 Butadiene Market by 2032? +

In 2032, the market size of 1,3 Butadiene Market is expected to reach USD 53,412.15 million.

What are the segments covered in the 1,3 Butadiene Market report? +

The product type, application, and end-user industry are the segments covered in this report.

Who are the major players in the 1,3 Butadiene Market? +

Royal Dutch Shell (Netherlands), ExxonMobil Corporation (United States), Braskem (Brazil), LyondellBasell Industries (Netherlands), INEOS Group (United Kingdom), Reliance Industries Limited (India), LG Chem Ltd. (South Korea), Sabic (Saudi Arabia), Chevron Phillips Chemical Company (United States), Evonik Industries AG (Germany) are the major players in the 1,3 Butadiene market.